Supercritical CO2 micro-foaming polylactic acid/wood-flour composite material and preparation method thereof

A technology of composite materials and polylactic acid, which is applied in the field of wood-plastic micro-foamed composite materials and their processing and molding, can solve the problems of wood-plastic foamed material wastes not easy to degrade, environmental hazards, etc., and achieve high cell density and less time-consuming , The effect of simple foaming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

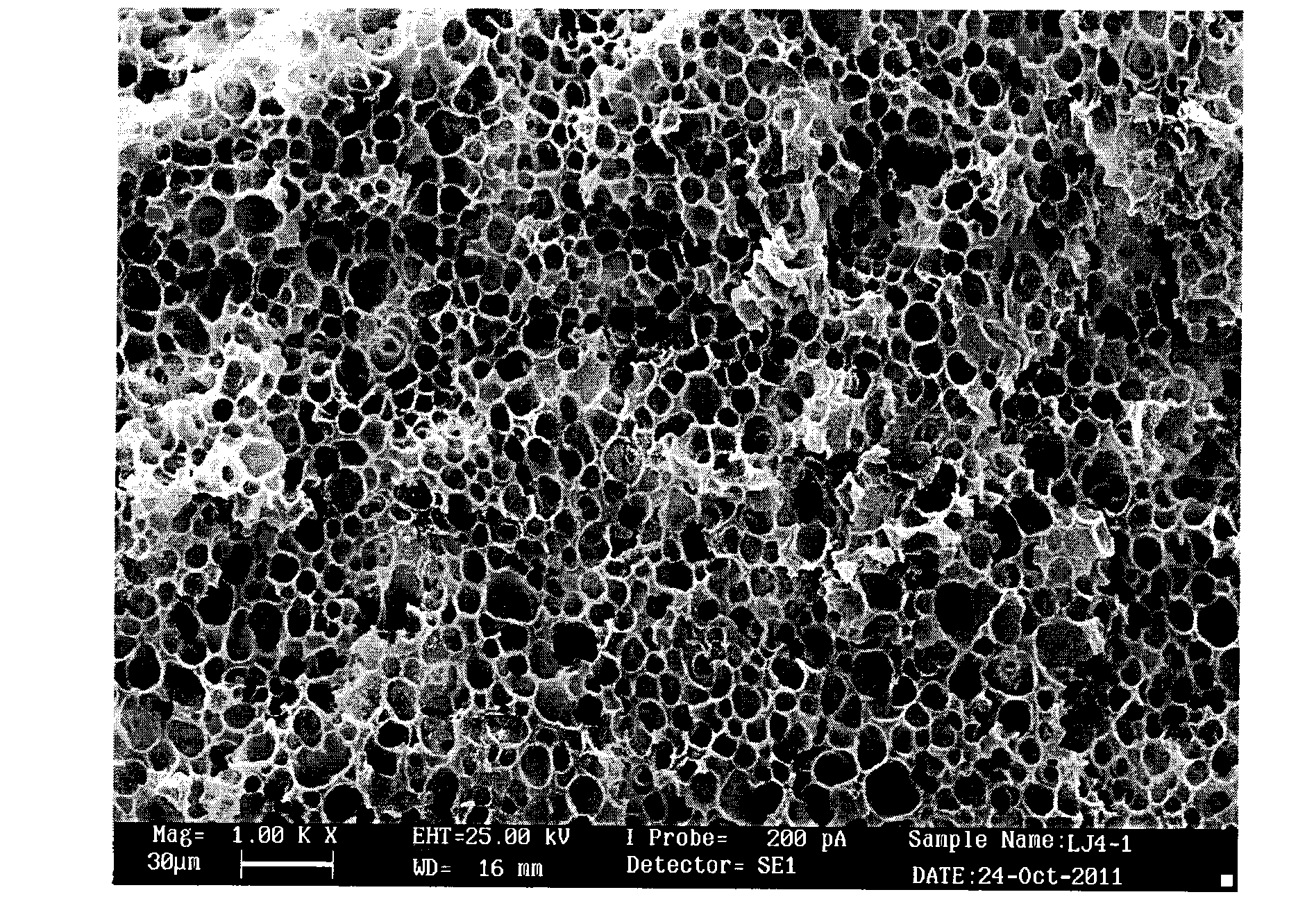

Image

Examples

Embodiment 1

[0017] The raw material components are:

[0018] 41 parts of L-polylactic acid (PLLA, melt index <2g / 10min).

[0019] 16 parts of eucalyptus powder (80 orders).

[0020] 8.2 parts of polyethylene glycol (PEG-400, analytically pure).

[0021] 0.8 parts of coupling agent (γ-methacryloxypropyltrimethoxysilane (KH570, analytically pure)).

[0022] 33 parts of absolute ethanol (analytical pure).

[0023] Glacial acetic acid (analytical pure) ≤ 0.1 parts.

[0024] Simethicone oil (analytical pure) 0.8 parts.

[0025] Add the wood flour and coupling agent solution into a high-speed mixer to mix and modify, the mixing time is 8min; Mixture; the melt blending temperature is 170°C; the kneading time is 20min; the obtained pre-mixture is molded in a flat vulcanizer to obtain a molded sample; the temperature of the molded molding is 170°C; the pressure is 10MPa; the holding time for 8min; the resulting molded sample was placed in supercritical CO 2 Swell in the foaming kettle body,...

Embodiment 2

[0029] The raw material components are:

[0030] 41 parts of L-polylactic acid (PLLA, melt index <2g / 10min).

[0031] 16 parts of eucalyptus powder (80 orders).

[0032] 8.2 parts of polyethylene glycol (PEG-400, analytically pure).

[0033] 0.8 parts of γ-methacryloxypropyltrimethoxysilane (KH570, analytically pure).

[0034] 32.5 parts of absolute ethanol (analytical pure).

[0035] Glacial acetic acid (analytical pure) ≤ 0.1 parts.

[0036] Simethicone oil (analytical pure) 0.8 parts.

[0037] Add the wood flour and coupling agent solution into a high-speed mixer to mix and modify, the mixing time is 8min; Mixture; the melt blending temperature is 170°C; the kneading time is 20min; the obtained pre-mixture is molded in a flat vulcanizer to obtain a molded sample; the temperature of the molded molding is 170°C; the pressure is 10MPa; the holding time for 8min; the resulting molded sample was placed in supercritical CO 2 Swell in the foaming kettle body, control the sw...

Embodiment 3

[0042] The raw material components are:

[0043] 41 parts of L-polylactic acid (PLLA, melt index <2g / 10min).

[0044] 16 parts of eucalyptus powder (80 orders).

[0045] 8.2 parts of polyethylene glycol (PEG-400, analytically pure).

[0046] 0.8 parts of γ-methacryloxypropyltrimethoxysilane (KH570, analytically pure).

[0047] 32.5 parts of absolute ethanol (analytical pure).

[0048] Glacial acetic acid (analytical pure) ≤ 0.1 parts.

[0049] Simethicone oil (analytical pure) 0.8 parts.

[0050] Add the wood flour and coupling agent solution into a high-speed mixer to mix and modify, the mixing time is 8min; Mixture; the melt blending temperature is 170°C; the kneading time is 20min; the obtained pre-mixture is molded in a flat vulcanizer to obtain a molded sample; the temperature of the molded molding is 170°C; the pressure is 10MPa; the holding time for 8min; the resulting molded sample was placed in supercritical CO 2 Swell in the foaming kettle body, control the sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com