Biodegradable and medical tricalcium phosphate/gamma-polyglutamic acid composite and preparation method thereof

A technology of tricalcium phosphate and polyglutamic acid, applied in the field of biomedicine, can solve the problems of difficult control of degradation rate, limited depth of bone ingrowth, and long time, etc., and achieve the effect of uniform distribution of tricalcium phosphate and appropriate pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

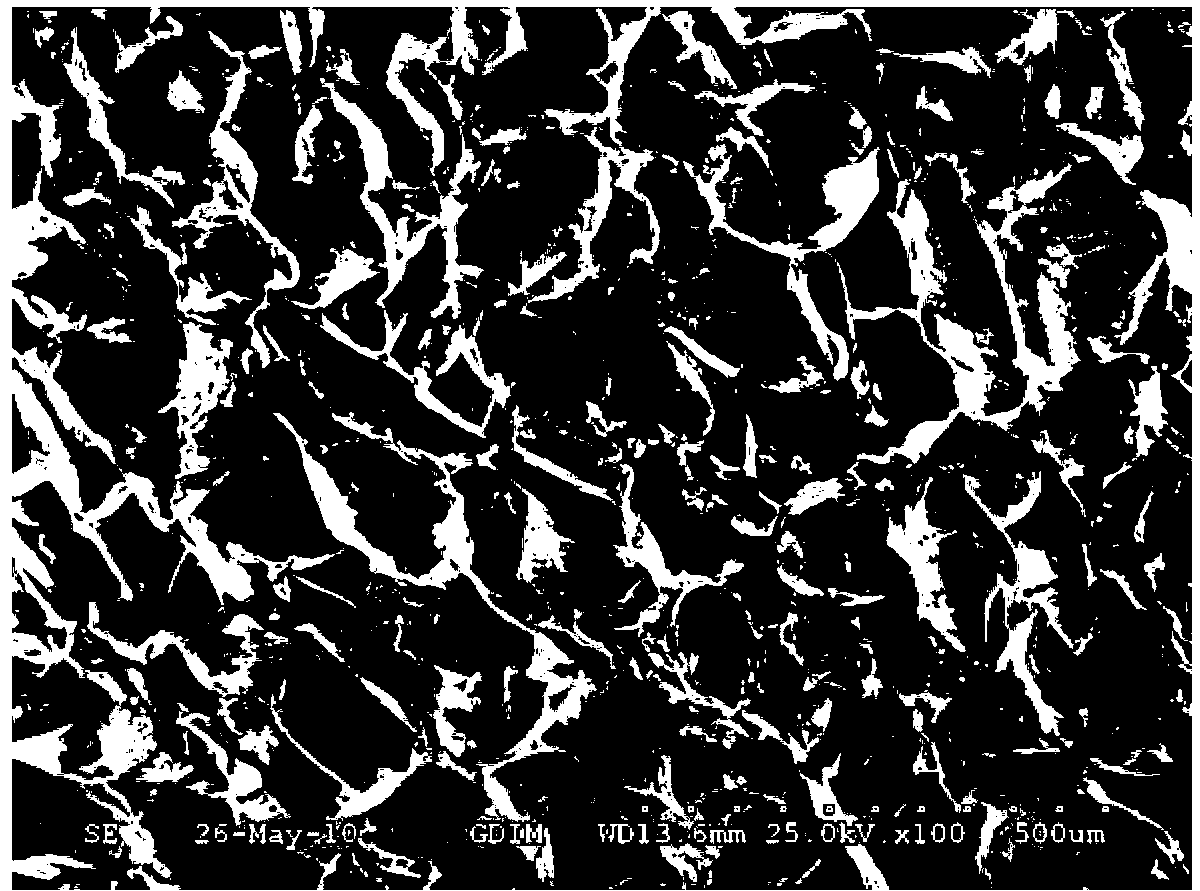

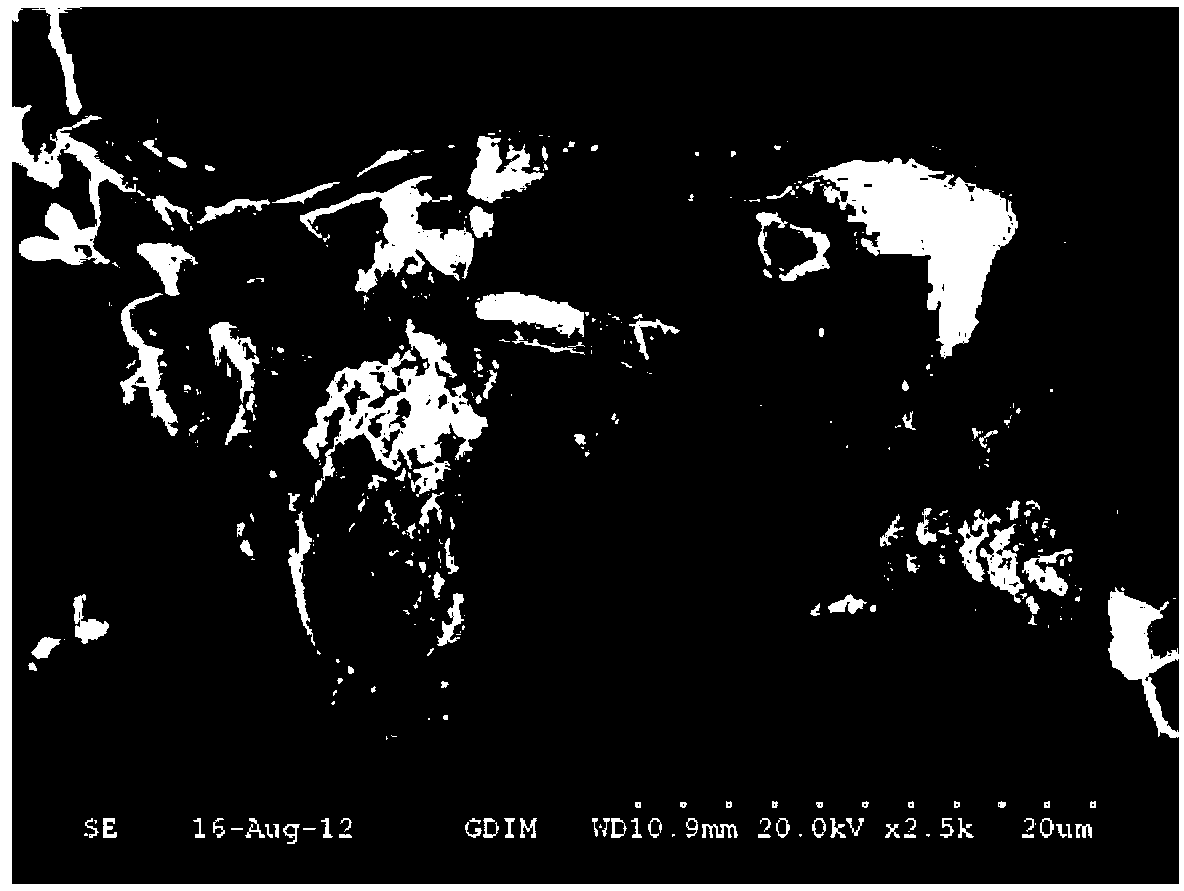

Image

Examples

Embodiment 1

[0028] Dissolve 1 g of γ-polyglutamic acid in 50 mL of deionized water, and stir until a transparent viscous emulsion is formed to obtain a γ-polyglutamic acid solution, which is set aside. Add 5g of β-tricalcium phosphate into 10ml of 0.1mol / L dilute hydrochloric acid, stir for 0.5h until completely dissolved, then treat it with ultrasonic waves (ultrasonic frequency: 40KHZ, 10min), and then use sodium hydroxide solution to bring the pH value to 4.0 , and set the volume to 50mL to obtain a β-tricalcium phosphate solution. Add gamma-polyglutamic acid solution into the treated beta-tricalcium phosphate solution, stir and mix evenly to obtain gamma-polyglutamic acid / beta-tricalcium phosphate solution. In the γ-polyglutamic acid / β-tricalcium phosphate solution, add 10ml of an aqueous solution containing 0.05g of allyl glycidyl ether dropwise under stirring, and stir the mixture at room temperature for 1 hour, and a white colloidal suspended substance appears in the solution , st...

Embodiment 2

[0031]Dissolve 5 g of γ-polyglutamic acid in 50 mL of deionized water, and stir until a transparent viscous emulsion is formed to obtain a γ-polyglutamic acid solution, which is set aside. Add 1g of β-tricalcium phosphate into 10ml of 1.0mol / L dilute hydrochloric acid, stir for 1h until completely dissolved, then treat it with ultrasonic waves (ultrasonic frequency: 40KHZ, 10min), adjust the pH value to 5.0 with ammonia solution, and dilute to 40mL , to obtain β-tricalcium phosphate solution. Add gamma-polyglutamic acid solution into the treated beta-tricalcium phosphate solution, stir and mix evenly to obtain gamma-polyglutamic acid / beta-tricalcium phosphate solution. In the γ-polyglutamic acid / β-tricalcium phosphate solution, add dropwise 10ml of an aqueous solution containing 0.2g of glycerol triglycidyl ether, and stir the mixture at room temperature for 1 hour. A white colloidal suspended substance appears in the solution. Stop stirring. After all the colloidal substance...

Embodiment 3

[0034] Dissolve 2.5g of γ-polyglutamic acid in 50mL of deionized water, and stir until a transparent viscous emulsion is formed to obtain a γ-polyglutamic acid solution, which is set aside. Add 10g of β-tricalcium phosphate to 20mL of 1.0mol / L dilute hydrochloric acid, stir for 0.5h until completely dissolved, then treat it with ultrasonic waves (ultrasonic frequency: 40KHZ, 10min), then adjust the pH value to 6.0 with sodium hydroxide, and set Make up to 40mL to obtain β-tricalcium phosphate solution. Add gamma-polyglutamic acid solution into the treated beta-tricalcium phosphate solution, stir and mix evenly to obtain gamma-polyglutamic acid / beta-tricalcium phosphate solution. In the γ-polyglutamic acid / β-tricalcium phosphate solution, add dropwise 10ml aqueous solution containing 1.0g polyethylene oxide sorbitol polyglycidyl ether under stirring, and stir the mixture at room temperature for 1h, and the solution appears White colloidal suspended substance, stop stirring, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com