Nano-hydroxyapatite/chitosan/chondroitin sulfuric acid composite stent

A technology of nano-hydroxyapatite and chondroitin sulfate, which is applied in the fields of medical science and prostheses, can solve problems such as uneven dispersion of hydroxyapatite, decline in mechanical properties of materials, and weak interface binding force, so as to promote adhesion and growth, improved mechanical properties, and controllable crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

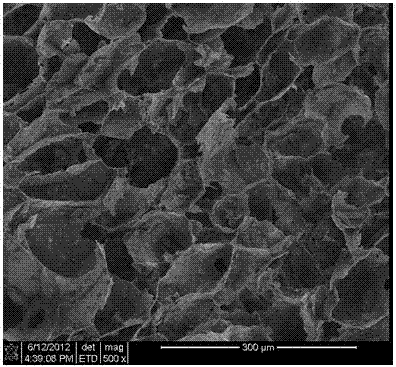

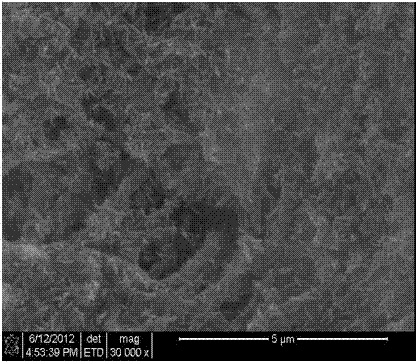

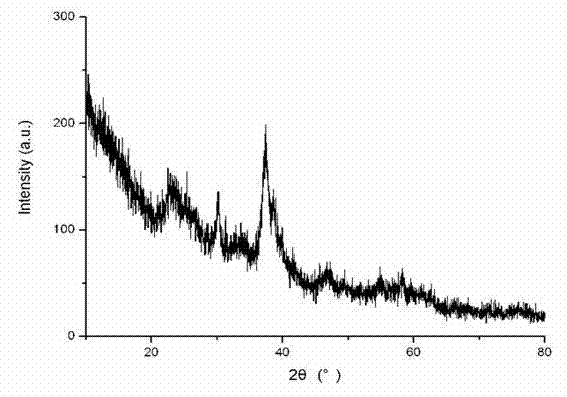

Image

Examples

Embodiment 1

[0027] 1) Prepare 2mol / L calcium nitrate salt solution and 1.2mol / L potassium dihydrogen phosphate solution; the mass ratio of chitosan and chondroitin sulfate is 10:1;

[0028] 2) Dissolve the chitosan / chondroitin sulfate in the mass ratio in 1% acetic acid solution, and stir evenly;

[0029] 3) Slowly add a certain amount of calcium nitrate salt solution and potassium dihydrogen phosphate solution to the above chitosan / chondroitin sulfate mixture, and stir for 1 hour; where n(Ca 2+ ):n(PO 4 3- )=1.67:1, the mass ratio of organic components to theoretically formed HAP is 1:0.4;

[0030] 4) Add the cross-linking agent EDC / NHS, the concentration of EDC is 2 mg / mL, the molar ratio of EDC / NHS is 1.5:1, cross-link at room temperature for 6 hours; the final mixture is poured into the mold, moved to a refrigerator at 4°C for 4 hours, and then Freeze in a -10°C ultra-low temperature refrigerator for at least 12 hours, then transfer to a freeze dryer to freeze dry until completely ...

Embodiment 2

[0034] 1) Prepare 2mol / L calcium nitrate solution and 0.6mol / L potassium dihydrogen phosphate solution; the mass ratio of chitosan and chondroitin sulfate is 5:1;

[0035] 2) Dissolve the chitosan / chondroitin sulfate in the ratio in 1% acetic acid solution, and stir evenly;

[0036] 3) Slowly add a certain amount of calcium nitrate solution and potassium dihydrogen phosphate solution to the uniformly mixed chitosan / chondroitin sulfate mixture, and stir for 1 hour; where n(Ca 2+ ):n(PO4 3- )=1.67:1, the mass ratio of organic components to theoretically formed HAP is 1:0.5;

[0037] 4) Add cross-linking agent EDC / NHS, the concentration of EDC is 2.5 mg / mL, the molar ratio of EDC / NHS is 2:1, cross-link at room temperature for 5 hours; the final mixture is poured into the mold, moved to 4 ° C refrigerator for 4 hours, and then Freeze in a -20°C ultra-low temperature refrigerator for at least 12 hours, then transfer to a freeze dryer to freeze dry until completely dehydrated;

...

Embodiment 3

[0041] 1) Prepare 1mol / L calcium nitrate solution and 1.2mol / L disodium hydrogen phosphate solution; the mass ratio of chitosan and chondroitin sulfate is 10:3;

[0042] 2) Dissolve the chitosan / chondroitin sulfate in the ratio in 1% acetic acid solution, and stir evenly;

[0043] 3) Slowly add a certain amount of calcium nitrate solution and disodium hydrogen phosphate solution to the homogeneously mixed chitosan / chondroitin sulfate mixture, and stir for 1 hour; where n(Ca 2+ ):n(PO 4 3- )=1.67:1, the mass ratio of organic components to theoretically formed HAP is 1:0.6;

[0044] 4) Add cross-linking agent EDC / NHS, the concentration of EDC is 3 mg / mL, the molar ratio of EDC / NHS is 2.5:1, cross-link at room temperature for 5 hours; the final mixture is poured into the mold, moved to 4 °C refrigerator for 6 hours, and then put Freeze in a -80°C ultra-low temperature refrigerator for at least 12 hours, and then transfer to a freeze dryer to freeze-dry until completely dehydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com