High-thermal-conductivity composite phase change energy storage microcapsules used at normal temperature and preparation method thereof

A composite phase transition and high thermal conductivity technology, applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of affecting the utilization rate of enthalpy, poor shapeability, poor thermal conductivity, etc. Transfer and conversion, low thermal expansion coefficient, good energy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

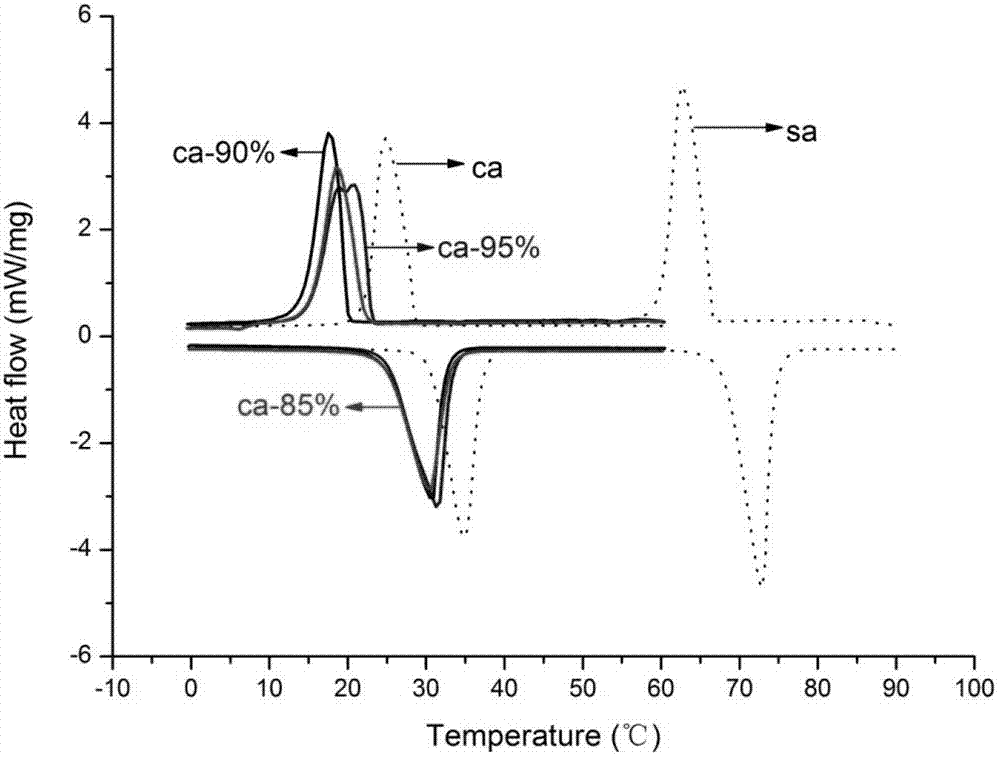

[0034] (1) Set the mass ratio of octanoic acid and palmitic acid to 9:1, fully mix them at a constant temperature of 40-100°C for 0.5-5 hours, and use the product as a capsule core material for future use;

[0035] (2) Add surfactant, water, capsule core material, etc. into the beaker to adjust the pH value to 3-5, and emulsify for 3-10 minutes to make a uniform emulsion;

[0036] (3) Slowly add a certain amount of tetraethyl orthosilicate (the ratio of core to ester is 0.5:1) to the above-mentioned emulsion, react at a certain temperature for 1 to 6 hours, age, and finally wash and dry to make high-grade Heat conduction phase change energy storage microcapsules.

Embodiment 2

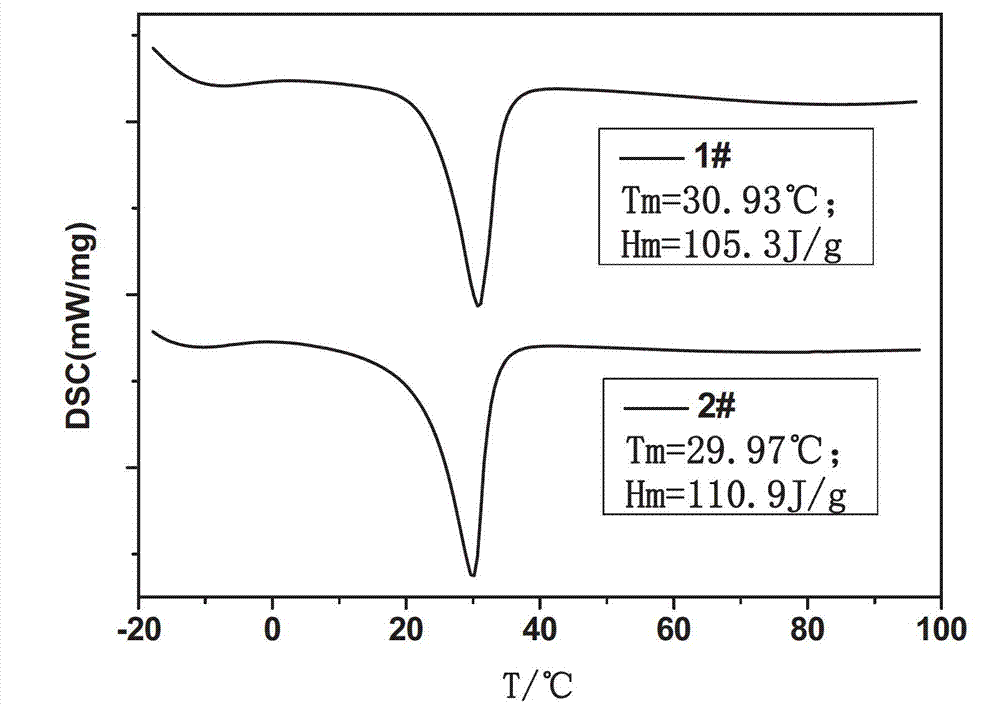

[0038] (1) Set the mass ratio of capric acid and stearic acid to 9:1, and mix them thoroughly at a constant temperature of 40-100°C for 0.5-5 hours, and the product is used as a capsule core material for later use;

[0039] (2) Add surfactant, water, capsule core material, etc. into the beaker to adjust the pH value to 3-5, and emulsify for 3-10 minutes to make a uniform emulsion;

[0040] (3) Slowly add a certain amount of tetraethyl orthosilicate (the core-ester ratio is 1:1) dropwise into the above-mentioned emulsion, react at a certain temperature for 1 to 6 hours, age, and finally wash and dry to make high-grade Heat conduction phase change energy storage microcapsules.

Embodiment 3

[0042] (1) Set the mass ratio of PEG600 and PEG1000 to 9:1, and mix them thoroughly at a constant temperature of 40-100°C for 0.5-5 hours, and use the product as a capsule core material for later use;

[0043] (2) Add surfactant, water, capsule core material, etc. into the beaker to adjust the pH value to 3-5, and emulsify for 3-10 minutes to make a uniform emulsion;

[0044] (3) Slowly add a certain amount of tetraethyl orthosilicate (the ratio of core to ester is 1.5:1) dropwise to the above emulsion, react at a certain temperature for 1 to 6 hours, age, and finally wash and dry to make high temperature Heat conduction phase change energy storage microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com