Cistanche cell disruption method and buccal tablet prepared by cistanche micropowder obtained by method

A technology of cistanche and cells, which is applied in the field of medicinal plant application research, can solve the problems of high production cost, unpleasantness, and large particles of cistanche powder, and achieve the effects of convenient consumption, small particle size, and avoiding reactions such as oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

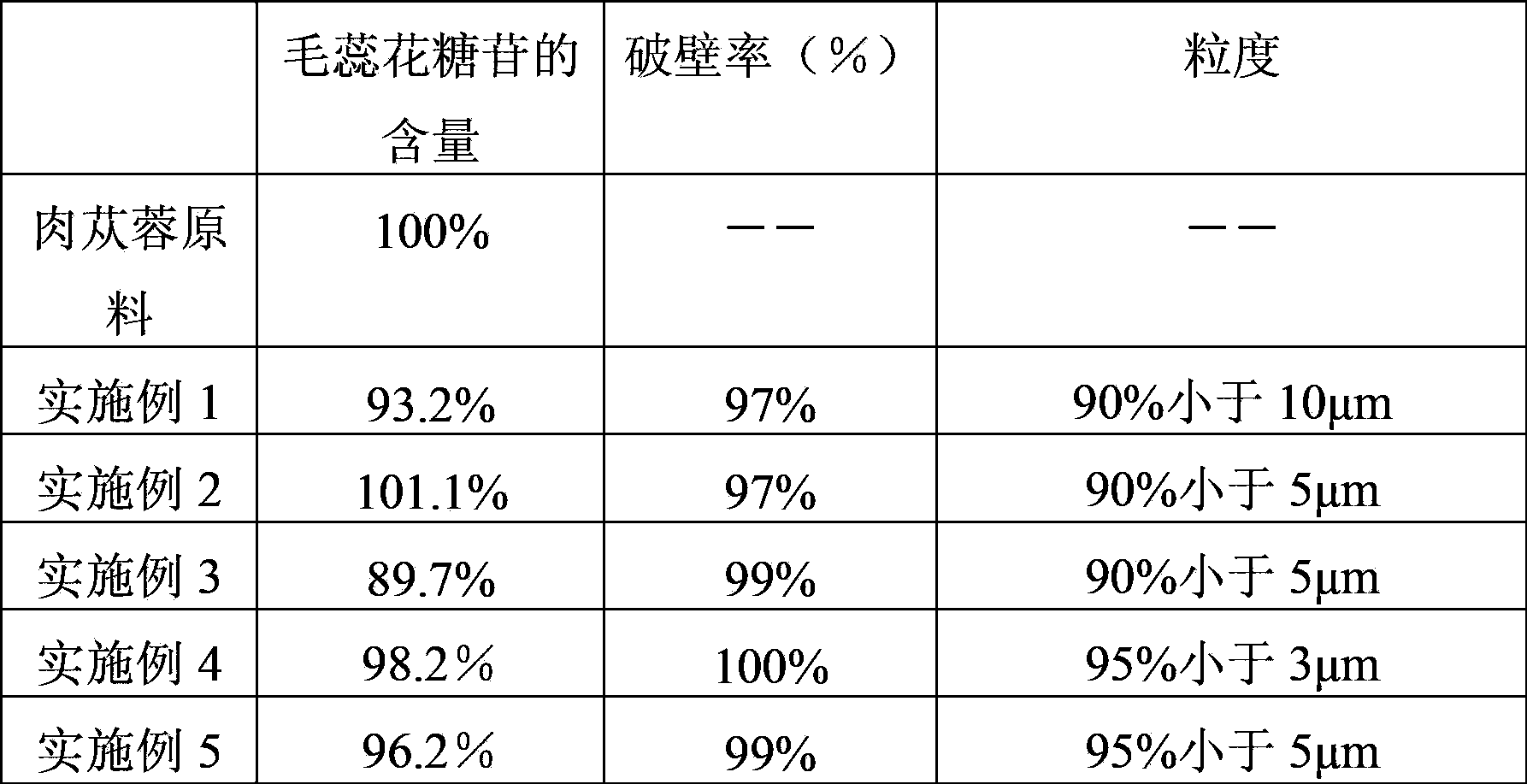

[0021] Example 1 Weigh 500g of Cistanche deserticola, wash and chop it, and dry it; use a commercially available low-temperature pulverizer for Chinese herbal medicines for coarse powder at a low temperature below -10°C; freeze the coarse powder at -30°C and put it into a vibrating wall breaker for another Dry wall breaking, usually dry wall breaking means that the breaking time without solvent is 30 minutes to 60 minutes, (equipment model: SQW-25 Sanqing Micro Powder Vibration Crusher), after freezing and crushing, repeat the operation 2-4 Second, this is conducive to better wall breaking and achieving the desired particle size. The cistanche micropowder obtained is put into ultra-high pressure equipment, sterilized under high pressure treatment for 20 minutes under 350Mpa of nitrogen gas, and the pressure is released instantaneously. After repeated freezing and low-temperature crushing of Cistanche deserticola, high pressure is used to release the pressure instantaneously du...

Embodiment 2

[0022] Example 2 Weigh 500g of Cistanche deserticola, wash and slice it, and dry it; coarse powder or directly wash the fresh cistanche deserticola and crush it with a crusher; use the wet method to break the wall of the prepared material; here it is represented by a colloid mill Conduct the test: mix the coarse powder and water at a weight ratio of 1:1, put them into the colloid mill, adjust the gap between the stator and the rotor of the colloid mill to 2-10 microns, and grind for 30 minutes to 90 minutes, depending on the model of the colloid mill : JMS-180, provided by Langfang Lijie Machinery Factory; then the prepared mixture of substances and liquids was sterilized by high-pressure treatment at 200Mpa (hydrostatic pressure) for 20 minutes, and the pressure was released instantly. The wall breaking rate was about 97%. The particle size diameter is about 1-3 microns, and the homogeneity reaches 98%. Finally, it is freeze-dried. Here, the low-temperature negative pressure d...

Embodiment 3

[0023] Embodiment 3 Weigh 500g Cistanche deserticola, wash and slice it, and dry it; the coarse powder or directly wash the fresh cistanche deserticola and break it with a crusher; use the wet method to break the wall of the prepared coarse powder; On behalf of the test;: mix the coarse powder and water with a weight ratio of 1:1, put it into the colloid mill to break the wall; adjust the gap between the colloid mill stator and the rotor to 2-10 microns, and grind for 30-90 minutes. The obtained mixture of substances and liquids was ultrasonically treated with an ultrasonic wall breaking machine, and an ultrasonic cell pulverizer SL-1200D provided by Nanjing Shunliu Instrument Co., Ltd. was used for 15-30 min with an ultrasonic wave of 10-60 kHz. In this way, the wall-breaking rate can be improved more effectively and the particle size can be minimized. The obtained material is sterilized under high-pressure treatment at 350Mpa (hydrostatic pressure) for 30 minutes, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com