Preparation method of plasticized, copolymerized and modified organic glass

A technology of plexiglass and copolymerization modification, which is applied in the field of super tough and high transmittance plexiglass, which can solve the problems of easy generation of silver streaks and cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Step 1: Wash and dry two pieces of 120x120x3mm silicon glass, wrap a square rubber strip with tin foil, the size of the internal cavity is 8x8x3mm, stick one side of the rubber strip to a piece of silicon glass with glass glue, and then cover Put another piece of glass on it, clamp it with clips, and set it aside.

[0023] Step 2: Stir and mix 10g of methyl methacrylate (MMA) distilled under reduced pressure and 0.01g of initiator azobisisobutyronitrile (AIBN) with a glass rod, then pour into a clean 100ml round bottom flask , Stir and heat up to 85 ° C, stop heating when the solution becomes viscous, cool to room temperature, that is, prepolymer.

[0024] Step 3: Pour the prepolymer into the mold made in step 1, clamp and seal it, put it in a 50°C oven for slow polymerization for 24 hours, and when the polymer becomes a solid gel, raise the temperature to 100°C and then polymerize for 1~2 hours, so that It is fully polymerized, then gradually cooled to room temperatur...

example 2

[0026] The operation is the same as in Example 1, except that when the monomer methyl methacrylate (MMA) is added in step 2, the comonomer n-butyl acrylate (BA) is added, and the amount of the initiator and other reagents remains unchanged.

example 3

[0028] The operation is the same as in Example 2, except that the plasticizer dioctyl phthalate is added when the monomer methyl methacrylate (MMA) and the comonomer n-butyl acrylate (BA) are added in step 2 (DOP), the amount of initiator and other reagents was unchanged.

[0029] Example 4~8:

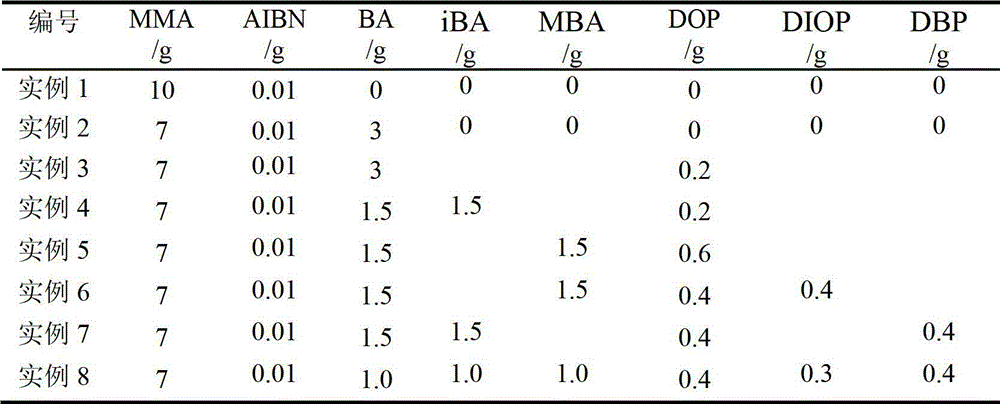

[0030] The operation is the same as in Example 3, except that the mass ratios of MMA, BA, iBA, DOP, DIOP and DBP added in step 2 are different, as shown in Table 1.

[0031] The material proportion of table 1 example 1~7

[0032]

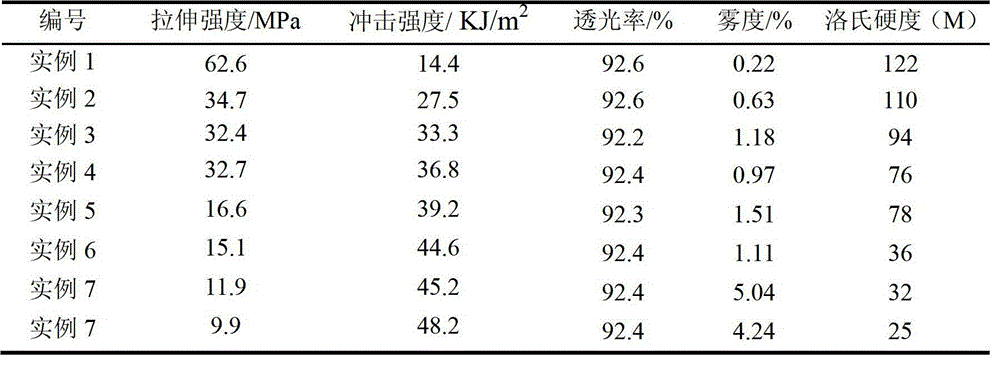

[0033] Table 2 Sheet properties

[0034]

[0035] It can be seen from the test data in Table 2 that: adding 3g of comonomer n-butyl acrylate, the impact strength of the plate is increased by 14.4KJ / m 2 Increased to 27.5KJ / m 2 , increased by 91%, and then added 0.2gDOP, the impact strength increased by 21%; the tensile strength decreased significantly, and the impact strength was less than 30MPa after the DOP was greater than 0.2g; the light transmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com