Preparation method of bainite-martensite automobile gear nodular cast iron

A technology of martensite and bainite, which is applied in the field of preparation of nodular cast iron for automotive gears, can solve the problems of complex preparation process, fatigue cracks, high cost, etc., and achieve simple preparation process, low preparation cost, good toughness and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

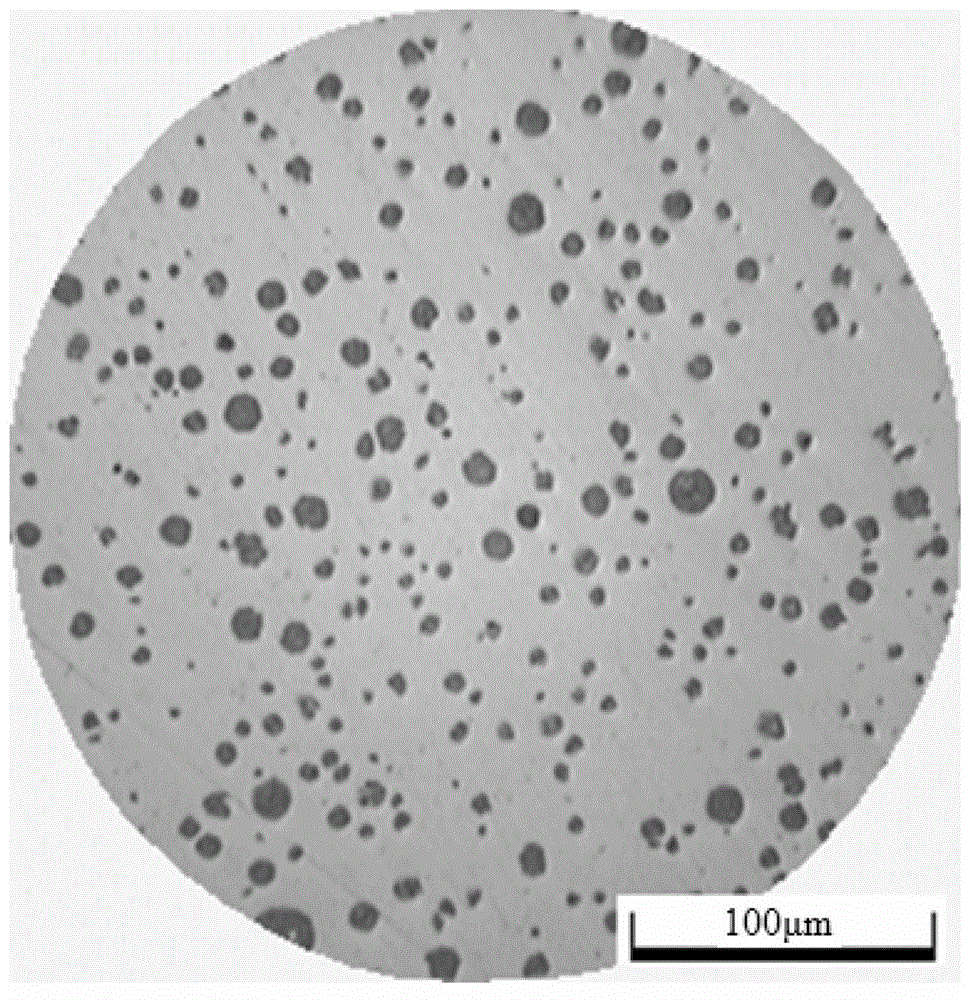

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of the bainite-martensitic automotive gear ductile iron of the present embodiment is carried out according to the following steps:

[0018] 1. Smelting molten iron: First weigh 60~65 parts of Q10 pig iron, 25~30 parts of ductile iron return charge and 10~15 parts of scrap steel according to the mass parts, and then mix Q10 pig iron, ductile iron return charge and The ratio of the total mass of scrap steel is (1.5~2.0): 100, based on the ratio of the mass of electrolytic copper to the total mass of Q10 pig iron, nodular iron and scrap steel (0.6~1.0): 100, based on the mass of ferromolybdenum and Q10 pig iron , The ratio of the total mass of ductile iron return charge to scrap steel is (0.3~0.6): 100. Weigh the nickel plate, electrolytic copper and ferromolybdenum, and then weigh the weighed Q10 pig iron, ductile iron return charge, scrap steel, nickel plate, electrolytic Add copper and ferromolybdenum into the intermediate...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the total mass of impurities in Q10 pig iron in step 1 is ≤0.1%, and the components and the mass fractions of each component in scrap steel are: C: 0.17%~0.21%, S: 0.012%~0.016%, P: 0.020%~0.024%, Mn: 0.26%~0.30%, Si: 0.30%~0.40%, and other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of Ni in the nickel plate in step 1 is 99.9% to 99.99%, and other steps and parameters are the same as Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com