Halogen-free flame-retardant polypropylene material and preparation method thereof

A flame-retardant polypropylene and polypropylene resin technology, applied in the field of polymer materials and their preparation, can solve the problems of easy occurrence of molten droplets, casting fire, easy combustion, aggravated flame propagation, etc., and achieves good industrial application value and is easy to use. Operation, no effect of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

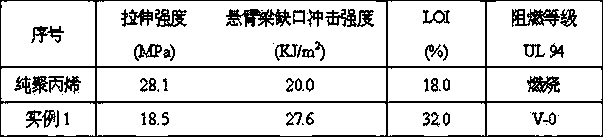

Embodiment 1

[0020] Weigh 100 parts of magnesium hydroxide, 180 parts of aluminum hydroxide, 30 parts of zinc borate, 15 parts of 3-hydroxyphenylphosphorylpropionic acid, 30 parts of ammonium polyphosphate, 10 parts of melamine cyanurate, 6 parts of starch, and 5 parts of talcum powder 3 parts, 3 parts of hindered phenol (AO60) were put into a high-speed mixer and mixed for 5 minutes, then added 180 parts of polypropylene resin, 30 parts of toughening agent POE, 15 parts of compatibilizer POE-g-MAH, 3 parts of lubricant, anti-ultraviolet 2.5 parts of the agent, mixed at high speed for 20 minutes, discharged, extruded and granulated in a twin-screw extruder, and dried at 100°C for 5 hours to obtain a halogen-free flame-retardant polypropylene composite material.

[0021] The dried pellets were injection-molded with an injection molding machine to prepare test samples, and tested for vertical combustion (UL 94), limiting oxygen index (LOI), tensile properties, and impact properties. The test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com