Oil-in-water emulsion cosmetic for eyelashes

An oil-in-water, cosmetic technology, used in cosmetics, cosmetics, cosmetic preparations, etc., can solve problems such as curling effect and thick feeling, caking, whitening, etc., and achieve full storage stability and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14 and comparative example 1~7

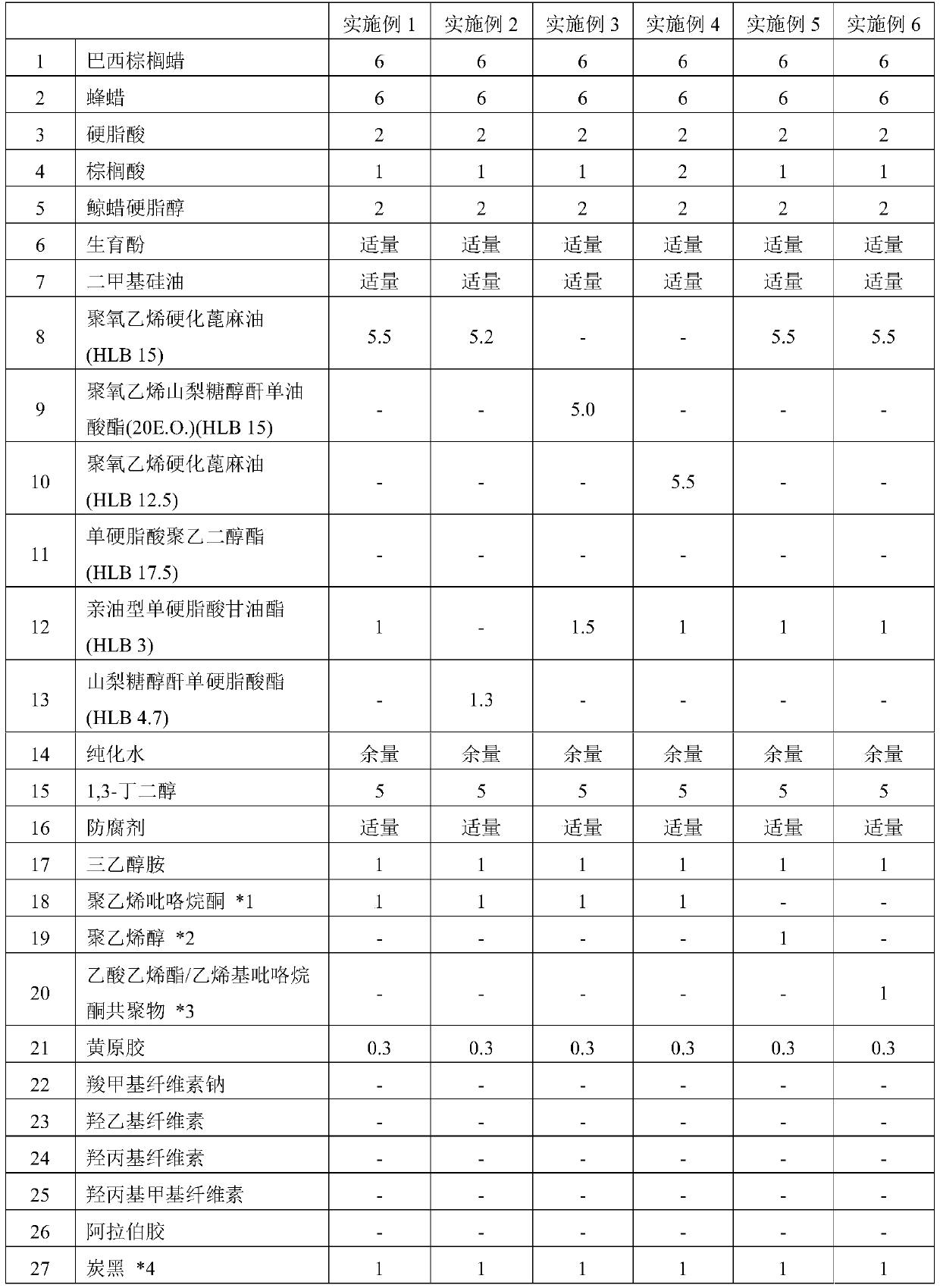

[0106] The oil-in-water cosmetics for eyelashes having the compositions shown in Tables 1 to 5 were prepared by the following manufacturing methods, and the above-mentioned evaluations were performed. The results are shown in Tables 1-5 together.

[0107]

[0108] Components 1 to 13 were mixed, dissolved and homogenized by heating to 90° C., and this was used as an oil phase. Next, components 14 to 28, which were heated and dissolved at 90° C., were added to the oil phase and emulsified. After cooling the emulsion, component 29 was added and stirred. This was filled in a container to obtain an oil-in-water mascara.

[0109] [Table 1]

[0110]

[0111]

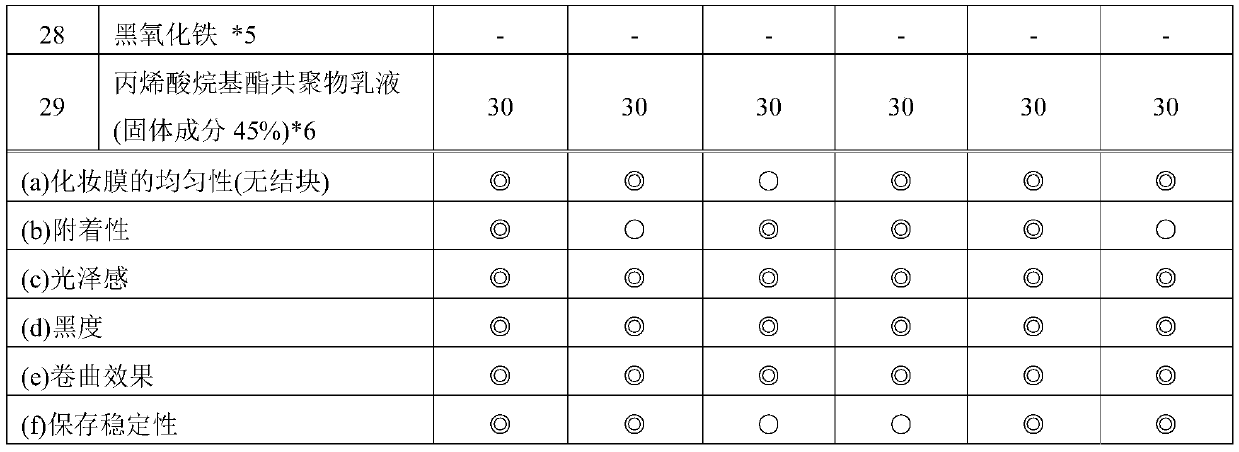

[0112] [Table 2]

[0113]

[0114]

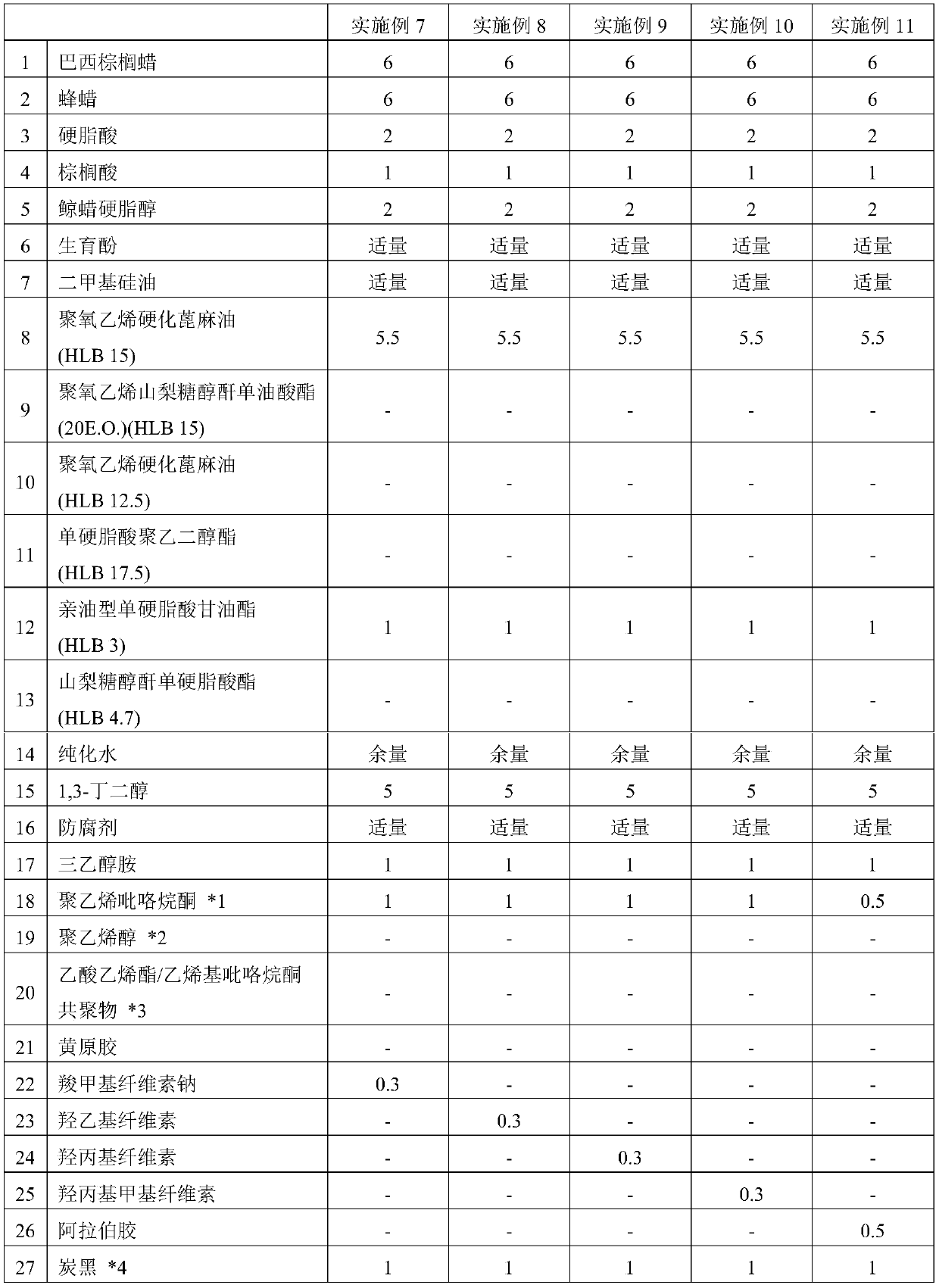

[0115] [table 3]

[0116]

[0117]

[0118] [Table 4]

[0119]

[0120]

[0121] [table 5]

[0122]

[0123]

[0124] In Tables 1 to 5, the details of *1 to *6 are as follows.

[0125] *1: PVP K-90 (manufactured by ISP Japan Ltd., product name)

[012...

Embodiment 15

[0132] (Example 15: mascara (containing fiber))

[0133]

[0134]

[0135] *The details of 1, 4, and 6 are the same as above.

[0136]

[0137] Components (1) to (10) were heated to about 90° C., mixed uniformly, and used as an oil phase. Next, components (11) to (16) heated to about 90° C. were added to the obtained oil phase and emulsified. After cooling the emulsion, component (17) was added and stirred. This was filled in a container to obtain an oil-in-water mascara (containing fibers).

[0138]

[0139] The obtained mascara (containing fibers) was evaluated in the same way as above. As a result, (a) the uniformity of the makeup film (no lumps), (b) adhesion, (c) gloss, (d) All the evaluation items of blackness, (e) curling effect, and (f) storage stability were evaluated as "⊚".

Embodiment 16

[0140] (Example 16: eyelash primer)

[0141]

[0142]

[0143] *The details of 2, 4, and 6 are the same as above.

[0144]

[0145] Components (1) to (11) were heated to about 90° C. and uniformly mixed to obtain an oil phase. Next, components (12) to (17) heated to about 90° C. were added to the obtained oil phase and emulsified. After cooling the emulsion, component (18) was added and stirred. Fill it into a container and you get a mascara primer.

[0146] The obtained mascara primer was evaluated in the same way as above. As a result, (a) uniformity of makeup film (no caking), (b) adhesion, (c) luster, (e) curling effect And (f) the evaluation of "⊚" among all the evaluation items of storage stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com