Supported composite sulfur phosphide hydrotreatment catalyst, preparation and applications thereof

A hydrotreating and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problem that the improvement of oil hydrodesulfurization activity is not obvious, and achieve low cost and operation process. Simple and good hydrodesulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

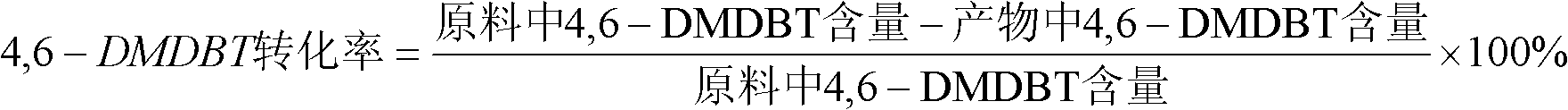

Method used

Image

Examples

Embodiment 1

[0027] Weigh 1000g of industrial pseudo-boehmite, extrude it into a clover shape with a circumscribed circle diameter of 1.8mm on an extruder, dry at 120°C for 6 hours, and calcinate at 550°C for 4 hours to obtain catalyst carrier S1.

[0028] Using S1 as the carrier, weigh 9g of nickel nitrate, 5.2g of ammonium phosphomolybdate, 15.4g of ammonium tungstate, 2.3g of ethylenediamine, and 2g of diammonium hydrogen phosphate to prepare a mixed solution, set the volume to 42ml, and impregnate on 50g of carrier S1 4 hours, drying at 120°C, then vulcanization, vulcanization conditions: containing CS 2 2.5% (mass content) straight-run gasoline, pressure: 6MPa; temperature rise program: rise from room temperature to 230°C at a rate of 1°C / h, keep the temperature constant for 8 hours, and then rise to 360°C, constant temperature for 6 hours; hydrogen-oil ratio: 600:1; space velocity: 1.5h -1 . The obtained catalyst is denoted as C1.

Embodiment 2

[0030] Dissolve 9g of nickel nitrate in 100ml of deionized water, add dropwise 2mol / L NaOH solution, stir until all precipitate, filter the above precipitate with suction, and wash the filter cake with deionized water for several times until no 8O is detected. 4 2- and Na + the presence of plasma. The resulting filter cake was placed in 20 ml of deionized water, then stirred and added dropwise with 30 wt% H 3 PO 2 solution until the precipitate is completely dissolved. Then add 3.6g of ammonium molybdate, 15.4g of ammonium tungstate and 8.3g of citric acid into the solution to dissolve, and finally make up 42ml of the solution, impregnate it on 50g of carrier S1 for 4 hours, dry it at 120°C, and then vulcanize it. : with CS 2 2.5% (mass content) straight-run gasoline, pressure: 6MPa; temperature rise program: rise from room temperature to 230°C at a rate of 1°C / h, keep the temperature constant for 8 hours, and then rise to 360°C, constant temperature for 6 hours; hydroge...

Embodiment 3

[0032] The catalyst precursor in Example 2 was vulcanized at an end point temperature of 380° C. to obtain a catalyst, which was denoted as C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com