Quick-breaking and quick-curing type asphalt emulsifier preparation method

The technology of asphalt emulsifier and solution is applied in the field of preparation of fast-splitting and fast-setting asphalt emulsifier to achieve the effects of good adhesion performance, good storage stability and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

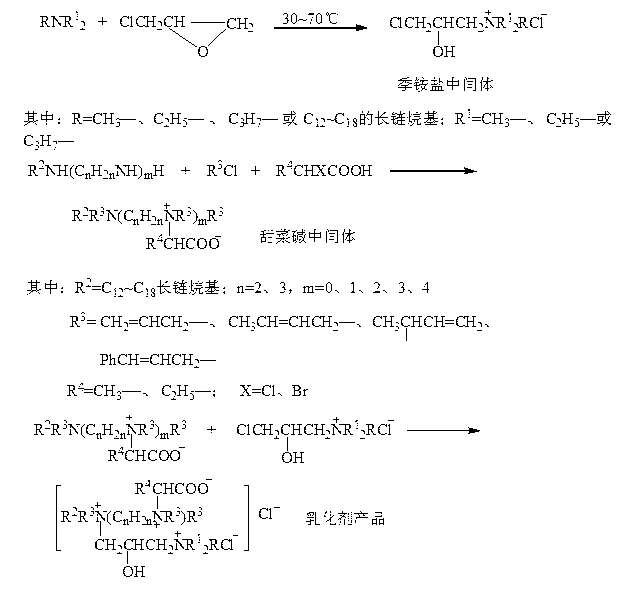

Method used

Image

Examples

Embodiment 1

[0020] Preparation of emulsifier

[0021] Add 16.3g (0.05mol) octadecylpropylenediamine, 7.1g (0.075mol) chloroacetic acid, 5.7g (0.075mol) 3-chloro-1-propene, 10g ethanol and 10g isopropanol to the reaction vessel , stirred and reacted at 70~75°C for 4 hours to obtain a hydrocarbyl-substituted betaine-type intermediate solution;

[0022] Add 13.8g (0.07mol) of 30% trimethylamine aqueous solution and 8.6g (0.085mol) of 36% concentrated hydrochloric acid into the reaction vessel, mix well below 40°C, and then drop 5.6 g (0.06mol) epichlorohydrin, and stirred and reacted at this temperature for 5 hours to obtain a quaternary ammonium salt intermediate solution;

[0023] Add 0.06 mol of the above-prepared quaternary ammonium salt intermediate solution dropwise to 0.05 mol of the hydrocarbyl-substituted betaine-type intermediate solution prepared above at 75~80°C, and stir and react at this temperature for 6 hours to obtain fast-cracking fast Condensed asphalt emulsifier.

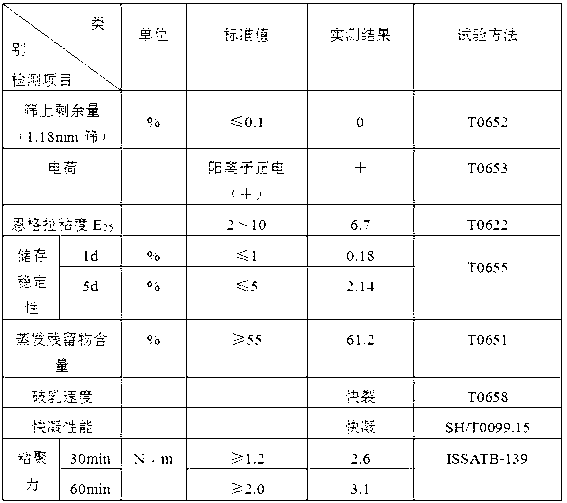

[00...

Embodiment 2

[0029] Emulsifier preparation

[0030] Add 15 g (0.05 mol) of hexadecylpropylenediamine, 8.1 g (0.075 mol) of 2-chloropropionic acid, 6.8 g (0.075 mol) of 1-chloro-2-butene, and 20 g of isopropanol into the reaction vessel , stirred and reacted at 80-85°C for 4 hours to obtain a hydrocarbyl-substituted betaine-type intermediate solution.

[0031] Add 6.1g (0.06mol) of triethylamine, 15g of water and 7.1g (0.07mol) of 36% concentrated hydrochloric acid into the reaction vessel, mix well below 50°C, then drop 5g into it at 40~45°C (0.055mol) epichlorohydrin, stirred and reacted at 50-55° C. for 5 hours to obtain a quaternary ammonium salt intermediate solution.

[0032] Add 0.055 mol of the above-prepared quaternary ammonium salt intermediate solution dropwise to 0.05 mol of the hydrocarbyl-substituted betaine intermediate solution prepared above at 80-85°C, and stir at this temperature for 6 hours to obtain a fast-cracking and fast-setting type Asphalt emulsifier.

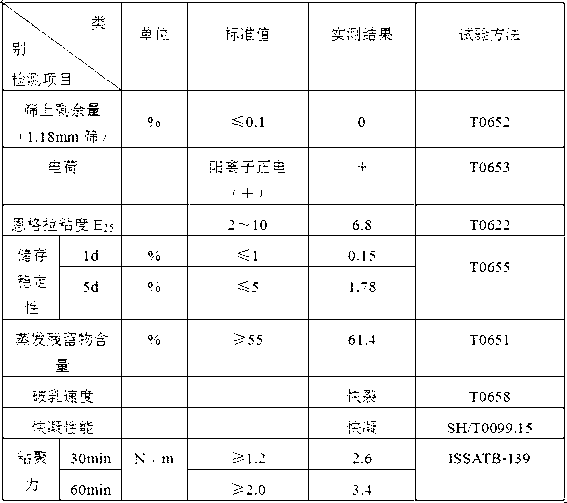

[0033] P...

Embodiment 3

[0038] Preparation of emulsifier

[0039] 20g (0.05mol) N-octadecyltriethylenetetramine, 3.8g (0.05mol) 3-chloro-1-propene, 3.8g (0.025mol) 1-phenyl-3-chloro-1-propene, Add 7.1g (0.075mol) of chloroacetic acid and 20g of ethanol into the reaction vessel, and stir and react at 70~75°C for 5 hours to obtain a solution of a hydrocarbon-substituted betaine-type intermediate.

[0040] Add 13.8g (0.07mol) 30% trimethylamine aqueous solution and 8.6g (0.085mol) 36% concentrated hydrochloric acid into the reaction vessel, mix well below 40°C, then drop 5.6g ( 0.06mol) epichlorohydrin, and stirred at this temperature for 5 hours to obtain a quaternary ammonium salt intermediate solution.

[0041] Add 0.06 mol of the quaternary ammonium salt intermediate solution obtained above dropwise to 0.05 mol of the hydrocarbyl-substituted betaine intermediate solution prepared above at 75~80°C, and stir and react at this temperature for 6 hours to obtain fast cracking and fast setting type asph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com