Environment-friendly organosilicone sealant and manufacturing method thereof

A manufacturing method and sealant technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of storage stability that are not mentioned, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

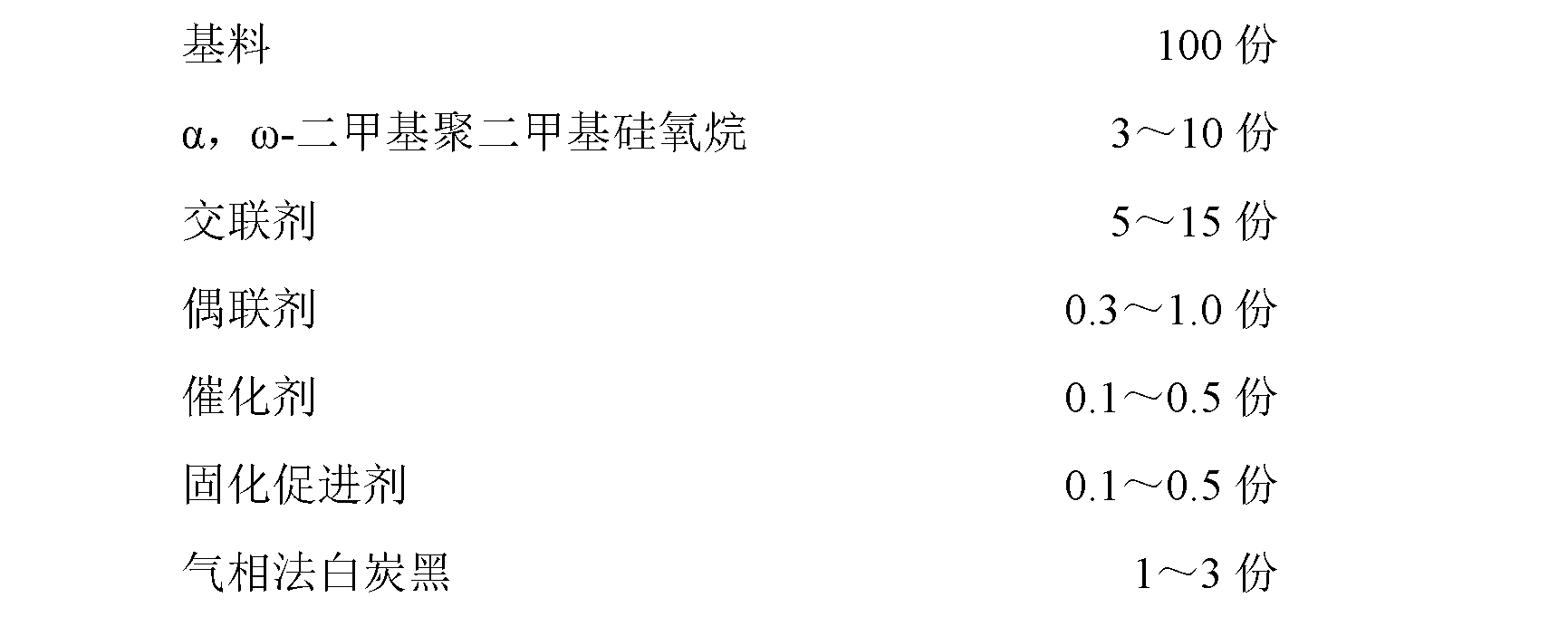

Method used

Image

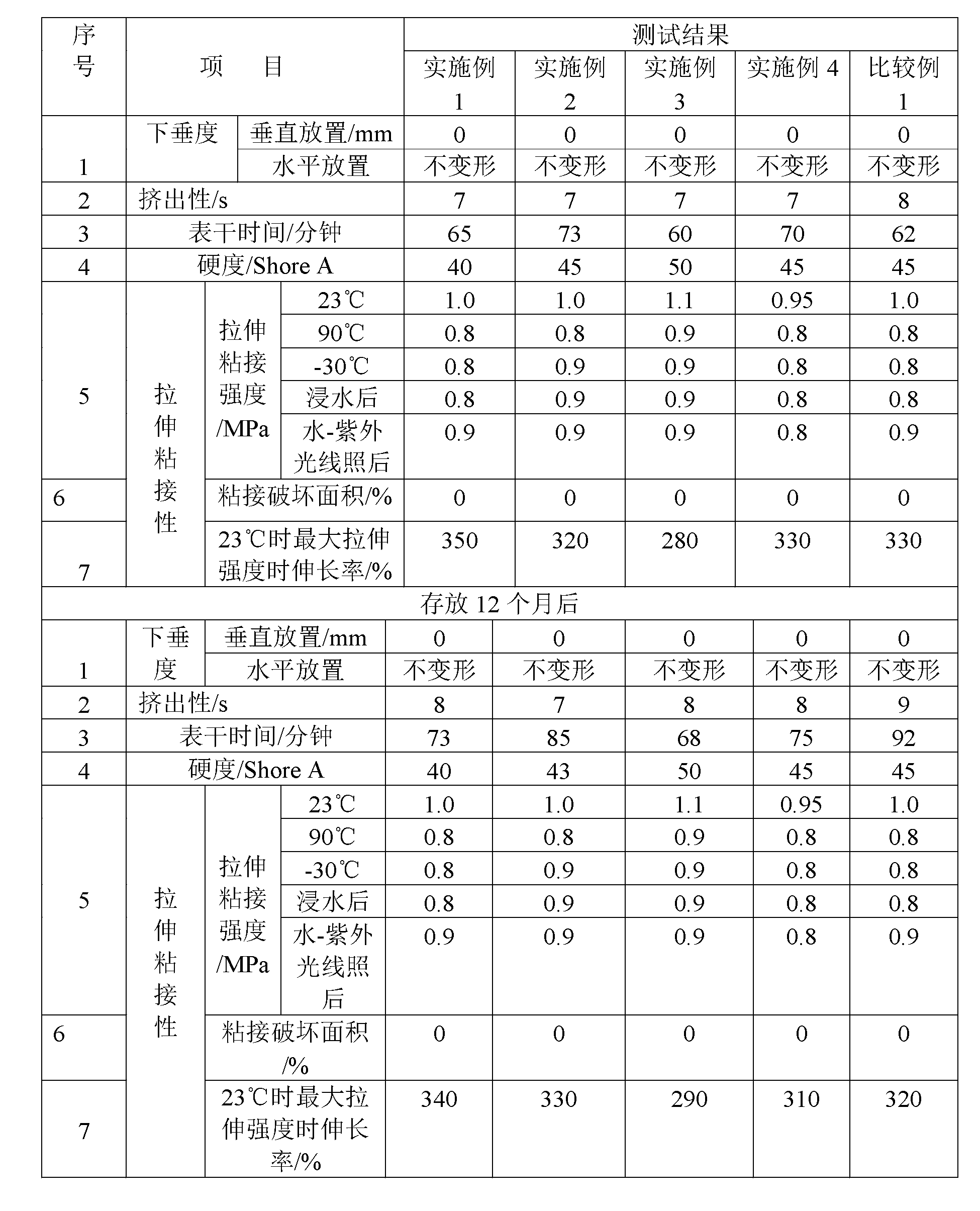

Examples

Embodiment 1

[0029] 100 kg of α, ω-dihydroxypolydimethylsiloxane and 50 kg of filler were dehydrated and blended for 240 minutes in a vacuum kneader at 120° C. and a vacuum degree of 0.099 MPa to obtain a base material. Take 100 parts of base material, 3 parts of α, ω-dimethyl polydimethylsiloxane, and 1 part of tetrabutylketoxime silane and add them into the disperser. The structural formula is 0.5 kg of curing accelerator, vacuumize and stir for 30 minutes under a vacuum degree of 0.06MPa, then add 10 kg of phenyl tributylketoxime silane and 4 kg of vinyl tributylketoxime silane, and continue to mix under a vacuum degree of 0.06MPa After vacuum stirring for 20 minutes, add 0.5 kg of γ-aminopropylmethyldiethoxysilane, 0.5 kg of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, dimethyl dineodecanoate Tin 0.1 kg, vacuumize and stir for 20 minutes under vacuum degree of 0.06MPa, add 3 kg of fumed white carbon black, stir for 3 minutes, continue to vacuumize and stir under vacuum degree of 0.06MP...

Embodiment 2

[0031] 100 kg of α, ω-dihydroxypolydimethylsiloxane and 100 kg of filler were dehydrated and blended for 180 min in a vacuum kneader at 150° C. and a vacuum of 0.08 MPa to obtain a base material. Get 100 kilograms of base materials, α, 5 kilograms of omega-dimethylpolydimethylsiloxane, 2 kilograms of tetrabutylketoxime base silanes, and the structural formula is Add 0.1 kg of curing accelerator to the disperser, vacuumize and stir for 30 minutes at a vacuum of 0.08 MPa, then add 5 kg of phenyltributylketoximosilane, 5 kg of vinyltrimethylisobutylketoximosilane kg, continue vacuuming and stirring for 30 minutes at a vacuum degree of 0.08MPa, then add 0.4 kg of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane, γ-methacryloxypropyltrimethoxy 0.4 kg of base silane, 0.2 kg of bismuth neodecanoate, Bi(C 7 h 15 COO) 3 After 0.1 kg was vacuumed and stirred for 30 minutes at a vacuum of 0.08 MPa, 2 kg of fumed white carbon black was added and stirred for 3 minutes. After shoveling, ...

Embodiment 3

[0033]100 kg of α, ω-dihydroxypolydimethylsiloxane and 120 kg of filler were dehydrated and blended for 200 minutes in a vacuum kneader at 140° C. and a vacuum degree of 0.09 MPa to obtain a base material. Get 100 kilograms of base materials, α, 8 kilograms of omega-dimethylpolydimethylsiloxane, 1 kilogram of tetramethylketoxime base silane, and 1 kilogram of tetramethylisobutylketoxime base silane, and the structural formula is:

[0034] Add 0.2 kg of curing accelerator to the extension machine, vacuumize and stir for 30 minutes at a vacuum degree of 0.09 MPa, then add 4 kg of vinyl trimethoxyisobutyl ketoximino silane, methyl trimethyl isobutyl ketoximino silane 4 kg of silane silane, continue vacuuming and stirring for 30 minutes at a vacuum degree of 0.09 MPa, add 0.3 kg of γ-aminopropyltriethoxysilane, 0.5 kg of zinc neodecanoate, and vacuumize and stir for 20 minutes at a vacuum degree of 0.09 MPa , add 2 kg of fumed white carbon black, stir for 3 minutes, continue vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com