Polytetrafluoroethylene hollow fiber micro-porous film and preparation method thereof

A polytetrafluoroethylene, porous membrane technology, used in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of high efficiency, high mechanical strength and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

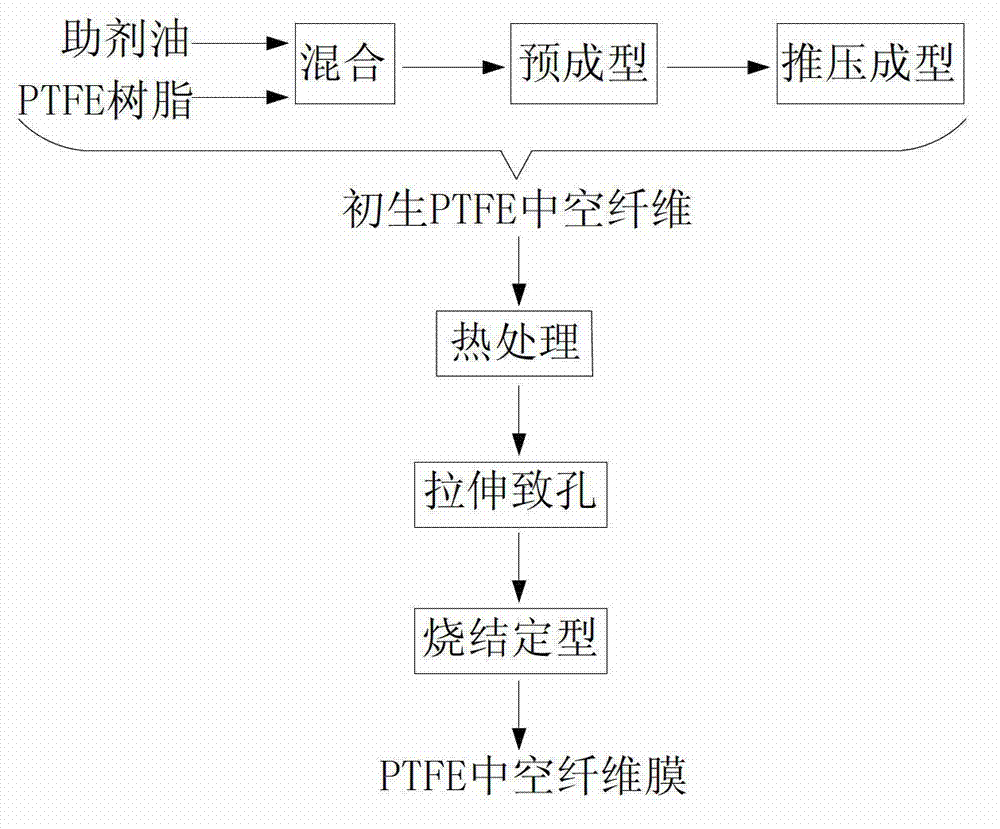

[0040] The preparation steps of the nascent PTFE hollow fiber include mixing PTFE resin and auxiliary oil, preforming compacts and pushing molding to prepare the nascent PTFE hollow fiber.

[0041] Select PTFE dispersion resin with a molecular weight of 1 million to 5 million, a compression ratio of 300 times to 3000 times, and a crystallinity greater than 98%; the PTFE dispersion resin can be either a PTFE resin or a blend of two resins in proportion; when a When a kind of PTFE resin is raw material, preferred molecular weight 2,000,000-4,000,000. This is because, when the molecular weight is less than 2 million, stretching is easy to form holes, but the primary PTFE hollow fiber is easy to break when stretching, and the size of the micropores formed during the stretching process is not easy to control; when the molecular weight is greater than 4 million, it is difficult to stretch to form holes. .

[0042] Auxiliary oil can adopt the following types among the present invent...

Embodiment 1

[0063] 1000g PTFE dispersion resin (Daikin Company. Polyflon, F-205) was mixed with 200g additive oil (Mobil Company Isopar G). Place the mixture at 30°C for about 24 hours to allow the additive oil to completely penetrate into the PTFE resin; then, fill the mixture into a steel cylinder with a diameter of 50mm and a length of 600mm, and place a core rod with a diameter of 12mm in the center of the steel cylinder. After the cylinder is filled, it is pre-pressed; further, the preform is transferred and placed in the extruder barrel of the push molding equipment, kept at 40°C for 10 minutes, and pushed at a constant speed at 5MPa to obtain an outer diameter of 5mm and a wall thickness of 1.2 mm PTFE blank tube, that is, primary PTFE hollow fiber.

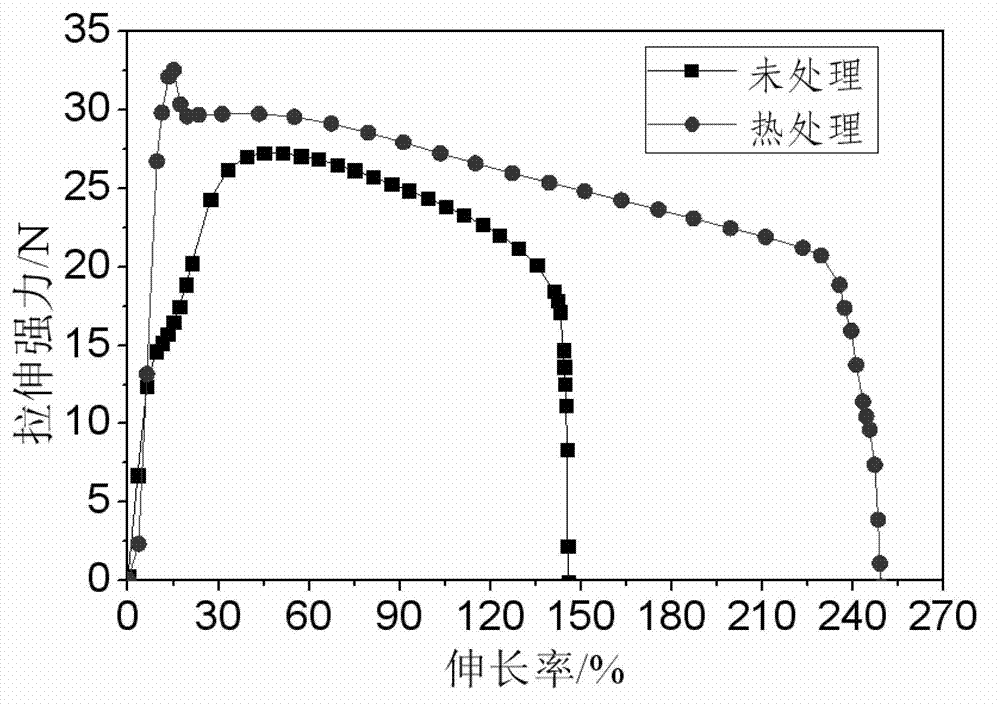

[0064] The primary PTFE hollow fiber was heat-treated at 300°C for 120 minutes; six samples of PTFE hollow fiber 1#, 2#, 3#, 4#, 5# and 6# after heat treatment were stretched to cause holes and sintered to form PTFE hollow fibers. Fi...

Embodiment 2

[0091] 1000g of PTFE dispersion resin is mixed with 200g of auxiliary oil, and the mixture is made into nascent PTFE hollow fiber according to the method in Example 1, with an outer diameter of 5mm and a wall thickness of 1.2mm.

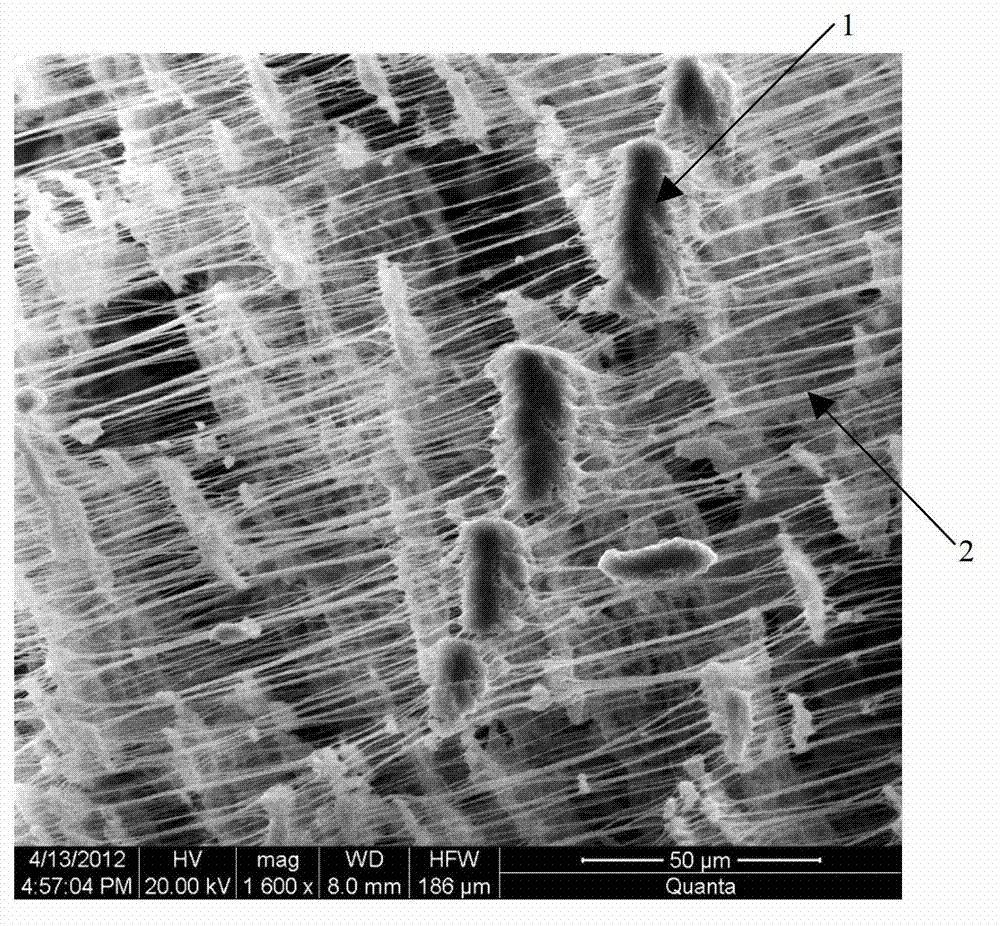

[0092] The primary PTFE hollow fiber is heat-treated at 350°C for 1min; the heat-treated PTFE hollow fiber is stretched 3 times in the axial direction at 200°C, and the stretching rate is 3000mm / min; under tension, the obtained stretched fiber is sintered at 340°C furnace, setting for 2min, and the sample was cooled naturally to obtain a PTFE hollow fiber membrane. Microporous structure on the inner surface of PTFE hollow fiber membrane see Figure 7c , is a sponge-like microporous structure. The outer diameter of the membrane is 4.5mm, the wall thickness is 1.0mm, the average pore diameter is 0.9μm, the porosity is 62%, and the tensile strength at break is 45MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com