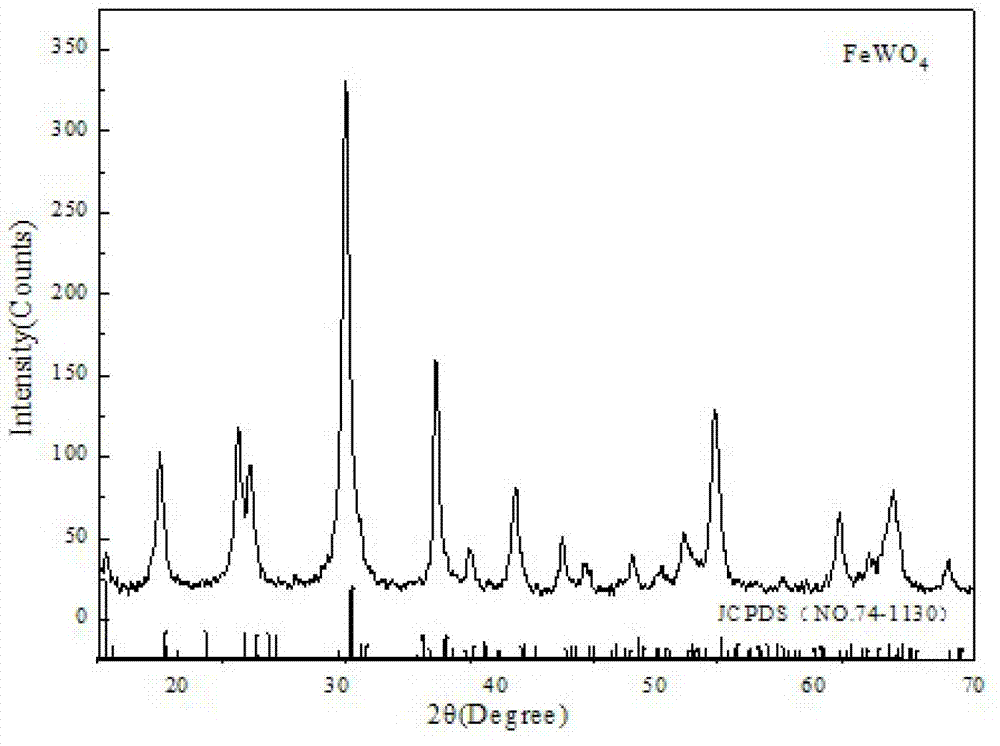

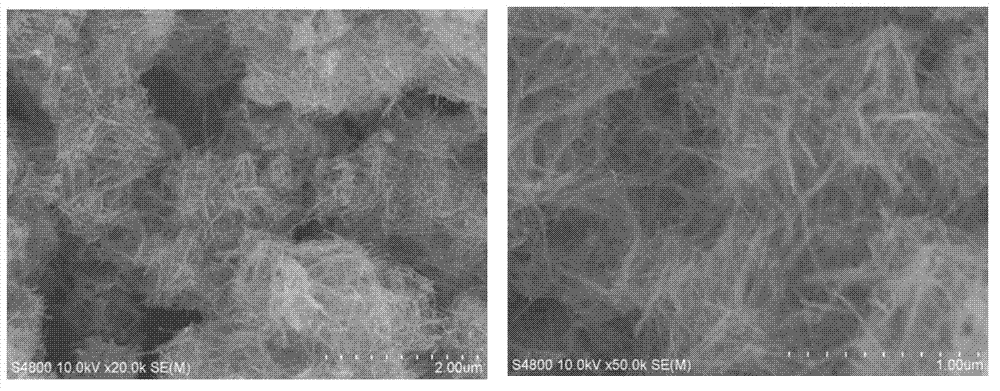

Preparation method of FeWO4 nanowire

A nanowire and SO4 technology, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of expensive equipment and instruments, low utilization rate of raw materials, long preparation cycle, etc., and achieves convenient operation, good crystallization, and reduced preparation time. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Analytical pure ammonium ferrous sulfate [(NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O] add in distilled water, and constantly stir, be mixed with the ferrous sulfate ammonia solution that concentration is 0.1mol / L, add chemically pure PVPK30 in the ferrous sulfate ammonia solution, make [Fe 2+ ]: PVPK30=1:0.9 molar ratio to obtain solution A;

[0016] 2) The analytically pure sodium tungstate [Na 2 WO 4 2H 2 O] Add in distilled water, and keep stirring to prepare a sodium tungstate solution with a concentration of 0.1mol / L, and add analytically pure dimethylformamide at the same time, so that the concentration of dimethylformamide is 5mmol / L to obtain a mixed solution B;

[0017] 3) Take solution A and solution B according to the volume ratio of 1:1, add solution B to solution A drop by drop, magnetically stir evenly, pour it into the hydrothermal reaction kettle, and control the filling degree at 60%; then seal the hydrothermal reaction kettle , control the hydrothermal ...

Embodiment 2

[0022] 1) Analytical pure ammonium ferrous sulfate [(NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O] add in distilled water, and constantly stir, be mixed with the ferrous sulfate ammonia solution that concentration is 0.2mol / L, add chemically pure PVPK30 in the ferrous sulfate ammonia solution, make [Fe 2+ ]: PVPK30=1:1 molar ratio to get solution A;

[0023] 2) The analytically pure sodium tungstate [Na 2 WO 4 2H 2 O] Add in distilled water, and keep stirring to prepare a sodium tungstate solution with a concentration of 0.2mol / L, and add analytically pure dimethylformamide at the same time, so that the concentration of dimethylformamide is 6mmol / L to obtain a mixed solution B;

[0024] 3) Take solution A and solution B according to the volume ratio of 1:1, add solution B to solution A drop by drop, magnetically stir evenly, pour it into the hydrothermal reaction kettle, and control the filling degree at 70%; then seal the hydrothermal reaction kettle , control the hydrothermal tempe...

Embodiment 3

[0027] 1) Analytical pure ammonium ferrous sulfate [(NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O] add in distilled water, and constantly stir, be mixed with the ferrous sulfate ammonia solution that concentration is 0.3mol / L, add chemically pure PVPK30 in the ferrous sulfate ammonia solution, make [Fe 2+ ]: PVPK30=1:1.2 molar ratio to obtain solution A;

[0028] 2) The analytically pure sodium tungstate [Na 2 WO 4 2H 2 O] Add in distilled water, and keep stirring to prepare a sodium tungstate solution with a concentration of 0.3mol / L, and add analytically pure dimethylformamide at the same time, so that the concentration of dimethylformamide is 7mmol / L to obtain a mixed solution B;

[0029] 3) Take solution A and solution B according to the volume ratio of 1:1, add solution B to solution A drop by drop, magnetically stir evenly, pour it into the hydrothermal reaction kettle, and control the filling degree at 65%; then seal the hydrothermal reaction kettle , control the hydrothermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com