Device and method for grading lignite by granularity and drying lignite

A technology of particle size classification and drying method, applied in drying gas arrangement, drying, dryer and other directions, can solve the problems of high investment cost, high requirements for manufacturing process and operation control, achieve low equipment cost, easy to optimize configuration, The effect of high energy efficiency of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

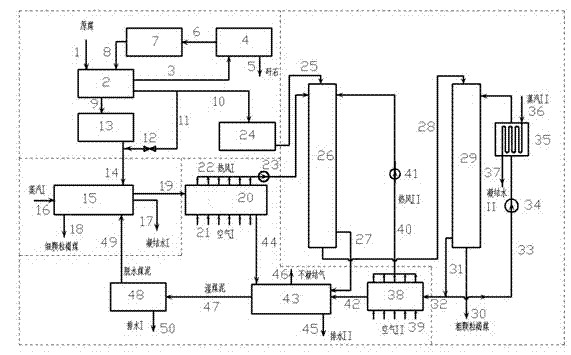

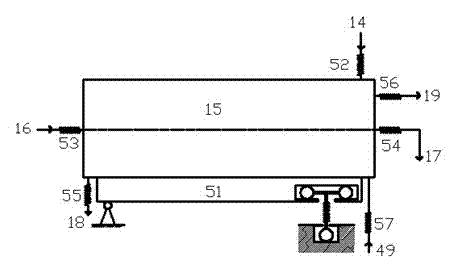

[0033]The raw coal inlet 1 of this device is connected with the vibrating screen machine 2, and the vibrating screen machine 2 is connected with the super large particle conveying pipe 3, the gangue separator 4, the gangue particle removing pipe 6, the crusher 7 and the crushed coal conveying pipe 8, and the gangue outlet is 5 is connected with the gangue sorting machine 4; the two ends of the fine particle pipe 9 are respectively connected with the vibrating screen machine 2 and the fine particle bin 13, and the coarse particle branch pipe 11 is led out from the coarse particle pipe 10, and the fine particle feed pipe 14 is merged with the regulating valve 12 Insert the paddle drier 15, the coarse particle pipe 10 is connected to the coarse particle bin 24; the two ends of the fine particle feed pipe 14 are respectively connected with the fine particle bin 13 and the paddle drier 15, the paddle drier steam pipe 16, the paddle drier The condensate pipe 17 of the leaf dryer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com