Process for recovering inhibited pyrite and pyrrhotite by utilizing two-step method

A technology of pyrite and two-step method, which is applied in the direction of solid separation and flotation, which can solve the problems of difficulty in product sales, impact on economic benefits of mines, differences in ingredients for acid production, and differences in roasting temperature requirements, so as to reduce environmental pollution and occupancy Land issues, improving mine and social and economic benefits, and improving the effect of comprehensive recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

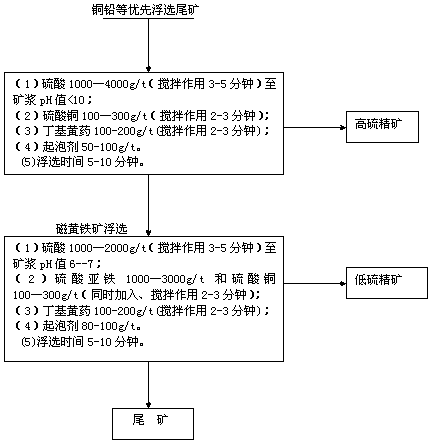

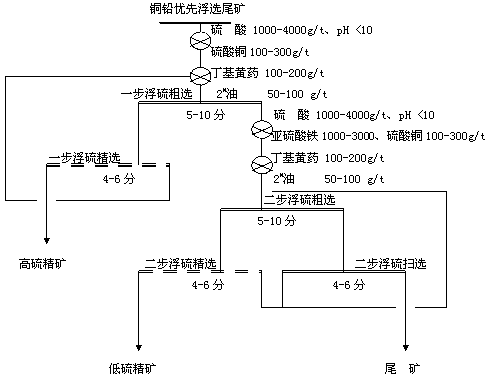

[0022] Embodiment 1: add figure 2 shown; including the following steps:

[0023] (1) The copper flotation tailings flow into the chemical mixing tank 1, and the concentrated (dilute) sulfuric acid is pumped into the mixing tank 1 by the chemical pump according to the requirements, and the tailings (pH value <10) fully reacted with sulfuric acid flow into the chemical mixing tank 2, Add copper sulfate to the chemical mixing tank 2, and the tailings that have fully reacted with copper sulfate flow into the flotation machine 1 (butyl xanthate and foaming agent are added at the front entrance of the flotation machine), flotation for 5-10 minutes, and the foam floats (High-sulfur concentrate) is scraped off by the scraper of the flotation machine. The amount of sulfuric acid depends on the pH of the copper flotation tailings slurry. The key point is that the pH of the slurry should be adjusted to <10; High and low are determined.

[0024] (2) The high-sulfur concentrate flotati...

Embodiment 2

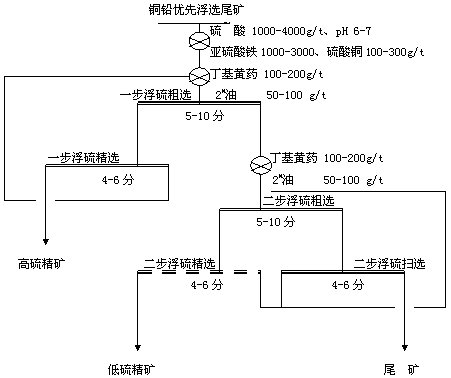

[0026] Embodiment 2: as image 3 shown, including the following steps:

[0027] (1) The copper flotation tailings flow into the chemical mixing tank 1, and the concentrated (dilute) sulfuric acid is pumped into the mixing tank 1 by the chemical pump according to the required amount, and the tailings (pH value 6--7) fully reacted with sulfuric acid flow into the chemical mixing tank 2. Add ferrous sulfate and copper sulfate to the chemical mixing tank 2, and the tailings that have fully reacted with copper sulfate flow into the flotation machine 1 (butyl xanthate and foaming agent are added at the front entrance of the flotation machine), pyrite Good buoyancy, fast flotation speed, the first 5-10 minutes, the floating foam is high sulfur concentrate. After 10-15 minutes, the floating foam is low-sulfur concentrate, and high-sulfur concentrate and low-sulfur concentrate are obtained respectively. The key point is to adjust the pH value of the pulp to 6-7; the amount of butyl x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com