Production method for multi-element alloy steel

A production method and alloy steel technology, applied in metal processing equipment, coating, casting and forming equipment, etc., can solve the problems of metallographic structure, mechanical properties that cannot meet the technical requirements, and product quality that is difficult to pass the acceptance inspection, so as to improve mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The inner tube of the 200-ton electric wheel vehicle is generally made of forgings.

[0024] The invention is produced by centrifugal casting of multi-element alloy steel, and the performance and structure meet the requirements, and the cost is 80% of that produced by the forging process.

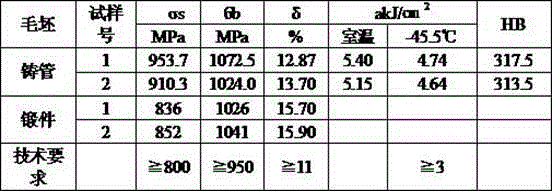

[0025] In the design requirements of multi-element alloy steel (ZG30Ni2Cr1MoV), except for Fe element, other chemical components are as follows:

[0026] C: 0.30~0.33%; Si: 0.20~0.35%; Mn: 0.65~0.80%; P≤0.025%; S≤0.025%; Cr: 0.90~1.05%; Ni: 2.15~2.35%; %; V: 0.10-0.15%.

[0027] The main features of the multi-element alloy steel are high strength and sufficient toughness, many types of alloying elements, and a narrow range of requirements.

[0028] The present invention selects centrifugal casting to produce the inner tube, and requires the following controls from aspects such as smelting, casting and heat treatment processes:

[0029] 1. Smelting:

[0030] 1. Smelting equipment:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com