Environment-friendly preparation method of toluylene-based biphenyl type fluorescent brightener

A fluorescent whitening agent and biphenyl-based technology, which is applied in the direction of styrene-based dyes, etc., can solve the problems of difficult handling and large environmental pollution, and achieve the effects of convenient source, low cost, and avoiding waste of heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

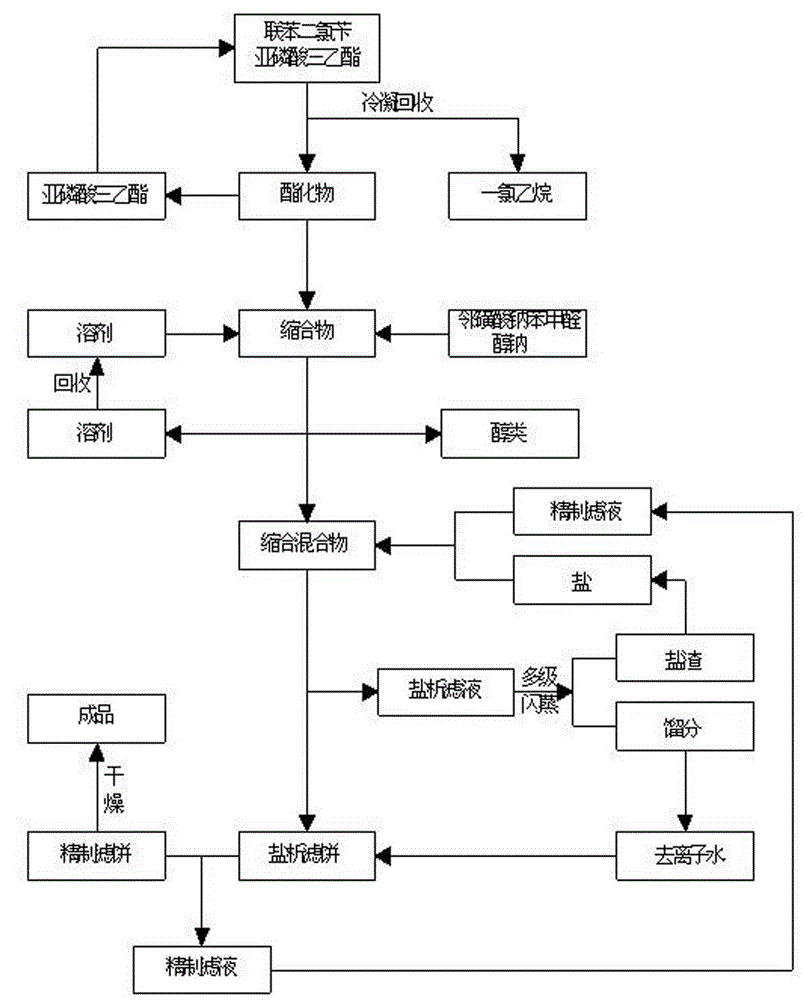

Image

Examples

Embodiment 1

[0040] Arbuzov reaction: In a dry 300mL reaction kettle, add 45.5g of biphenyl dichlorobenzyl, 60.0g of triethyl phosphite, in N 2 Slowly raise the temperature to 120-125°C within 2-3 hours under the protection of the environment, keep it warm for 4 hours, add 30.0g of triethyl phosphite, then continue to heat up to 145-155°C, keep it warm for 2 hours, add 10.0g of triethyl phosphite , reflux reaction at this temperature for 6-8 hours, stop the reaction, distill under reduced pressure, distill off excess triethyl phosphite and some by-products, lower the temperature to 40°C, and obtain a pale yellow solid ester;

[0041] Condensation reaction: In a dry 500ml reactor, add 200.0g DMF, 31.5g esterified product and 52.5g o-sulfonate sodium benzaldehyde in sequence, start stirring for 0.5 hours to basically dissolve the materials, and then control the temperature between 20-30°C , add 52.0g of sodium methoxide solution dropwise within about 4 hours, then slowly raise the temperatur...

Embodiment 2

[0045] Arbuzov reaction: In a dry 300mL reaction kettle, add 45.5g of biphenyl benzyl dichloride and 50.0g of triethyl phosphite, in N 2 Slowly raise the temperature to 120-125°C within 2-3 hours under the protection of the environment, keep it warm for 4 hours, add 40.0g of triethyl phosphite, then continue to heat up to 145-155°C, keep it warm for 2 hours, add 15.0g of triethyl phosphite , Reflux reaction at this temperature for 6-8 hours, and all the other operations are the same as in Example 1.

[0046] Condensation reaction and aftertreatment are with embodiment 1.

Embodiment 3

[0048] Arbuzov reaction: In a dry 300mL reaction kettle, add 45.5g of biphenyl dichlorobenzyl, 70.0g of triethyl phosphite, in N 2 Slowly raise the temperature to 120-125°C within 2-3 hours under the protection of the environment, keep it warm for 4 hours, add 20.0g of triethyl phosphite, then continue to heat up to 145-155°C, keep it warm for 2 hours, add 20.0g of triethyl phosphite , Reflux reaction at this temperature for 6-8 hours, and all the other operations are the same as in Example 1.

[0049] Condensation reaction and aftertreatment are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com