Dry intensifier for paper making, and preparation method and application thereof

A technology of dry strength agent and oxidant, which is applied in papermaking, reinforcing agent addition, textiles and papermaking, etc. It can solve the problems of product storage stability deterioration, need to be improved, and low stability, etc., to achieve enhanced enhancement effect, enhanced effect, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

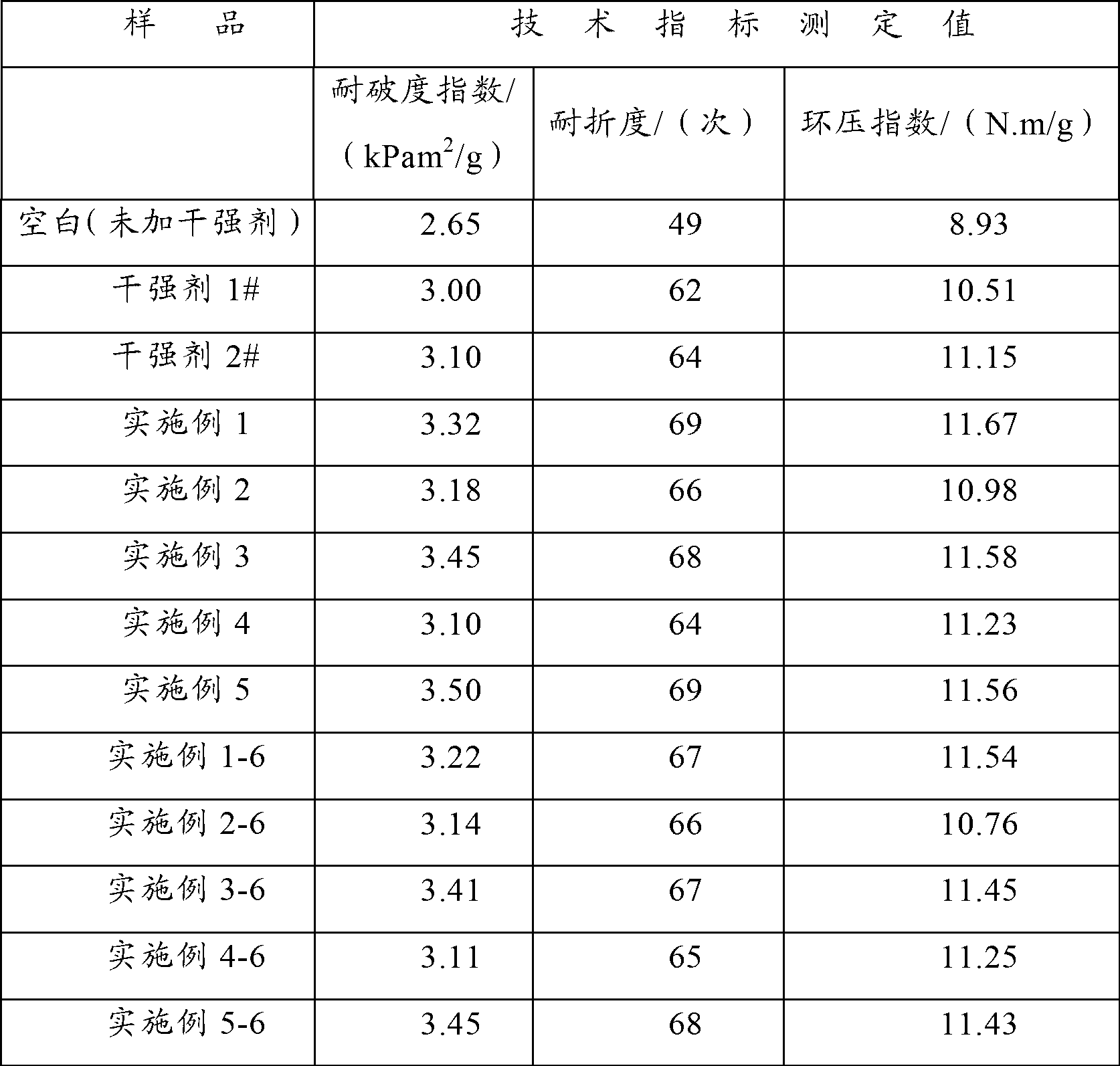

Examples

Embodiment 1

[0021] Weigh 738kg of deionized water, 166.8kg of acrylamide monomer (AM), 16kg of dimethyl diallyl ammonium chloride (DMDAAC), 7kg of acrylic acid, 6.7kg of methyl etherified methylol acrylamide monomer, 1.5kg Polyethylene glycol dimethacrylate, with a total monomer weight of 198kg, was made into a solution, and the pH value was adjusted to about 3-5, then 195g of sodium bisulfite was added, stirred and dissolved, and nitrogen gas was passed for 30 minutes for later use. 18% by weight of the monomer solution was added to the reactor as a kettle material, and the remaining monomer solution was added to the dripping tank 1 as a dripping solution for subsequent use.

[0022] Add 390g of ammonium persulfate into 65kg of water to form a solution, and add it to the dropping tank 2.

[0023] The temperature of the reactor material was raised to 40° C., and the solutions in the tanks 1 and 2 were started to be added dropwise. It is required to finish dripping in 180min. After the d...

Embodiment 2

[0025] Weigh 738 kg of deionized water, 166.8 kg of acrylamide monomer (AM), 16 kg of dimethyl diallyl ammonium chloride (DMDAAC), 7 kg of acrylic acid, 8 kg of methyl etherified methylol acrylamide monomer, 1.5 kg of poly Ethylene glycol dimethacrylate, a total of 199.3kg of monomers, made into a solution, adjusted the pH value to about 3-5, then added 195g of sodium bisulfite, stirred and dissolved, and passed nitrogen gas for 30 minutes for later use. 15% by weight of the monomer solution was added to the reactor as a kettle material, and the remaining monomer solution was added to the dripping tank 1 as a dripping solution for subsequent use.

[0026] Add 390g of ammonium persulfate into 65kg of water to form a solution, and add it to the dropping tank 2.

[0027] The temperature of the reactor material was raised to 40° C., and the solutions in the tanks 1 and 2 were started to be added dropwise. It is required to finish dripping in 180min. After the dropwise addition w...

Embodiment 3

[0029] Weigh 738kg of deionized water, 166.8kg of acrylamide monomer (AM), 16kg of dimethyl diallyl ammonium chloride (DMDAAC), 7kg of acrylic acid, 8kg of butylated methylolacrylamide monomer, 1.5kg of poly Ethylene glycol dimethacrylate, a total of 199.3kg of monomers, made into a solution, adjusted the pH value to about 3-5, then added 195g of sodium bisulfite, stirred and dissolved, and passed nitrogen gas for 40 minutes for later use. 20% by weight of the monomer solution is added to the reaction kettle as a kettle material, and the remaining monomer solution is added to the dropping tank 1 as a dropping solution for subsequent use.

[0030] Add 390g of ammonium persulfate into 65kg of water to form a solution, and add it to the dropping tank 2.

[0031] The temperature of the reaction kettle was raised to 35° C., and the solution in the dropping tanks 1 and 2 was started to be added dropwise. It is required to finish dripping in 180min. After the dropwise addition was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com