Oil absorption material containing silicon polymer and preparation methods thereof

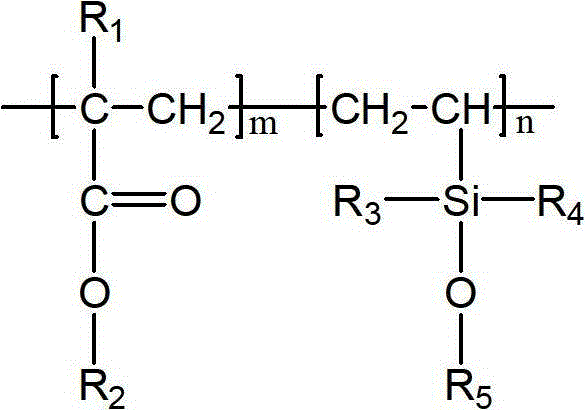

A technology of oil-absorbing materials and silicon polymers, applied in chemical instruments and methods, and other chemical processes, can solve problems such as endangering aquatic organisms, endangering human health, and polluting the water environment, achieving good oil retention performance, improving hydrophobic performance, Strong oil-water selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Methyl methacrylate 1.000g, vinylmethyldimethoxysilane 10.000g, divinylbenzene 0.055g, benzoyl peroxide 0.055g, toluene 0.550g, polyvinyl alcohol 0.055g, clean water 11.660g Add it into the reactor, and stir at room temperature for more than 30 minutes under the protection of nitrogen; then raise the temperature of the reactor to 60°C, and terminate the reaction after 9 hours. The product is washed with deionized water after ethanol precipitation, placed in a vacuum drying oven, and dried at 60°C to obtain the silicon-containing polymer oil-absorbing material.

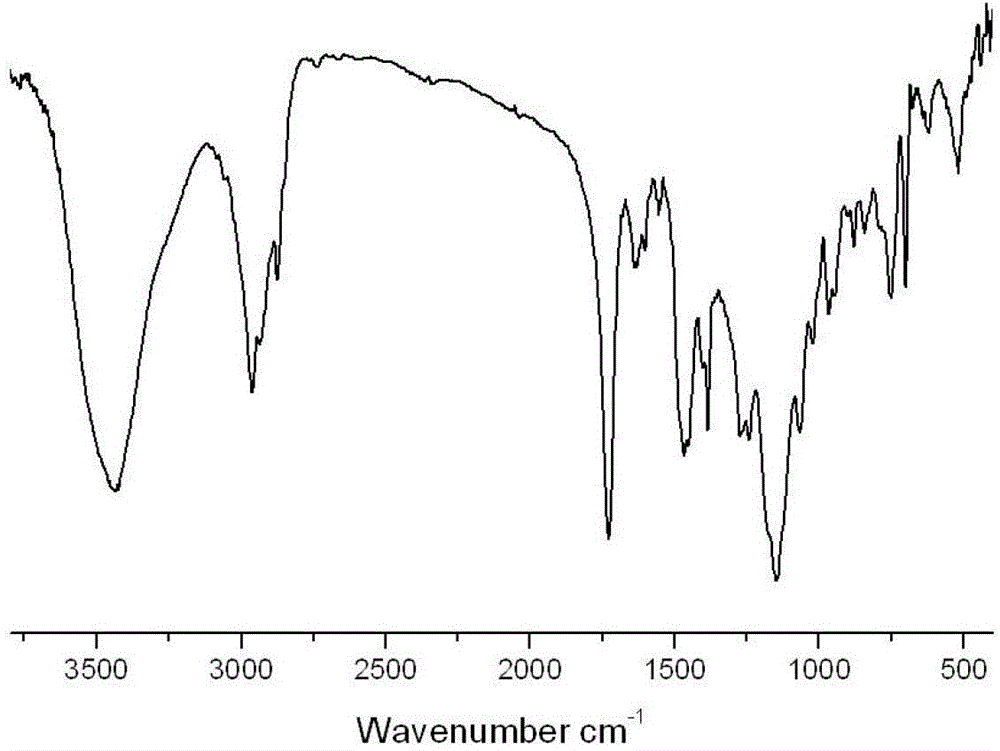

[0046] The infrared analysis spectrum of the prepared silicon-containing polymer oil-absorbing material is as follows figure 1 As shown, 2961cm -1 The asymmetric vibration of the aliphatic C-H bond appears at the position, and it can be judged that the product has CH 3 group; another 2875cm -1 is the symmetrical vibration of CH2. 1728cm -1 The characteristic absorption peak of ester group C=O bond appeared. ...

Embodiment 2

[0050] Lauryl methacrylate 10.000g, vinyl ethyl dimethoxysilane 2.000g, diallyl phthalate 0.120g, azobisisobutyronitrile 0.120g, toluene 1.200g, polyvinyl alcohol 0.180g g. Add 40.320 g of clean water into the reactor, and stir at room temperature for more than 30 minutes under the protection of nitrogen; then raise the temperature of the reactor to 70° C., and stop the reaction after 7 hours. The product is washed with deionized water after ethanol precipitation, placed in a vacuum drying oven, and dried at 80°C to obtain the silicon-containing polymer oil-absorbing material. The oil absorption ratios of the obtained silicon-containing polymer oil-absorbing materials to various oils are shown in Table 1.

Embodiment 3

[0052] 10.000g of octadecyl methacrylate, 0.500g of vinyl dimethyl methoxysilane, 0.210g of polyethylene glycol dimethacrylate, 0.315g of cerium ammonium nitrate, 2.100g of acetone, 0.315g of polyvinyl alcohol, Add 105.000g of clean water into the reactor, and stir at room temperature for more than 30min under the protection of nitrogen; then raise the temperature of the reactor to 90°C, and stop the reaction after 5h. The product is washed with deionized water after ethanol precipitation, placed in a vacuum drying oven, and dried at 100°C to obtain the silicon-containing polymer oil-absorbing material. The oil absorption ratios of the obtained silicon-containing polymer oil-absorbing materials to various oils are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com