Environmental long-term pre-treatment process for surface anodization of aluminum alloy

An aluminum alloy surface and anodic oxidation technology, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of large environmental pollution of light-emitting liquid, affecting the health of operators, corrosion of aluminum substrate, etc., and achieves small damage to the substrate , the reaction is uniform and moderate, and the effect of reducing the loss of aluminum materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

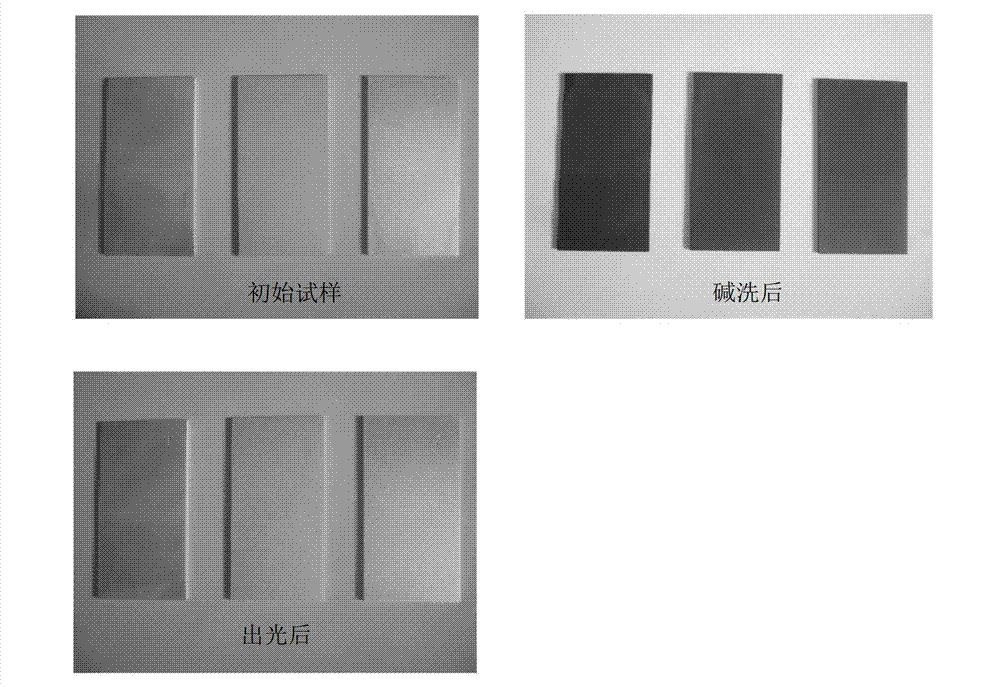

Embodiment 1

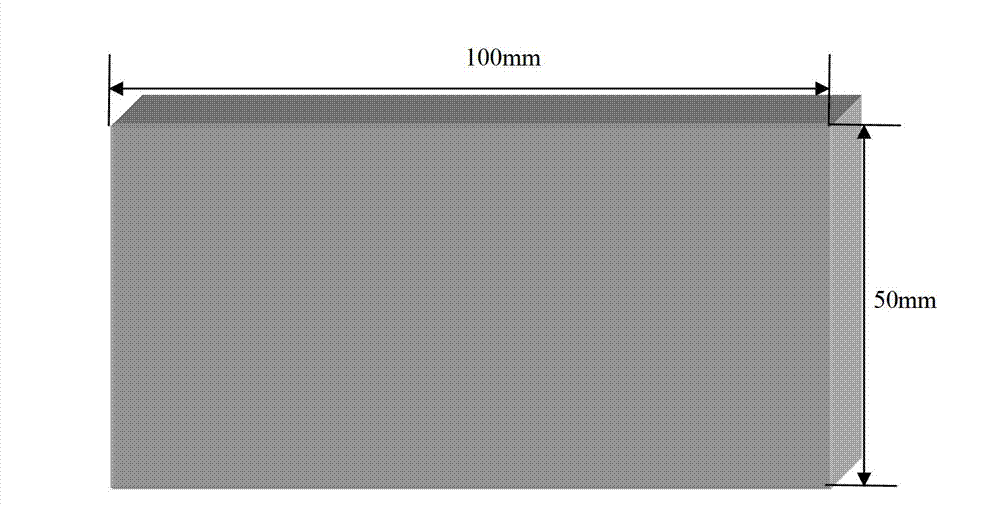

[0025] An environmentally friendly pretreatment process for anodizing the surface of aluminum alloys, including the following steps:

[0026] (1) Alkali etching

[0027] The composition of bath solution is: NaOH50g L -1 , alkali etching agent 70g L -1 , the balance of water; working temperature: 50 ℃, working time 2 minutes.

[0028] Alkaline etching agents include: Na 3 PO 4 20gL -1 , Na 2 CO 3 10gL -1 , sodium gluconate 10g L -1 , sodium benzoate 1gL -1 , sodium dodecylsulfonate 0.1g L -1 , the balance of water.

[0029] (2) hot water wash

[0030] Working temperature: 50°C.

[0031] (3) Wash in cold water

[0032] Working temperature: 20°C.

[0033] (4) light

[0034] The composition of the bath solution is: H 2 SO 4 100gL -1 , sodium molybdate 60g L -1 , the balance of water. Working temperature: 25°C, working time 3 minutes.

[0035] (5) Wash in cold water

[0036] Working temperature: 25°C.

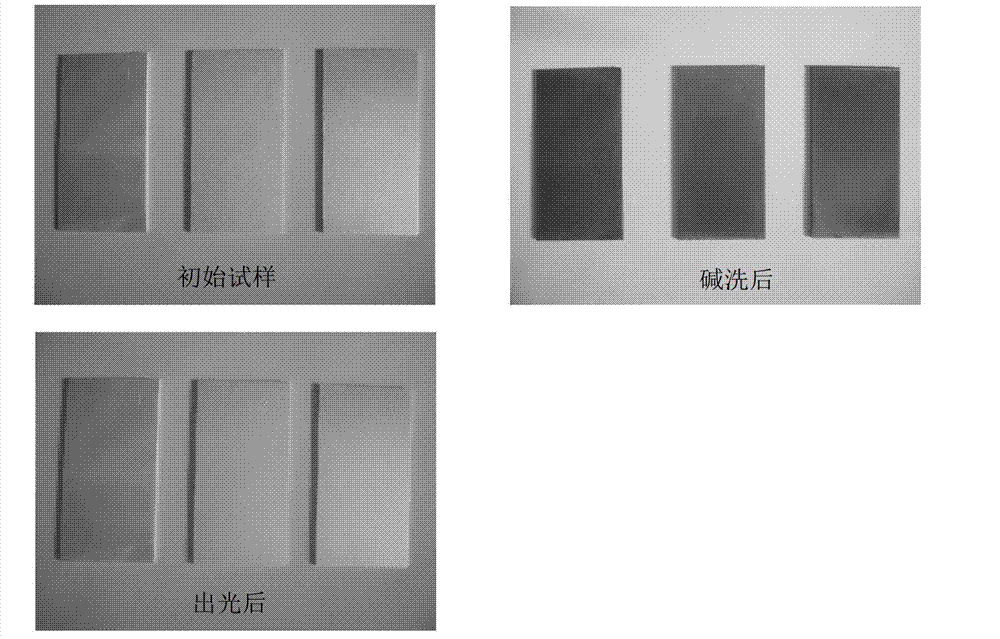

Embodiment 2

[0038] An environmentally friendly pretreatment process for anodizing the surface of aluminum alloys, including the following steps:

[0039] (1) Alkali etching

[0040] The composition of bath liquid is: NaOH75g L -1 , alkali etching agent 80g L -1 , the balance of water; working temperature: 30 ℃, working time 2 minutes.

[0041] Alkaline etching agents include: Na 3 PO 4 25gL -1 , Na 2 CO 3 15gL -1 , sodium gluconate 15g L -1 , sodium benzoate 2g L -1 , sodium dodecylsulfonate 0.3g L -1 , the balance of water.

[0042] (2) hot water wash

[0043] Working temperature: 50°C.

[0044] (3) Wash in cold water

[0045] Working temperature: 20°C.

[0046] (4) light

[0047] The composition of the bath solution is: H 2 SO 4 85gL -1 , sodium molybdate 50g L -1 , the balance of water. Working temperature: 20°C, working time 3 minutes.

[0048] (5) Wash in cold water

[0049] Working temperature: 20°C.

Embodiment 3

[0051] An environmentally friendly pretreatment process for anodizing the surface of aluminum alloys, including the following steps:

[0052] (1) Alkali etching

[0053] The composition of bath solution is: NaOH100g L -1 , alkaline etchant 90g L -1 , the balance of water; working temperature: 10 ℃, working time 3 minutes.

[0054] Alkaline etching agents include: Na 3 PO 4 30gL -1 , Na 2 CO 3 20gL -1 , sodium gluconate 20g L -1 , sodium benzoate 2g L -1 , sodium dodecyl sulfate 0.5g L -1 , the balance of water.

[0055] (2) hot water wash

[0056] Working temperature: 50°C.

[0057](3) Wash in cold water

[0058] Working temperature: 20°C.

[0059] (4) light

[0060] The composition of the bath solution is: H 2 SO 4 70gL -1 , sodium molybdate 40g L -1 , the balance of water. Working temperature: 30°C, working time 3 minutes.

[0061] (5) Wash in cold water

[0062] Working temperature: 20°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com