Rapid synthesis method of indium phosphide polycrystalline material and multi-tubular quartz phosphorus bubble thereof

A technology for polycrystalline materials and synthesis methods, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth, etc., can solve the problems of impurity pollution, uneven melt ratio, long synthesis time, etc. The effect of increased area, increased contact area, and high purity of crystal synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Rapid synthesis method of indium phosphide polycrystalline material Synthesize 3.0kg near-stoichiometric InP polycrystalline material, the specific operation steps are:

[0040] In the first step, in order to remove the contamination of raw materials by packaging and other factors, the surface of indium is lightly etched with MOS grade dilute hydrochloric acid, and then boiled and cleaned with deionized water several times to remove oxides and residual impurities on the surface of indium to ensure The high-purity indium used in the experiment has a purity of 6N, and the surface is free of dust and other impurities. The cleaned indium is baked in a vacuum oven for about 30 minutes and set aside;

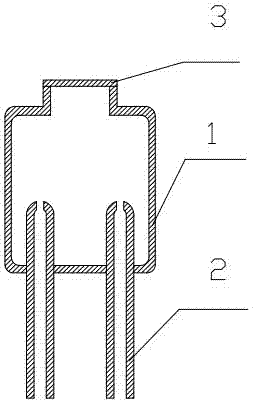

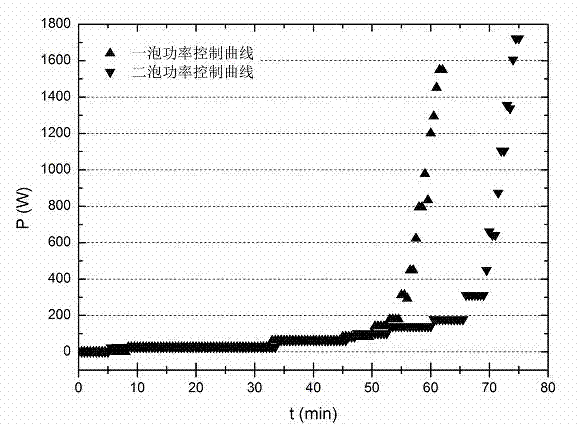

[0041] In the second step, the double-tube quartz phosphorus bubbles containing 6N phosphorus are loaded into the phosphorus source furnace, and two phosphorus bubbles are used for synthesis. The phosphorus source furnace is wound with molybdenum wire and is in the shape of a qu...

Embodiment 2

[0054] Rapid synthesis method of indium phosphide polycrystalline material Synthesize 3.0kg phosphorus-rich InP polycrystalline material, the specific operation steps are:

[0055] In the first step, in order to remove the contamination of raw materials by packaging and other factors, the surface of indium is lightly etched with MOS grade dilute hydrochloric acid, and then boiled and cleaned with deionized water several times to remove oxides and residual impurities on the surface of indium to ensure The high-purity indium used in the experiment reaches 6N purity, and the surface is free of dust and other impurities. The cleaned indium is baked in a vacuum oven for about 30 minutes, and set aside.

[0056] In the second step, the double-tube quartz phosphorus bubbles containing 6N phosphorus are loaded into the phosphorus source furnace, and two phosphorus bubbles are used for synthesis. The phosphorus source furnace is wound with molybdenum wire and is in the shape of a quart...

Embodiment 3

[0067] Rapid synthesis method of indium phosphide polycrystalline material Synthesize 3.0kg near-stoichiometric InP polycrystalline material, the specific operation steps are:

[0068] In the first step, in order to remove the contamination of raw materials by packaging and other factors, the surface of indium is lightly etched with MOS grade dilute hydrochloric acid, and then boiled and cleaned with deionized water several times to remove oxides and residual impurities on the surface of indium to ensure The high-purity indium used in the experiment has a purity of 6N, and the surface is free of dust and other impurities. The cleaned indium is baked in a vacuum oven for about 30 minutes and set aside;

[0069] In the second step, the double-tube quartz phosphorus bubbles containing 6N phosphorus are loaded into the phosphorus source furnace, and two phosphorus bubbles are used for synthesis. The phosphorus source furnace is wound with molybdenum wire and is in the shape of a qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com