Production method of normal-temperature normal-pressure cationic dyeable fine-denier hollow polyester staple fiber

A cationic polyester, production method technology, applied in fiber processing, hollow filament manufacturing, fiber chemical characteristics, etc., can solve problems such as unseen production methods, and achieve high closing success rate, excellent breaking strength, and reduced modulus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

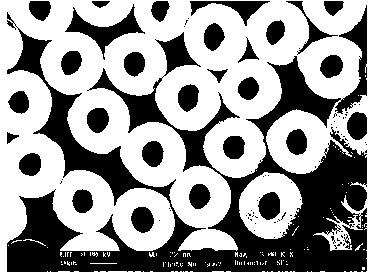

[0026] The present invention adopts specific fine-denier hollow special-purpose spinneret, and through the optimization and adjustment of the production process on the conventional slicing and spinning polyester staple fiber production line, the normal temperature and pressure cationic dyeable fine-denier hollow polyester with specifications of 1.3dtex to 2.5dtex is produced Short fibers have achieved the similar performance of cashmere products and filled the blank at home and abroad.

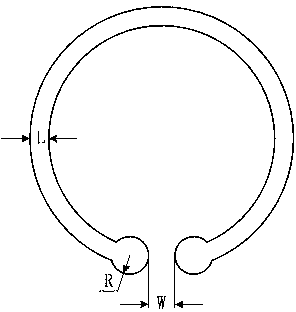

[0027] First of all, the present invention adopts an innovatively designed spinneret, and the spinneret hole is in the shape of a single-opening "C" ring, such as figure 1 As shown, while effectively improving the closing success rate of the cross-section of the fiber, the fiber is guaranteed to have a high degree of hollowness.

[0028] The invention achieves the purpose of stably producing normal temperature and pressure cationic dyeable fine denier hollow polyester staple fibers with specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slit width | aaaaa | aaaaa |

| Opening | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com