Full-function electric-energy quality comprehensive test platform

A technology of power quality and comprehensive testing, applied in the direction of measuring electrical variables, components of electrical measuring instruments, measuring electricity, etc., can solve the problems of current harmonics, large volume, insufficient output power, etc., and reduce the output voltage change rate Stress, improve dynamic performance and steady-state accuracy, and achieve the effect of no static error control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

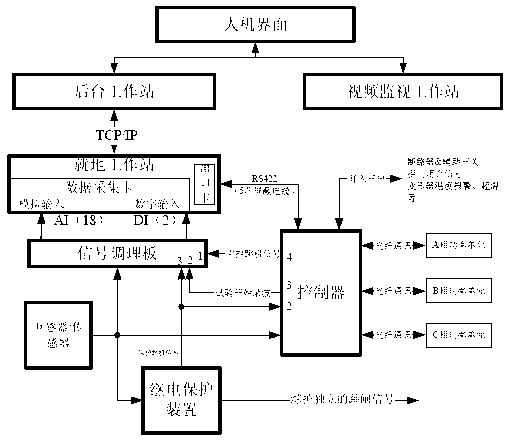

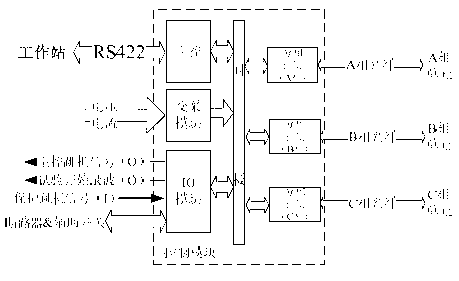

[0032] see figure 1 The structure of the power quality comprehensive monitoring system proposed by the present invention is composed of a man-machine interface, a background workstation, an on-site workstation, a video monitoring workstation, a signal conditioning board, a control module, and a relay protection device. Among them, the 16-channel high-speed data acquisition card and 485 / 422 serial port card of the PCI bus are inserted in the local workstation, which undertakes the signal wave recording function and the communication with the controller. The / IP protocol is connected to the background workstation. The background workstation is responsible for man-machine interface, wave recording signal operation and display, fault record, background communication, start, stop and other control functions. The signal conditioning board realizes the interface between the output signal of the secondary side of the high voltage transformer and the switch signal and the data acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com