Nanoscale efficient heat-insulated wall plate and construction method thereof

A thermal insulation, nano-scale technology, applied in thermal insulation, walls, building components, etc., can solve the problems of non-compliance with green environmental protection, low fire resistance and flame retardant coefficient, poor thermal insulation performance, etc., to reduce logistics, transportation and storage costs. , less consumables, improve the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

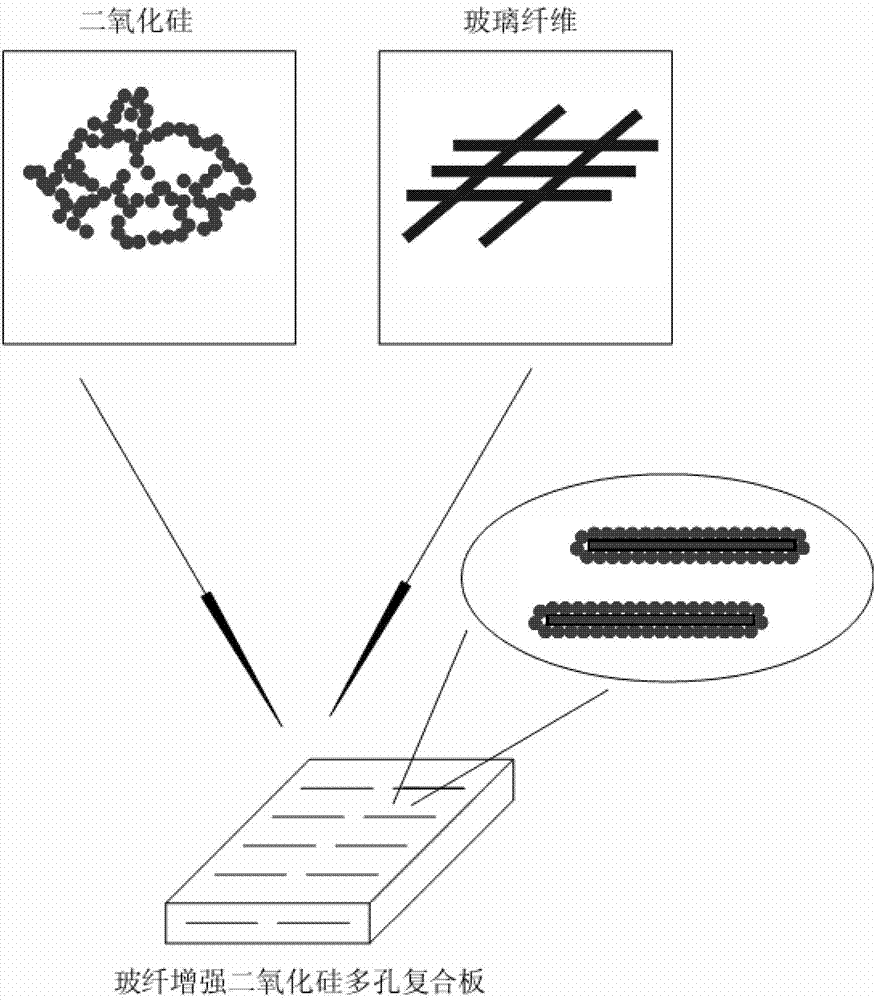

[0028] At room temperature, the fumed silica powder and glass fiber are placed in a vibrator with a mass ratio of 9:1, and after 30 minutes of vibration in the equipment, the surface of the powder particles reaches a mechanically molten state, adsorbed on the well-dispersed On the single fiber, so that the powder fully wraps the glass fiber to form a sandwich structure. Then put the mixture into a square mold with a size of 500mm×500mm, apply a pressure of 0.5MPa, and keep the pressure for 4 hours to make it into shape. A new type of composite wallboard with high efficiency, light weight, heat insulation and fire prevention at the nanoscale can be obtained by opening the mold, such as figure 1 shown.

Embodiment 2

[0030] At room temperature, take 75 parts of fumed silica powder, 15 parts of silica airgel powder, and 10 parts of high-silica fiber and place them in a vibrator, and vibrate in the equipment for 30 minutes to make the surface of the powder particles It reaches a mechanical melting state and is adsorbed on the dispersed single fiber, so that the powder fully wraps the high-silica fiber to form a sandwich structure. Then put the mixture into a square mold with a size of 500mm×500mm, apply a pressure of 1MPa, and keep the pressure for 4 hours to make it into shape. A new type of composite wallboard with high efficiency, light weight, heat insulation and fire prevention at the nanoscale can be obtained by opening the mold.

Embodiment 3

[0032] At room temperature, take 55 parts of fumed silica powder, 35 parts of silica airgel powder, and 10 parts of ceramic fiber in the vibrator, and vibrate in the equipment for 30 minutes to make the surface of the powder particles reach a certain level. It is in a state of mechanical melting and adsorbed on the dispersed single fiber, so that the powder fully wraps the ceramic fiber to form a sandwich structure. Then put the mixture into a square mold with a size of 500mm×500mm, apply a pressure of 2MPa, and keep the pressure for 4 hours to make it shaped. A new type of composite wallboard with high efficiency, light weight, heat insulation and fire prevention at the nanoscale can be obtained by opening the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com