Preparation device and preparation method for silicon ball

A technology for preparing devices and silicon spheres, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of increased processing costs, slow cooling speed and small grain silicon blocks, and secondary pollution of metals, and achieves improved Fluidity, viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

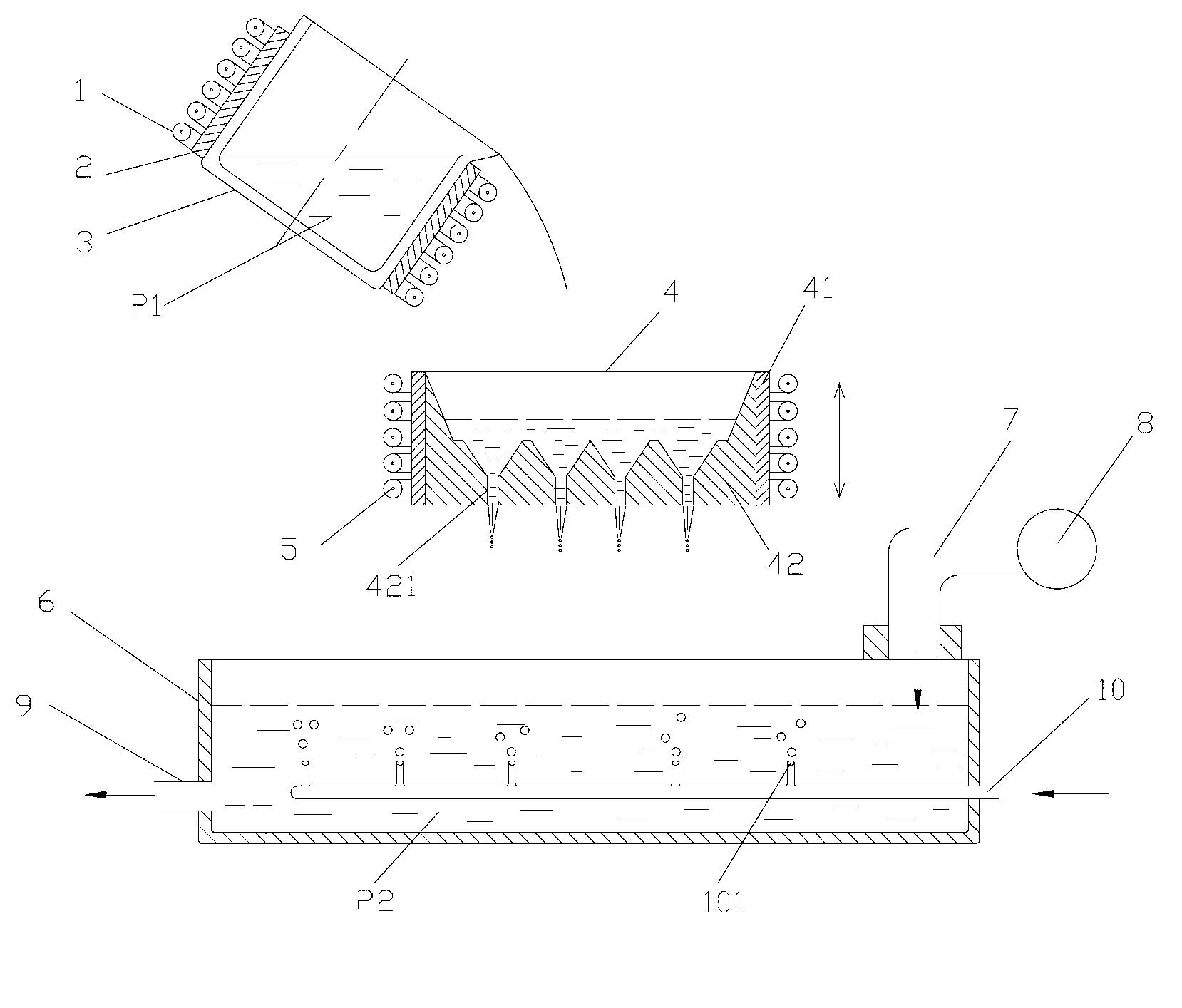

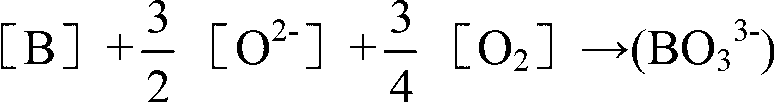

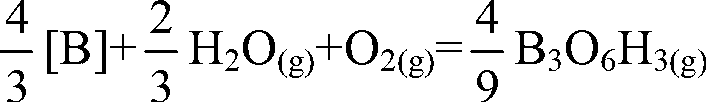

Method used

Image

Examples

Embodiment 1

[0061] Take 10kg of metallurgical grade silicon powder and place it in a graphite crucible with an initial boron content of 15ppmw. Slagging agent: Na 2 CO 3 -SiO 2 -NaF, wherein the mass percentage of each component is: Na 2 CO 3 : 4kg; SiO 2 : 5kg; NaF: 1kg. Start the heating, the power is 50kW, the heating time is 1h, the silicon powder is completely melted, and the temperature of the silicon liquid is 1700°C.

[0062] Add slagging agent to the silicon liquid, the power is 50kW when adding slag, and the time for slag adding is 10min; the power for slag melting is 55kW, and the time for slag melting is 10min; After the slagging is completed, turn off the power and let it stand for 15 minutes; rotate the furnace body and dump the upper layer of slagging agent. The shunt starts heating, the power is 25kW, the temperature of the shunt is kept at 1600°C, and the silicon liquid is poured into the shunt.

[0063] When the height between the outlet of the diverter and the l...

Embodiment 2

[0067] A 10kg metallurgical grade silicon block was taken and placed in a graphite crucible, and the initial boron content of the silicon block was 15ppmw.

[0068] Take 20kg of evenly mixed slag agent and place it in the feeding bin on the top of the crucible. Slagging agent: Na 2 CO 3 -SiO 2 -NaF, wherein the mass percentage of each component is: Na 2 CO 3 : 10kg; SiO2 2 : 8kg; NaF: 2kg. Start heating, the power is 60kW, the heating time is 1.5h, the silicon block is completely melted, and the temperature of the silicon liquid is 1750°C at this time.

[0069] Add slagging agent to the silicon liquid, the power is 50kW when adding slag, and the time for slag adding is 15min; the power for slag melting is 55kW, and the time for slag melting is 15min; After the slagging is completed, turn off the power and let it stand for 20 minutes; rotate the furnace body and dump the upper layer of slagging agent. The shunt starts heating, the power is 25kW, the temperature of the sh...

Embodiment 3

[0072] Take 10 kg of metallurgical grade silicon powder and place it in a graphite crucible, the initial boron content of the silicon powder is 15 ppmw.

[0073] Take 30kg of evenly mixed slag agent and place it in the feeding bin on the top of the crucible. Slagging agent: Na 2 CO 3 -SiO 2 -NaF, wherein the mass percentage of each component is: Na 2 CO 3 : 18kg; SiO2 2 : 9kg; NaF: 3kg. Start the heating, the power is 50kW, the heating time is 2h, the silicon powder is completely melted, and the temperature of the silicon liquid is 1700°C.

[0074] Add slagging agent to the silicon liquid, the power is 50kW when adding slag, and the time for slag adding is 20min; the power for slag melting is 55kW, and the time for slag melting is 20min; After the slagging is completed, turn off the power and let it stand for 20 minutes; rotate the furnace body and dump the upper layer of slagging agent. The shunt starts heating, the power is 25kW, the temperature of the shunt is kept a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com