Method for preparing metal surface super-hydrophobicity aluminum coating

A metal surface, super-hydrophobic technology, applied in metal material coating process, special surface, device for coating liquid on the surface, etc., can solve the problems of large surface damage, short preparation process, and the need for a vacuum environment. , to achieve the effect of low equipment cost, good health protection and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

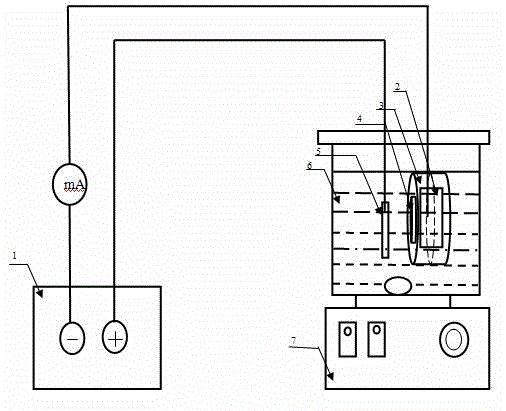

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] In this embodiment, we will specifically describe the operation process of the present invention:

[0027] 1. Preparation of electrolyte: Weigh sulfuric acid and deionized water at a mass ratio of 1:9, slowly add sulfuric acid to deionized water, stir quickly, and prepare dilute sulfuric acid with a mass concentration of 10wt%, and let it stand for use.

[0028] 2. Workpiece pretreatment: Clean the surface of the magnetron sputtered aluminum coating with ethanol, acetone, and deionized water in sequence, take out the sample, and dry it with an electric blower.

[0029] 3. Cathode current treatment: we use such as figure 1 The device shown is for cathodic current treatment on the surface of aluminum coating. The device includes several parts: power supply, sample chamber, sealing sleeve, sealing ring, plate graphite electrode, electrolytic cell and magnetic stirrer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com