Efficient extraction system and extraction method of grape seed extract

An extraction method and technology of an extraction system, which are applied to an efficient extraction system and extraction field of grape seed extract, can solve the problems of lack of extraction equipment, high solvent consumption, energy waste, etc., so as to reduce the difficulty of solvent recovery, ensure the extraction yield, Equipment matching reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: The high-efficiency extraction system and extraction method of the grape seed extract are as follows.

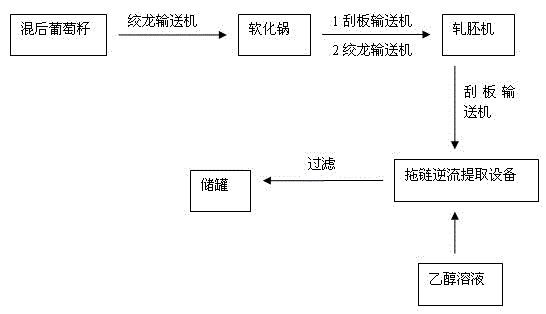

[0031] figure 1 As shown, the high-efficiency extraction system of the grape seed extract is composed of a conveying device, a softening pot, a flaking machine, a continuous countercurrent extraction equipment, a liquid injection pump and a storage tank; the entrance of the softening pot passes through the auger conveyor Realize the input of materials; the outlet of the softening pot conveys the materials to the inlet of the flaking machine through the scraper conveyor and the auger conveyor; the outlet of the flaking machine conveys the materials to the inlet of the drag chain countercurrent extraction equipment through the scraper conveyor ; The material discharged from the outlet of drag chain countercurrent extraction equipment is collected in the storage tank after being filtered.

[0032] The efficient extraction method of the grape seed extract is: ...

Embodiment 2

[0037] Embodiment 2: The efficient extraction method of this grape seed extract is as follows;

[0038] (1) Put the grape seed and safflower seed meal into the softening pot through the auger conveyor, the mass of the safflower seed meal is 12% of the grape seed mass, the feeding speed is 600kg / h, and 5% of the feeding mass is added Water is used for softening. After softening, the water content of the material is 14%, the outlet temperature is 65°C, and the softening time is 30 minutes;

[0039] (2) After softening, the material is transported to the flaking machine through the scraper conveyor and the auger conveyor for flaking treatment. The pressure of the hydraulic station of the flaking machine is 0.48MPa, and the thickness of the embryo cake is 0.43mm;

[0040] (3) After flaking, the material is transported to the towline countercurrent extraction equipment through the scraper conveyor, and 60% (V / V) ethanol aqueous solution is put into the solvent feeding port for leac...

Embodiment 3

[0043] Embodiment 3: The efficient extraction method of this grape seed extract is as follows;

[0044] (1) Mix the grape seeds and cottonseed meal and put them into the softening pot through the auger conveyor. The quality of the cottonseed meal is 30% of the mass of the grape seeds. The feeding speed is 550kg / h. After softening, the moisture content of the material is 15%, the outlet temperature is 80°C, and the softening time is 30 minutes;

[0045] (2) After softening, the material is transported to the flaking machine through the scraper conveyor and the auger conveyor for flaking treatment. The pressure of the hydraulic station of the flaking machine is 0.55MPa, and the thickness of the embryo cake is 0.40mm;

[0046] (3) After flaking, the material is transported to the drag chain countercurrent extraction equipment through the scraper conveyor, and 65% (V / V) ethanol aqueous solution is put into the solvent feeding port for leaching, and the feeding speed is 2.5m3 / h. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com