Method for manufacturing tungsten pipe

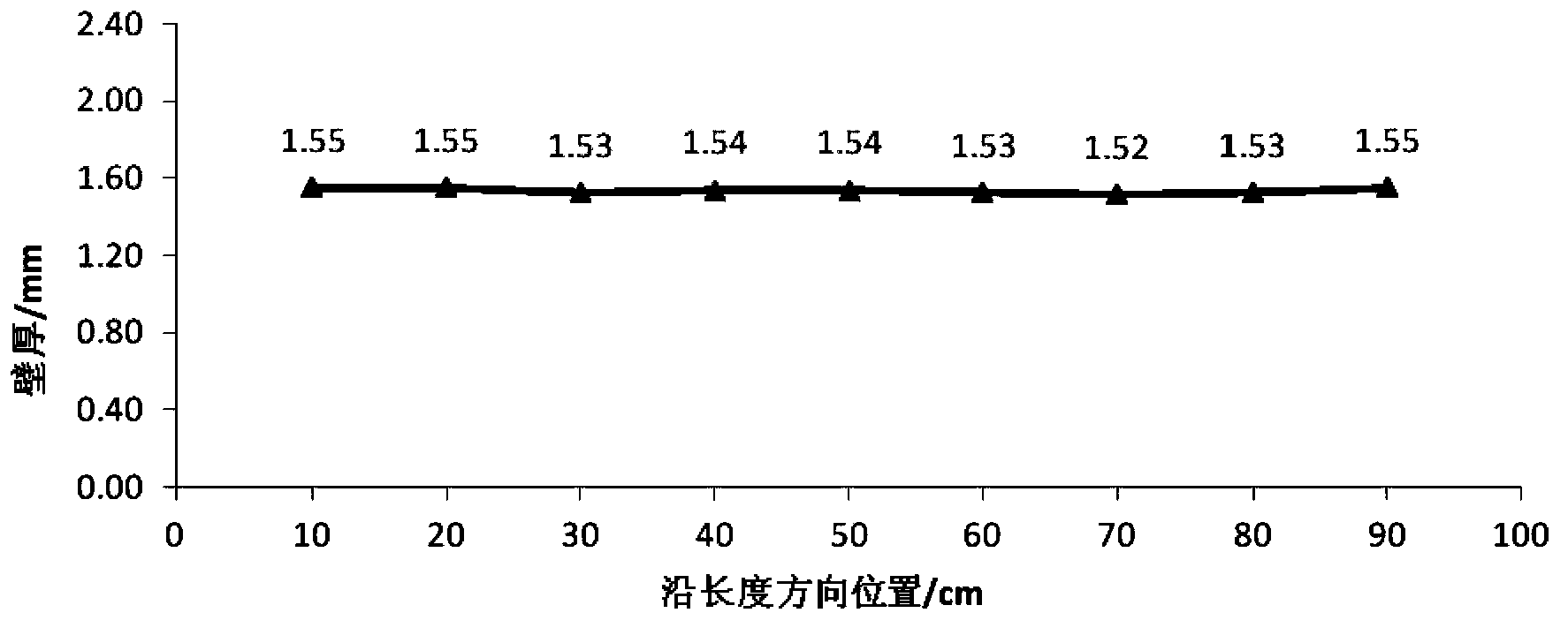

A manufacturing method and substrate technology, applied in the field of tungsten tubes, can solve the problems of uneven wall thickness of tungsten tubes, inability to precisely control the flow of raw material gas, uneven temperature, etc., and achieve high density, high purity, and uniform wall thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

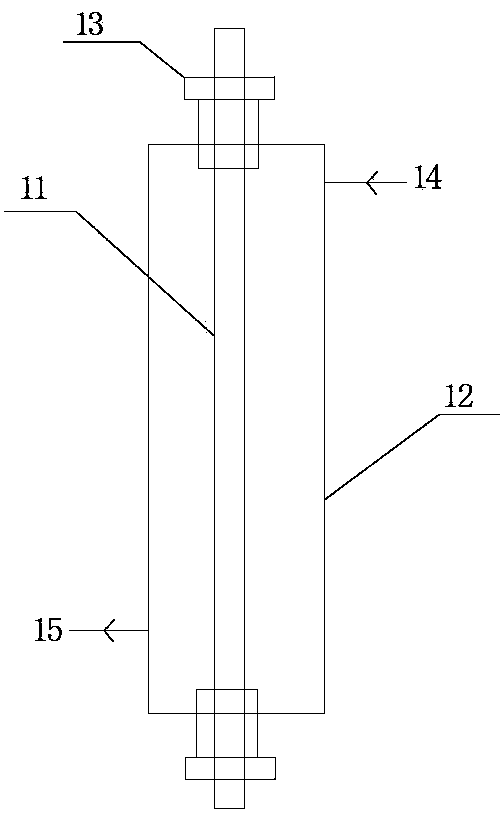

[0018] see Figure 1~3 , first provide a substrate with a smooth surface, stainless steel pipe or copper pipe can be selected, with a diameter of 5-20mm, a wall thickness of 0.5-1mm, and a length figure 2 ). Under the protection of gas, start to energize and heat the substrate and gradually increase the current to 10-40A. The protective gas can be nitrogen or hydrogen, and the flow rate is controlled at 1-5L / min. The present invention uses hydrogen as the protective gas, and the flow rate is 3L / min. min, the substrate current was increased to 30A.

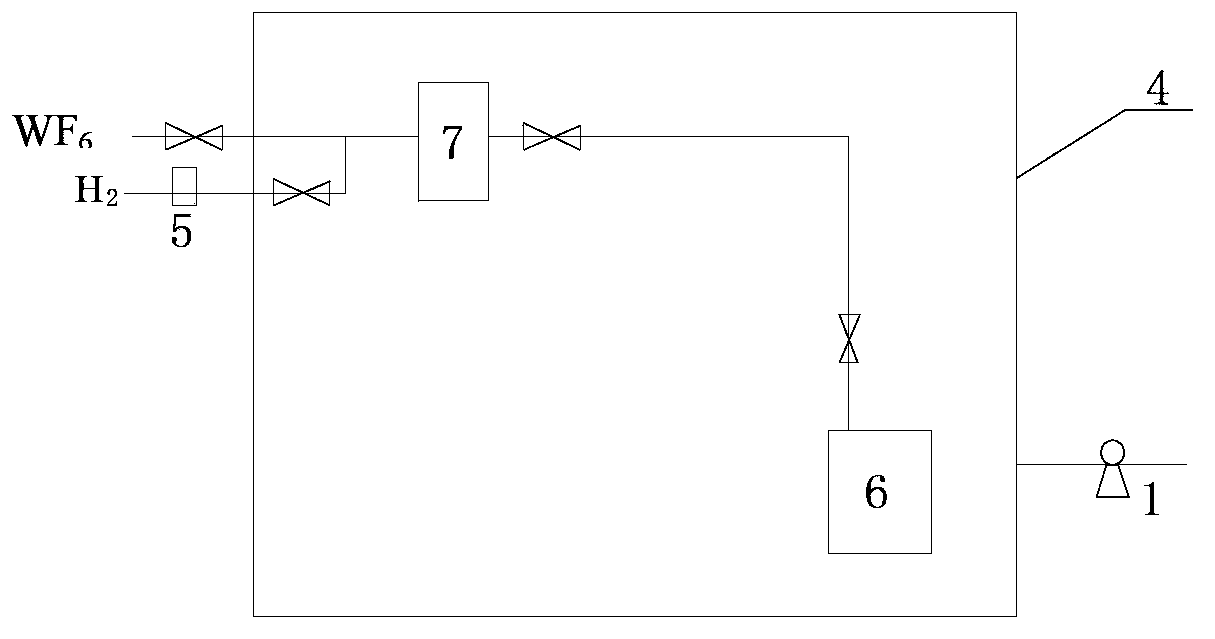

[0019] Then use the constant temperature gas distribution system to feed the reaction gas H 2 , the thermostatic gas distribution system (see figure 1 ) is equipped with raw material bottle 6, incubator 4, hot air blower 1, WF 6 Flow meter 7, H 2 Flow meter 5, temperature can be controlled at 30~50 ℃, and the present invention controls temperature at 40 ℃. The reaction gas is WF with a purity greater than 99.9% 6 and H with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com