Zinc oxide-carbonate co-doped cerium barium zirconate proton conductor material and preparation method thereof

A technology of barium cerium zirconate and proton conductor, which is applied in the field of solid oxide fuel cells, can solve the problems of difficult production and application, difficulty in compatibility with high proton conductance and high stability, and reduced material density, and achieve broad market application prospects, The effect of good chemical stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to BaCe 0.4 Zr 0.4 Y 0.2 o 2.9 The stoichiometric ratio, take 1 mole of BaCO 3 , 0.4 mol CeO 2 , 0.4 mol ZrO 2 , 0.1 mole Y 2 o 3 , using absolute ethanol as the medium for ball milling for 8 hours, drying, grinding, sieving, and calcining at 1320°C for 10 hours to obtain cerium barium zirconate matrix powder doped with 10% yttrium oxide by mole. Then add 0.06 mole of ZnO and 0.02 mole of K to 1 mole of matrix powder 2 CO 3 , ball milling and mixing for 6 hours, after drying, grinding and sieving, put the mixed powder into a mold for dry pressing at a pressure of 50MPa, and then undergo isostatic pressing at 200MPa; the green body is sintered in air at 1350°C by buried firing , the heating rate was 5°C / min, and the temperature was kept for 5 hours, and then naturally cooled to room temperature to prepare BaCe 0.4 Zr 0.4 Y 0.2 o 2.9 -ZnO-K 2 CO 3 proton conductor material. Putting this proton conductor material into boiling water at 100°C for 10...

Embodiment 2

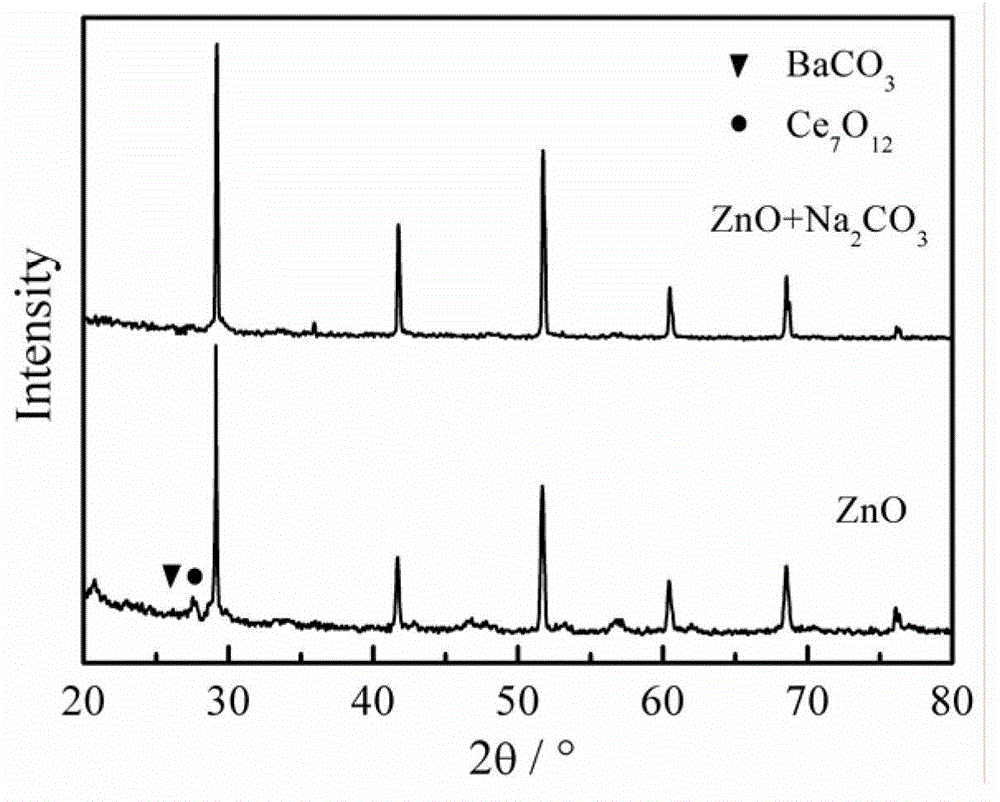

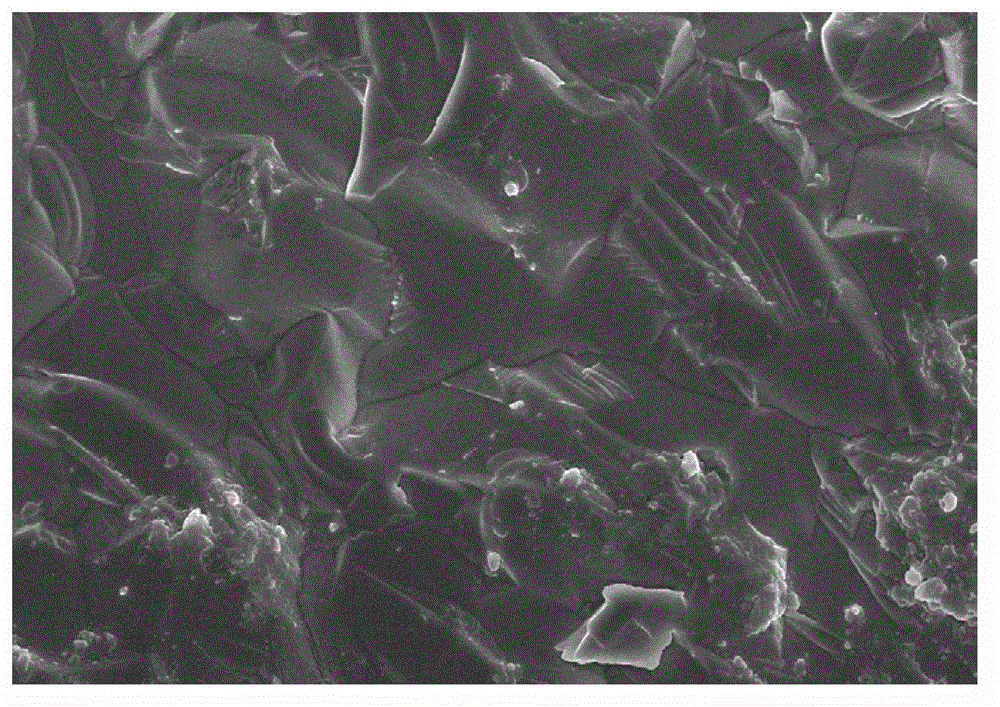

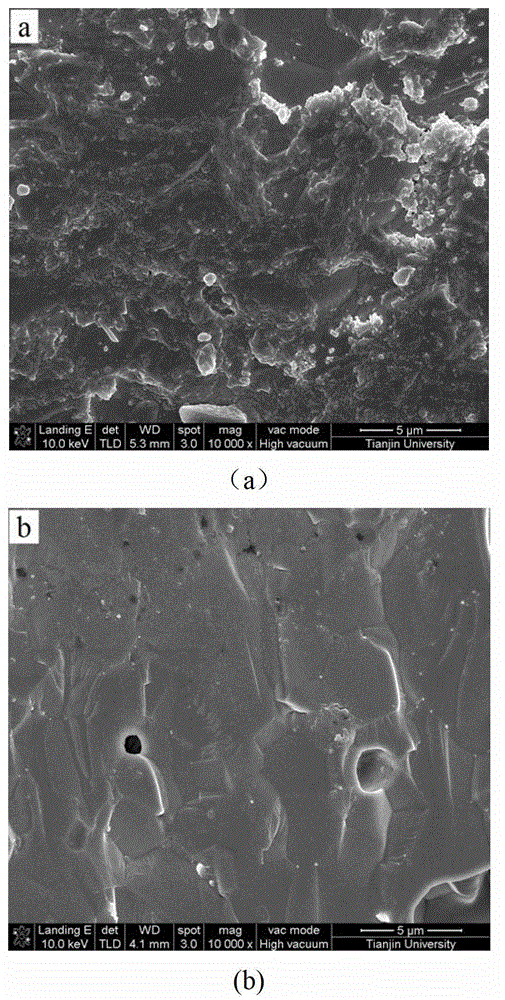

[0027] According to BaCe 0.5 Zr 0.3 Y 0.2 o 2.9 The stoichiometric ratio, weigh 1 mole of BaCO 3 , 0.5 mol CeO 2 , 0.3 mol ZrO 2 , 0.1 mole Y 2 o 3 , using absolute ethanol as the medium for ball milling for 8 hours, then drying, grinding and sieving, and calcining at 1300°C for 10 hours to obtain 10% mole yttrium oxide-doped cerium barium zirconate matrix powder. Then add 0.04 mol of ZnO and 0.005 mol of Na to 1 mol of matrix powder 2 CO 3 , mixed by ball milling for 6 hours, then dried, ground and sieved, then put the mixed powder into a mold for dry pressing at a pressure of 100MPa, and then undergo isostatic pressing at 200MPa; Sintering, heating rate 2°C / min, heat preservation for 2 hours, and then naturally cooling to room temperature to prepare BaCe 0.5 Zr 0.3 Y 0.2 o 2.9 —ZnO—Na 2 CO 3 proton conductor material. figure 2 It is the SEM photo of the cross-section of the proton conductor material after sintering. The proton conductor material was put int...

Embodiment 3

[0029] According to BaCe 0.6 Zr 0.2 Y 0.2 o 2.9 The stoichiometric ratio, weigh 1 mole of BaCO 3 , 0.6 mol CeO 2 , 0.2 mol ZrO 2 , 0.1 mole Y 2 o 3 , using absolute ethanol as the medium for ball milling for 8 hours, drying, grinding and sieving, and calcining at 1250°C for 15 hours to obtain cerium barium zirconate matrix powder doped with 10% yttrium oxide by mole. Then add 0.01 mole of ZnO and 0.03 mole of Li to 1 mole of matrix powder 2 CO 3 , ball milled and mixed for 5 hours, then dried, ground and sieved, the mixed powder was put into a mold for dry pressing at a pressure of 50MPa, and then subjected to 250MPa isostatic pressing; the green body was sintered in air at 1300°C by buried firing , the heating rate was 1°C / min, the temperature was kept for 6 hours, and then naturally cooled to room temperature to prepare BaCe 0.6 Zr 0.2 Y 0.2 o 2.9 -ZnO-Li 2 CO 3 proton conductor material. The proton conductor material was put into a carbon dioxide atmosphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com