Method for preparing high-strength and high-conductivity copper-based alloy coating by means of laser-induction hybrid cladding

A technology of copper-based alloy and base alloy, which is applied in the coating process and coating of metal materials, can solve the problems of easy oxidation and other problems, and achieve the effect of compact structure, reduced temperature gradient and low dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

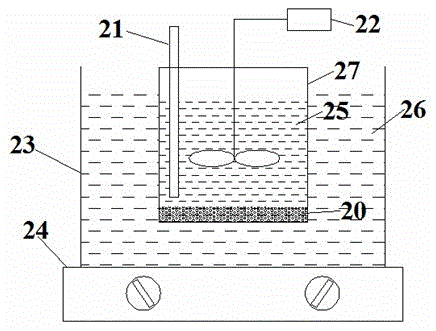

Embodiment 1

[0027] Laser-induction composite cladding was used on the surface of LY12 aluminum alloy (Al-4.4Cu-1.5Mg-0.6Mn) to prepare a high-strength and high-conductivity copper-based alloy coating with a size of 80 mm×50mm×1.2 mm (length×width×height). , The performance tested is: hardness up to 300HBS, tensile strength 820MPa, electrical conductivity 78%IACS, softening temperature 550℃, dilution rate 8.5%, wear resistance can be improved by 2.5 times compared with LY12 aluminum alloy, dense microstructure, no pores It forms a metallurgical bond with the crack and the matrix. The specific implementation process is as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown:

[0028] (1) First, the special copper-based alloy powder 20 is pickled and activated. Among them, the chemical composition of the special copper-based alloy powder 20 is: Al 5.0 wt.%, Cr 0.8 wt.%, Zr 0.05 wt.%, Ni 2 wt.%, Fe 10 wt.%, the balance is Cu, the average grain The diameter is 20 μm; the pick...

Embodiment 2

[0035] The surface of AM60B magnesium alloy (Mg-8.5Al-0.2Mn-0.55Zn-0.1Si-0.03Cu-0.002Ni-0.005Fe) was clad by laser-induction composite cladding, and the preparation size was 60 mm×30 mm×2.0 mm (length× Width × height) high-strength and high-conductivity copper-based alloy coating, the performance of the test is: hardness up to 350HBS, tensile strength 850MPa, electrical conductivity 82% IACS, softening temperature 580 ℃, dilution rate 7.5%, wear resistance compared to AM60B magnesium alloy It can be improved by 4 times, the microstructure is dense, there are no pores and cracks, and it forms a metallurgical bond with the matrix. The specific implementation process is as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown:

[0036] (1) First, the special copper-based alloy powder 20 is pickled and activated. Among them, the chemical composition of the special copper-based alloy powder 20 is: Al 10 wt.%, Cr 0.5 wt.%, Zr 0.08 wt.%, Ni 3.5 wt.%, Fe 15 wt.%, the b...

Embodiment 3

[0043] Laser-induction composite cladding is used on the surface of QA15 copper alloy (Cu-7Al) to prepare a high-strength and high-conductivity copper-based alloy coating with a size of 120 mm × 60 mm × 2.5 mm (length × width × height). The detected properties are: hardness Up to 400HBS, tensile strength 870MPa, electrical conductivity 85%IACS, softening temperature 600°C, dilution rate 7.0%, wear resistance can be increased by 5 times compared with QA15 copper alloy, dense microstructure, no pores and cracks, and metallurgy with the matrix combined. The specific implementation process is as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown:

[0044] (1) First, the special copper-based alloy powder 20 is pickled and activated. Among them, the chemical composition of the special copper-based alloy powder 20 is: Al 15 wt.%, Cr 1.5 wt.%, Zr 1.0 wt.%, Ni 4.5 wt.%, Fe 5 wt.%, the balance is Cu, the average grain The diameter is 45 μm; the pickling and activatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com