Method for preparing hyriopsis cumingii meat enzymolysis protein solution

A technology for enzymatically hydrolyzing proteins and triangular clam, applied in fermentation and other directions, can solve the problems of not considering the effective enzyme activity of alkaline protease, low yield, and low peptide yield, so as to achieve rich content of effective oligopeptides, which is beneficial to The effect of promotion and application and wide range of product uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

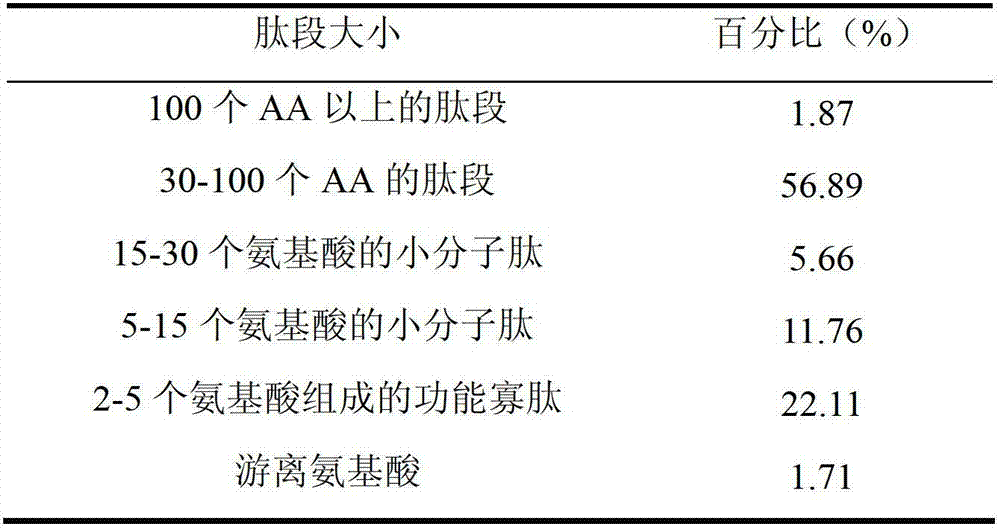

Examples

Embodiment 1

[0026] (1) Preparation of Hyriopsis mussel homogenate

[0027] Rinse the fresh Hyriopsis mussel meat with clean water, initially chop it, put it into a high-speed tissue masher, and homogenize it at 3000rpm for 1-3min to prepare a homogenate. It was determined that the moisture content of the Hyriopsis mussel meat homogenate was 86.78%, and the crude protein content was 47.25% (dry basis).

[0028] (2) Enzymatic hydrolysis of Hyriopsis mussel meat

[0029] Add water to 1000 grams of Hyriopsis meat homogenate in a ratio of 1:2.5 (Hyriopsis mussel meat homogenate: water), stir evenly, adjust the pH to 6.6 by adding 0.1 mol / L HCl, and heat up to 43°C. Then add 2.4L of alkaline protease Alcalase (enzyme activity of 110,000 units / g) according to the ratio of 1000U / g (hypotamus mussel meat homogenate). After enzymatic hydrolysis at a constant temperature of 43°C for 5 hours, boil the enzymatic protein solution for 15 minutes. Enzyme inactivation treatment; then wait for the enzymatic pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com