Method for preparing superhydrophobic surface through one-step electro-deposition way

A super-hydrophobic surface, electrodeposition technology, applied in the direction of electrolytic inorganic material coating, etc., to achieve the effects of environmental friendliness, good acid-base stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

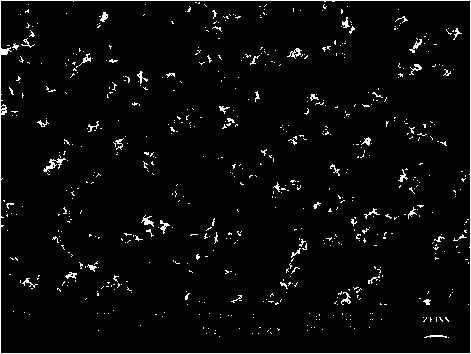

Image

Examples

preparation example Construction

[0012] The steps of the preparation method of the superhydrophobic surface are as follows:

[0013] 1) Add 0.1~5mL long-chain alkyl siloxane dropwise to 50~95mL ethanol or methanol, adjust the pH to 2.0~6.0 with hydrochloric acid, slowly add 50~5mL sodium nitrate or nitric acid with a concentration of 0.2mol / L under stirring Potassium, stirred and hydrolyzed for 1~72h to obtain sedimentation solution;

[0014] 2) Place the conductor substrate to be deposited in the deposition solution as the cathode, and use graphite or platinum sheet as the auxiliary electrode, at 0.1~10.0mA / cm 2 Electrodeposit for 1 to 30 minutes at a current density, take out the substrate and dry the residual solution on the surface with gas to obtain a superhydrophobic surface covered with a nanoporous functionalized silicon dioxide film.

[0015] The conductor matrix to be deposited is gold, silver, platinum, carbon steel, galvanized steel, aluminum, zinc, copper, magnesium, tin and alloys thereof, cond...

Embodiment 1

[0021] Add 0.1 mL of dodecyltrimethoxysilane dropwise to 50 mL of ethanol, adjust the pH to 2.0 with hydrochloric acid, slowly add 50 mL of 0.2 mol / L potassium nitrate, and hydrolyze for 1 hour at room temperature to obtain a deposition solution. The degreased stainless steel is placed in the deposition solution as the cathode, and the platinum sheet is used as the auxiliary electrode, at 10.0mA / cm 2 Electrodepositing under current for 1 min yielded a superhydrophobic nanoporous functionalized silicon dioxide film with a surface water contact angle of 152.6°.

Embodiment 2

[0023] Add 5 mL of dodecyltrimethoxysilane dropwise to 95 mL of methanol, adjust the pH to 6.0 with hydrochloric acid, slowly add 5 mL of 0.2 mol / L potassium nitrate, and hydrolyze at room temperature for 72 hours to obtain a deposition solution. The degreased stainless steel was placed in the deposition solution as the cathode, and the platinum sheet was used as the auxiliary electrode, at 0.1mA / cm 2 Electrodepositing under current for 30 minutes obtained a superhydrophobic nanoporous functionalized silicon dioxide film, and the surface water contact angle was 155.4°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com