Method for recycling waste aluminum ring-pull cans in green circular relegation way

An environmentally friendly technology for pop-top cans, which is applied in the field of green recycling and re-use of waste aluminum pop-top cans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

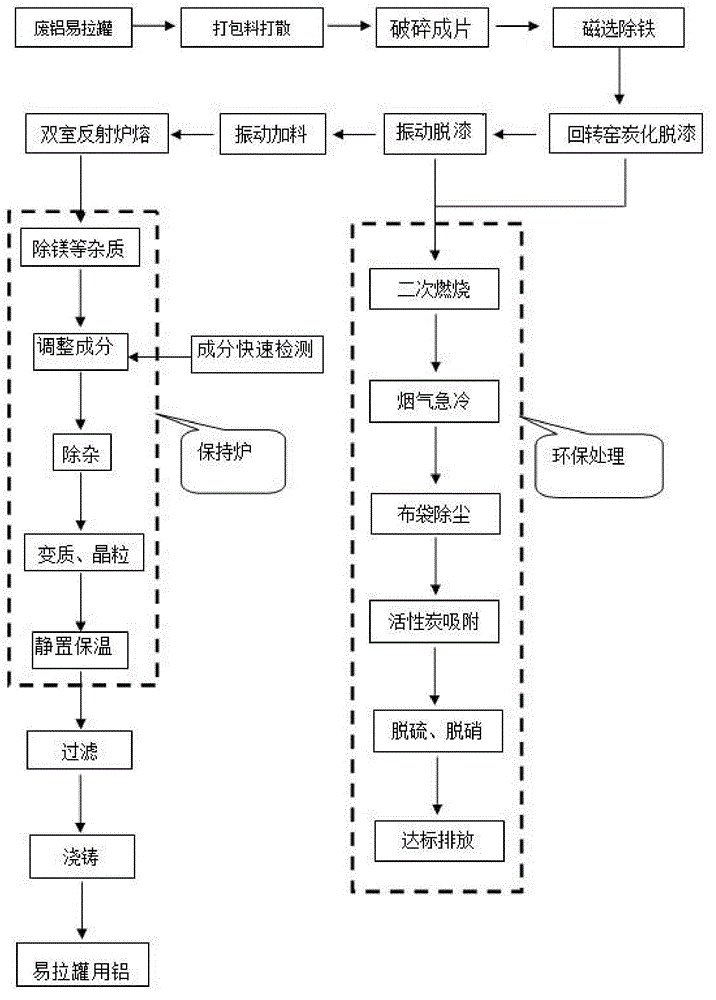

[0033] The waste aluminum cans are mechanically broken up and shredded to obtain scattered fragments, and then the ferromagnetic metals mixed in the cans are separated by a magnetic separator to avoid mixing into the subsequent process.

[0034] The can fragments were thermally depainted at an oxygen partial pressure of 8% and a temperature of 450°C for 120 minutes. The flue gas generated during the thermal stripping process is sent to the combustion furnace through the flue gas pipe, and after burning at a high temperature above 1000 ° C, the dioxins are eliminated. The flue gas temperature is rapidly cooled to below 130°C by a heat exchanger to inhibit the re-synthesis of dioxins. The cooled flue gas is treated by bag dust removal, activated carbon adsorption, and desulfurization and denitrification towers, and is discharged after meeting environmental protection requirements. The can fragments after thermal depainting are vibrated by the vibrating screen to remove the adhe...

Embodiment 2

[0041] The waste aluminum cans are mechanically broken up and shredded to obtain scattered fragments, and then the ferromagnetic metals mixed in the cans are separated by a magnetic separator to avoid mixing into the subsequent process.

[0042] The can fragments were thermally stripped for 80 minutes at an oxygen partial pressure of 0 and a temperature of 500°C. The flue gas generated during the thermal stripping process is sent to the combustion furnace through the flue gas pipe, and after burning at a high temperature above 1000 ° C, the dioxins are eliminated. The flue gas temperature is rapidly cooled to below 130°C by a heat exchanger to inhibit the re-generation of dioxins. The cooled flue gas is treated by bag dust removal, activated carbon adsorption, and desulfurization and denitrification towers, and is discharged after meeting environmental protection requirements. The can fragments after thermal depainting are vibrated by the vibrating screen to remove the adhere...

Embodiment 3

[0049] The waste aluminum cans are mechanically broken up and shredded to obtain scattered fragments, and then the ferromagnetic metals mixed in the cans are separated by a magnetic separator to avoid mixing into the subsequent process.

[0050] The can fragments were thermally depainted at an oxygen partial pressure of 4% and a temperature of 550°C for 60 minutes. The flue gas generated during the thermal stripping process is sent to the combustion furnace through the flue gas pipe, and after burning at a high temperature above 1000 ° C, the dioxins are eliminated. The flue gas temperature is rapidly cooled to below 130°C by a heat exchanger to inhibit the re-generation of dioxins. The cooled flue gas is treated by bag dust removal, activated carbon adsorption, and desulfurization and denitrification towers, and is discharged after meeting environmental protection requirements. The can fragments after thermal depainting are vibrated by the vibrating screen to remove the adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com