Corona-resistant polyimide film material and preparation method thereof

A polyimide film and polyimide resin technology, which is applied in the field of polyimide-containing film materials, can solve the problems of inability to meet mass production needs, many production processes, and limited production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

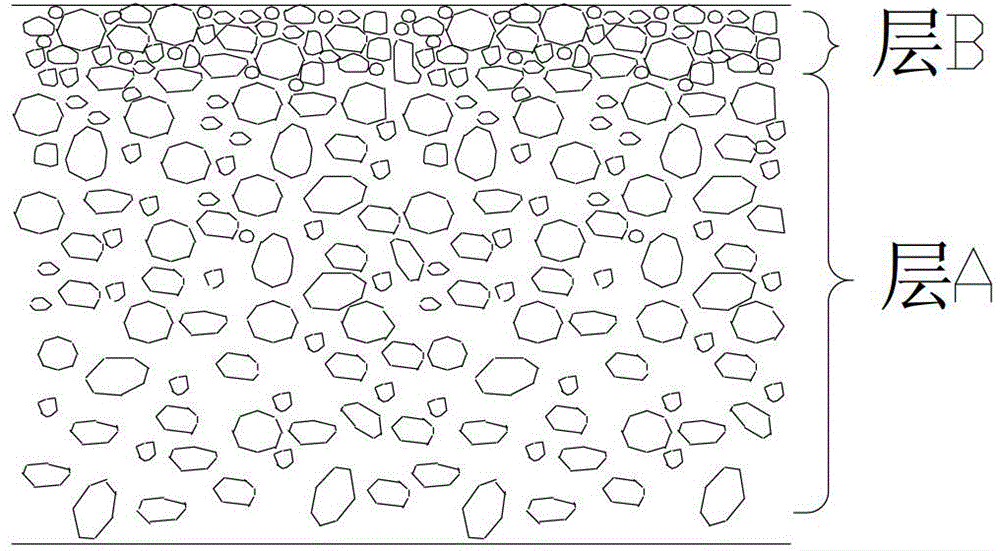

[0071] Pyromellitic dianhydride and 4.4' diaminodiphenyl ether were reacted in dimethylacetamide at a molar ratio of 0.99:1 to prepare 100 kg of polyamic acid resin solution with a viscosity of 100,000 centipoise and a solid content of 20 %.

[0072] Add 2.8kg of 30nm silica, 4.5kg of ethanol, and 0.056kg of aminopropyltriethoxysilane into 2.644kg of dimethylacetamide, and disperse with high-speed stirring at 3000 rpm to prepare 10kg of slurry ①.

[0073] Add 2.4kg of 400nm alumina, 4.5kg of ethanol, and 0.048kg of aminopropyltriethoxysilane into 3.052kg of dimethylacetamide, and disperse with high-speed stirring at 3000 rpm to prepare 10kg of slurry②.

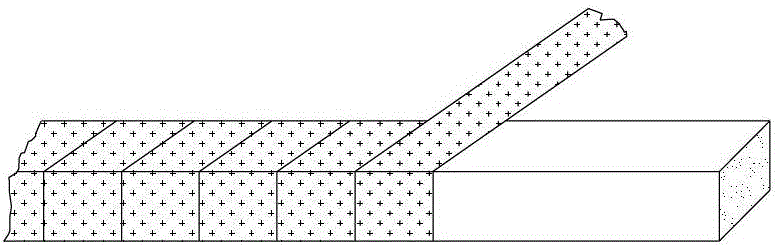

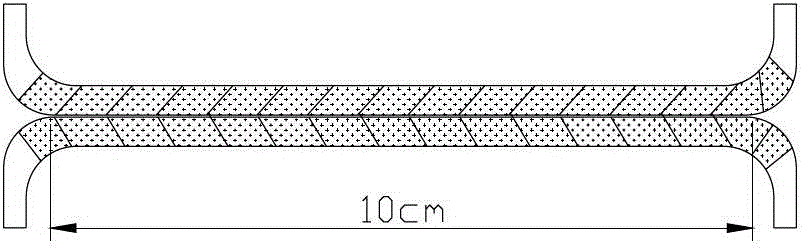

[0074] Add the slurries ① and ② into the prepared polyamic acid resin solution, and stir for 5 hours at 100 rpm. The obtained polyamic acid mixed resin is transported to the salivating die head through the pipeline, and then passes through the endless steel belt and is removed by the solvent. , to obtain a polyimide salivatio...

Embodiment 2

[0124] Pyromellitic dianhydride and 4.4' diaminodiphenyl ether were reacted in dimethylacetamide at a molar ratio of 0.99:1 to prepare 100 kg of polyamic acid resin solution with a viscosity of 100,000 centipoise and a solid content of 20 %.

[0125] Add 2.8kg of 30nm silica, 4.5kg of 2-pentanone, and 0.056kg of aminopropyltriethoxysilane into 2.644kg of dimethylacetamide, and disperse with high-speed stirring at 3000 rpm to prepare 10kg of slurry ①.

[0126] Add 2.4kg of 400nm alumina, 4.5kg of 2-pentanone, and 0.048kg of aminopropyltriethoxysilane into 3.052kg of dimethylacetamide, and disperse with high-speed stirring at 3000 rpm to prepare 10kg of slurry②.

[0127] Add the slurries ① and ② into the prepared polyamic acid resin solution, and stir for 5 hours at 100 rpm. The obtained polyamic acid mixed resin is transported to the salivating die head through the pipeline, and then passes through the endless steel belt and is removed by the solvent. , to obtain a polyimide s...

Embodiment 3

[0134] Pyromellitic dianhydride and 4.4' diaminodiphenyl ether were reacted in dimethylacetamide at a molar ratio of 0.99:1 to prepare 100 kg of polyamic acid resin solution with a viscosity of 100,000 centipoise and a solid content of 20 %.

[0135] Add 2.8kg of 30nm silica, 4.5kg of ethanol, and 0.056kg of isopropoxytricarboxylic acyl titanate into 2.644kg of dimethylacetamide, and disperse with high-speed stirring at 3000 rpm to prepare 10kg of slurry①.

[0136] Add 2.4kg of 400nm alumina, 4.5kg of ethanol, and 0.048kg of isopropoxytricarboxylic acyl titanate into 3.052kg of dimethylacetamide, and disperse with high-speed stirring at 3000 rpm to prepare 10kg of slurry②.

[0137] Add the slurries ① and ② into the prepared polyamic acid resin solution, and stir for 5 hours at 100 rpm. The obtained polyamic acid mixed resin is transported to the salivating die head through the pipeline, and then passes through the endless steel belt and is removed by the solvent. , to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com