Method for preparing antibacterial polyester by use of plant nano-silver

A nano-silver and polyester technology, applied in physical treatment, textile and papermaking, fiber treatment, etc., can solve the problems of not long-lasting antibacterial effect, poor washing resistance, etc., and achieve excellent and durable antibacterial performance, improved dyeing performance, and easy to achieve effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Disperse 0.1 g of corn starch in 10 ml of deionized water, stir at 80 ° C until gelatinized to obtain a starch solution, add it to 20 ml of silver ammonia solution with a concentration of 1 wt%, and mix evenly to obtain a starch-silver ammonia composite solution. The solution is placed under the condition of -20°C for freezing treatment, and after it freezes, it is subjected to pulverization treatment to obtain about 30 g of ice powder with a particle size of 1-3 mm.

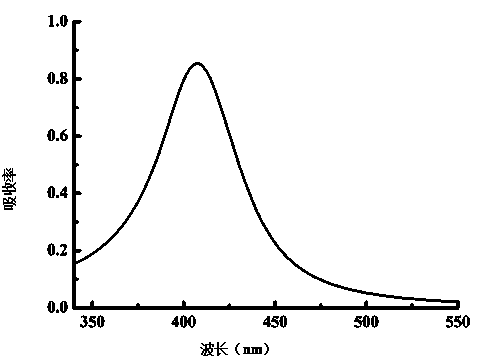

[0034] The aloe vera leaves are washed and peeled with deionized water to obtain aloe vera inner dan, and then cut into pieces, pulverized, filtered, separated and purified to obtain an aloe vera leaf extract, dispersed in deionized water, and prepared 300 ml of aloe vera with a concentration of 10 wt % Aqueous leaf extract solution, NaOH solution adjusts its pH to 11 to obtain alkaline aloe leaf extract; adding the above ice powder to the alkaline aloe leaf extract, stirring at 40°C for 300min, to obtain ...

Embodiment 2

[0038] Disperse 0.05g of tapioca starch in 5ml of deionized water, stir at 90°C until gelatinized to obtain a starch solution, add it to 20ml of silver ammonia solution with a concentration of 0.5wt%, and mix evenly to obtain a starch-silver ammonia composite solution. The composite solution is frozen at -10°C, and crushed after freezing to obtain about 25g of ice powder with a particle size of 1-3mm.

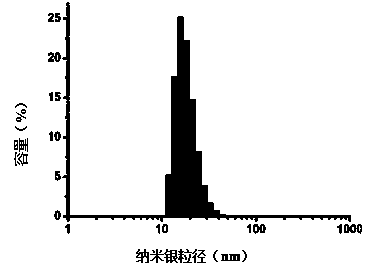

[0039] Wash and peel the cactus with deionized water to obtain inner denim, then cut into pieces, crush, filter, separate, and purify to obtain cactus extract, disperse in deionized water, and prepare 175ml of cactus leaf extract with a concentration of 40 wt%. aqueous solution, and NaOH solution to adjust its pH to 10.7 to obtain an alkaline cactus leaf extract; add the above-mentioned ice powder to the alkaline cactus leaf extract, and stir at 30°C for 300 minutes to obtain a nanosilver hydrosol with a particle size of 8-30nm ;

[0040] Take 4g of polyester fibers and place ...

Embodiment 3

[0047] Take 10g of polyester fabric and place it in 400ml of scouring solution (recipe: 2g of soda ash, 0.4g of detergent, 0.6g of sodium hydrosulfite), and treat it at 100°C for 30 minutes, take it out and wash it until neutral, and dry it at 80-90°C , and then transferred to 200ml of lye (recipe: NaOH 4g, accelerator 0.3g, dispersant 0.5g), treated at 80°C for 30min, taken out, cleaned, and dried to constant weight.

[0048] Get 0.1g of wheat starch and disperse it in 20ml of deionized water, stir at 90°C until gelatinized to obtain a starch solution; prepare an aloe leaf extract and a cactus extract according to the technical scheme of Examples 1 and 2, and prepare aloe with a concentration of 20 wt % Aqueous solution of leaf extract and 30 wt % aqueous solution of cactus leaf extract were mixed according to the volume ratio of 1:1, then starch solution was added to prepare 500ml composite solution, and the pH of the composite solution was adjusted to 10.2 with NaOH solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com