Thermomagnetic treatment device and method for magneto-resistive elements of spin valves

A magnetoresistive element and processing device technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as inability to produce, achieve the effects of reducing discreteness, eliminating lattice defects, and improving stability and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

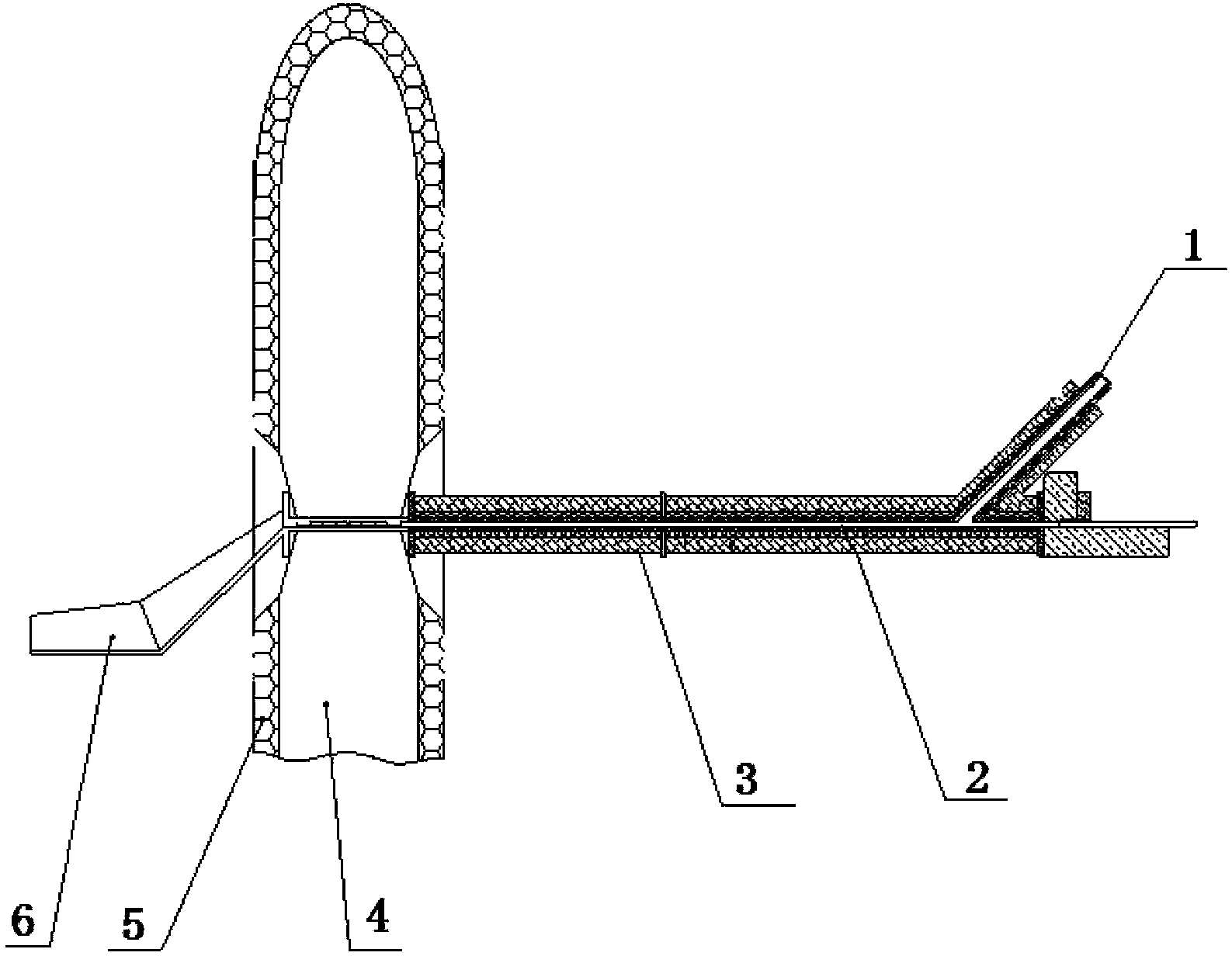

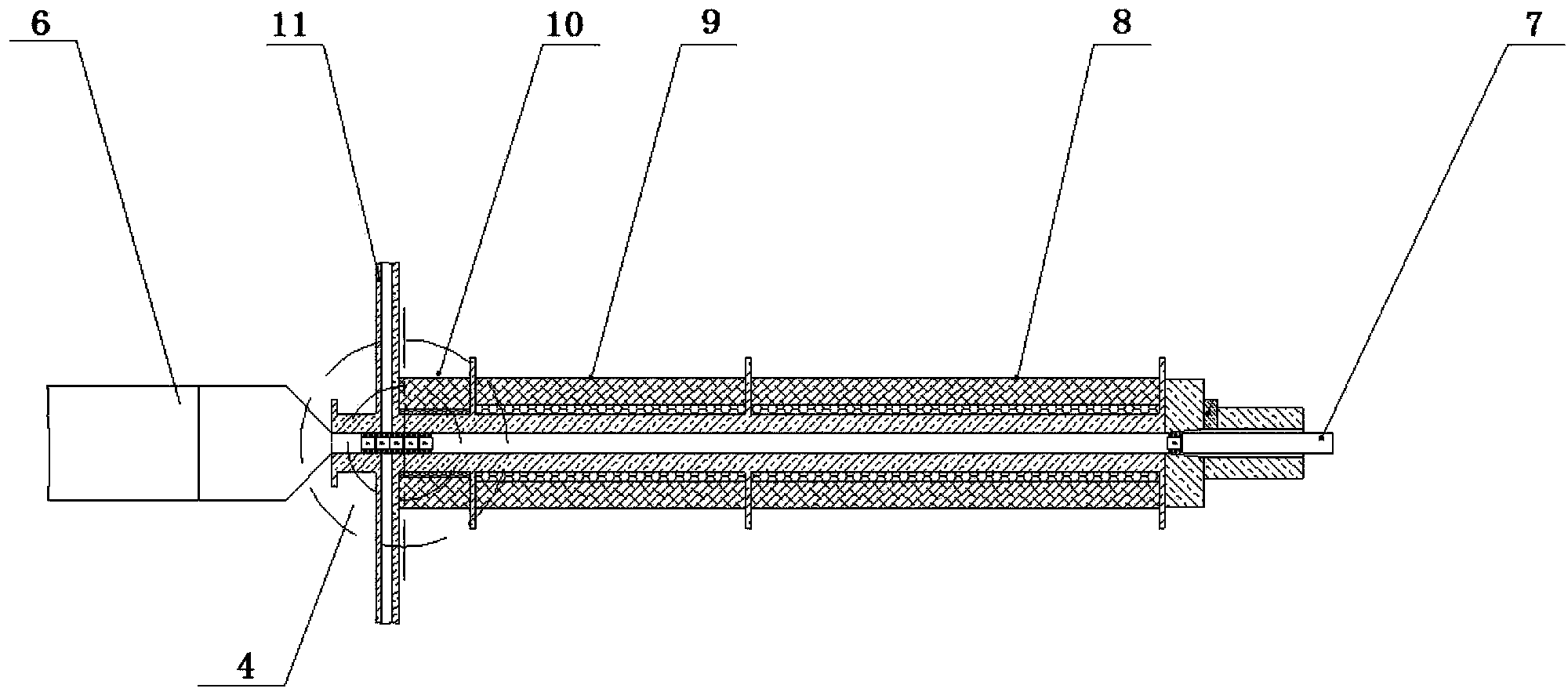

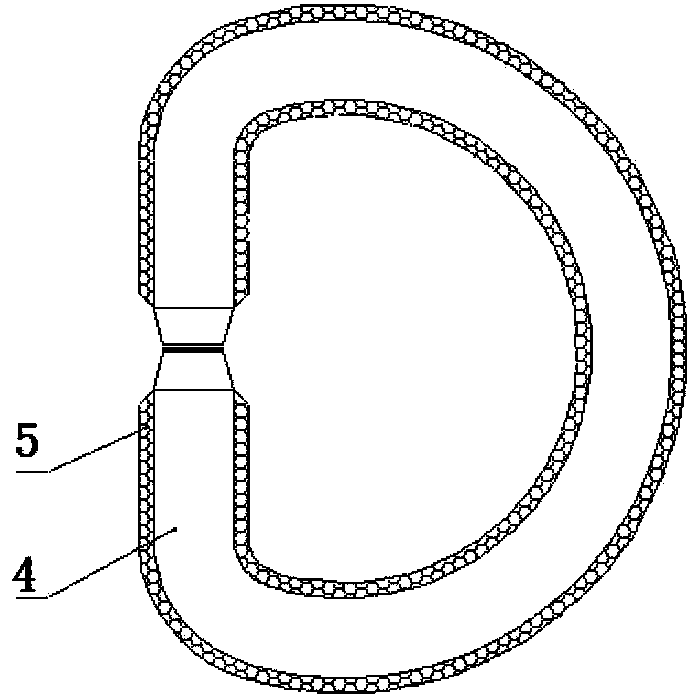

[0034] Such as figure 1 A thermomagnetic treatment device for a spin valve magnetoresistive element is shown, the device includes a guide 2, a heater 3, a "D" shaped soft magnet 4, a ring magnetic field coil 5 and a collector 6;

[0035] The guide 2 is a tubular structure, and a guide groove 13 for the spin valve magneto-resistive element 12 to pass through is opened in the middle of the guide 2 along the axial direction. The two ends of the guide groove 13 are respectively an inlet end and an outlet end. The guide slot 13 can be selected with different cross-sectional dimensions, so as to be suitable for the passage of the components 12 packaged in SOP8, STO-23, and TO-94 respectively; Into the push rod mechanism 7 in the guide vane groove 13; in front of the push rod mechanism 7, the position above the guide vane groove 13 is provided with a preheating zone air inlet 1; on the vertical direction of the guide vane groove 13 outlet end, two The cooling air inlet 11, the air i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com