Method for dilution crystallizationelution and crystallization of cytidine 5'-disodium phosphate

A technology of disodium phosphate and dissolving crystallization, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problem of inconvenient storage, transportation and use, poor particle size distribution and crystal habit quality, and amorphous products containing problems such as low water volume, to achieve the effect of good gloss, uniform particle size and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

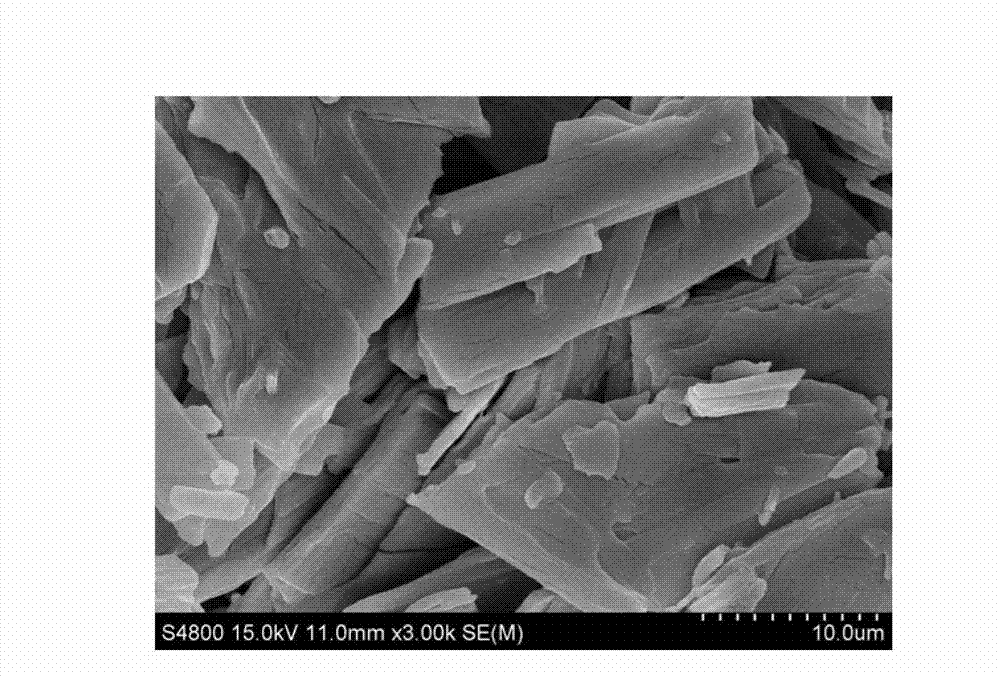

Embodiment 1

[0026] Add 10 L of cytidine 5'-phosphate disodium aqueous solution with a concentration of 10 g / L, pH 7.9, and slowly add 29 L of anti-solvent anhydrous ethanol under the conditions of controlling the water bath at 20 °C and stirring at 150 rpm. After the crystallization was complete, the suspension was filtered with suction, washed with a small amount of ethanol to obtain white crystals, and placed in an oven at 45°C for vacuum drying. The crystallization yield was 95.1%, and the purity was 99.1%.

Embodiment 2

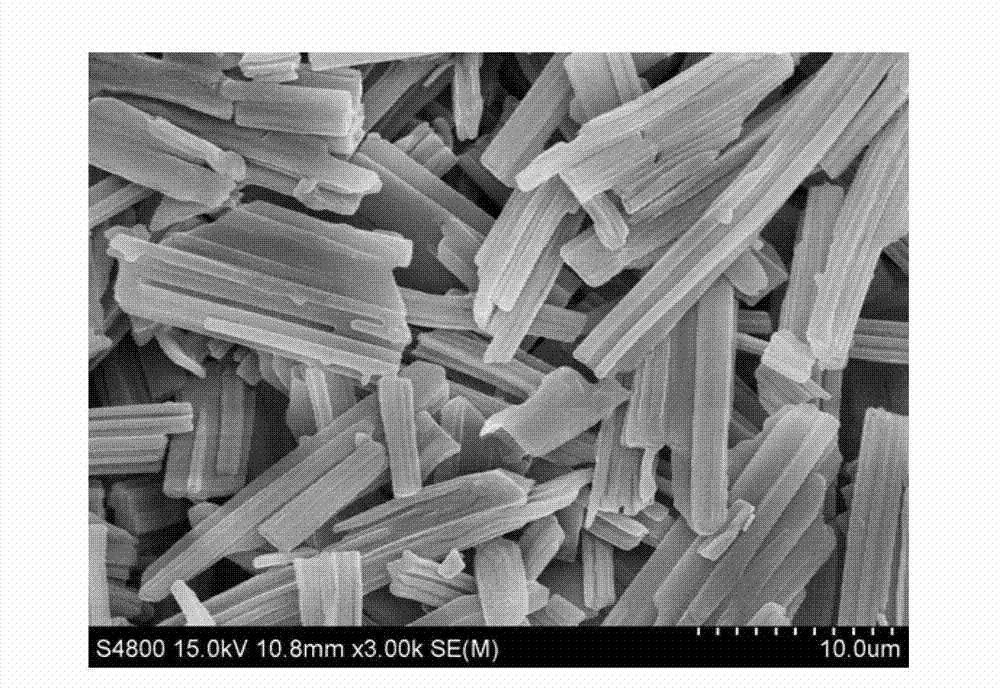

[0028] Add 6 L of cytidine 5'-phosphate disodium aqueous solution with a concentration of 100 g / L, pH 7.0, and slowly add 14 L of anti-solvent methanol under the conditions of controlling the water bath at 10 ° C and a stirring rate of 250 rpm. After the crystallization was complete, the suspension was filtered with suction, washed with a small amount of ethanol to obtain white crystals, and placed in an oven at 45°C for vacuum drying. The crystallization yield was 96.2%, and the purity was 99.3%.

Embodiment 3

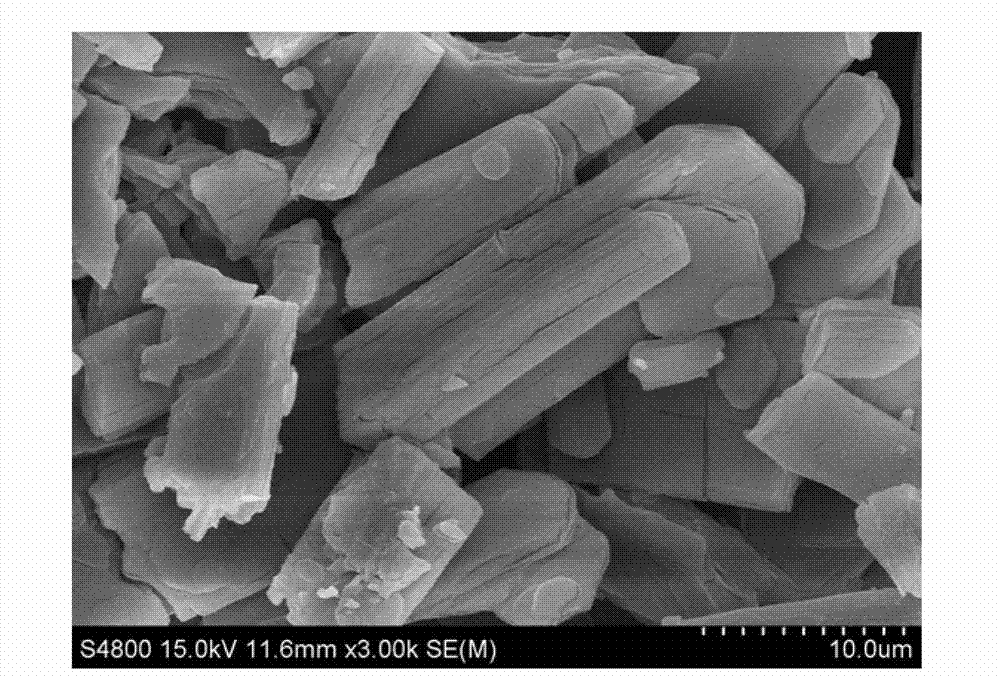

[0030] Add 2L of 180g / L cytidine 5'-disodium phosphate aqueous solution, pH 8.0, in a water bath controlled at 30°C and a stirring rate of 200rpm, and slowly add 4.4L of anti-solvent anhydrous ethanol. After the crystallization was complete, the suspension was filtered with suction, washed with a small amount of ethanol to obtain white crystals, and placed in an oven at 45°C for vacuum drying. The crystallization yield was 95.7%, and the purity was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com