Device and method for controlling superheat degree of molten steel in continuous casting ladle or tundish

A tundish and superheating technology, which is applied in the configuration of casting equipment, metal processing equipment, indicating equipment/measuring equipment, etc., can solve problems such as difficult to have both heating and cooling, single heating or cooling effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

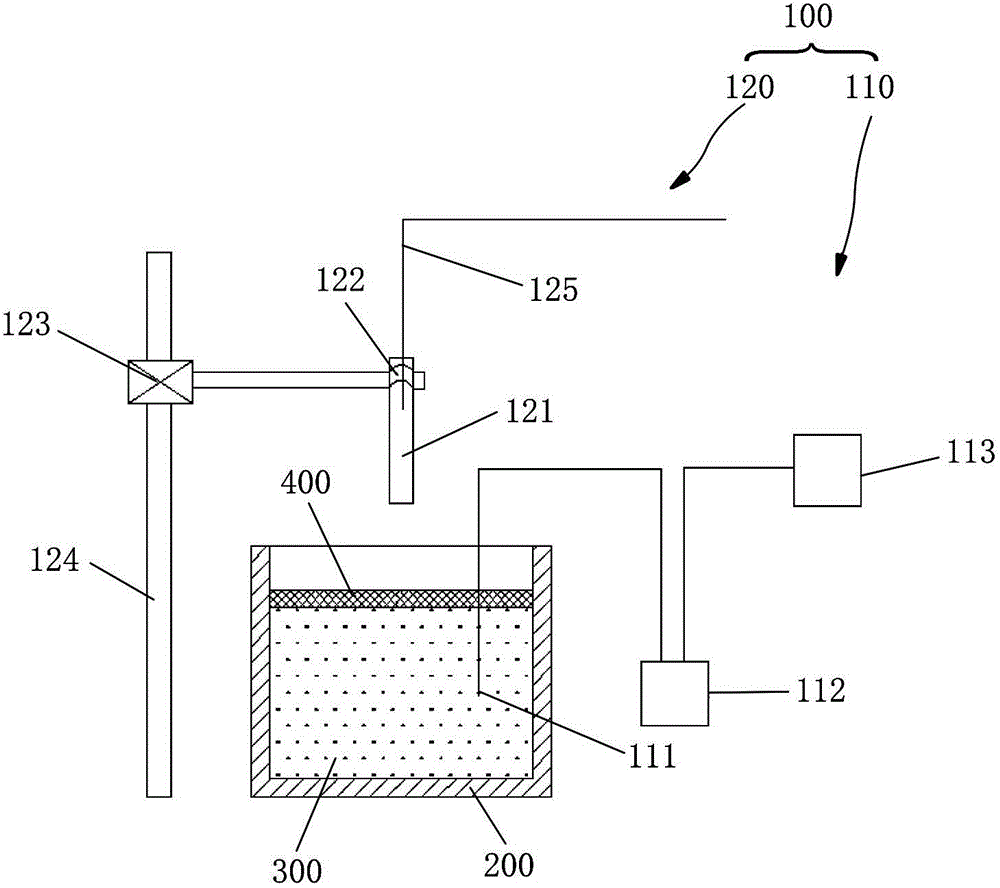

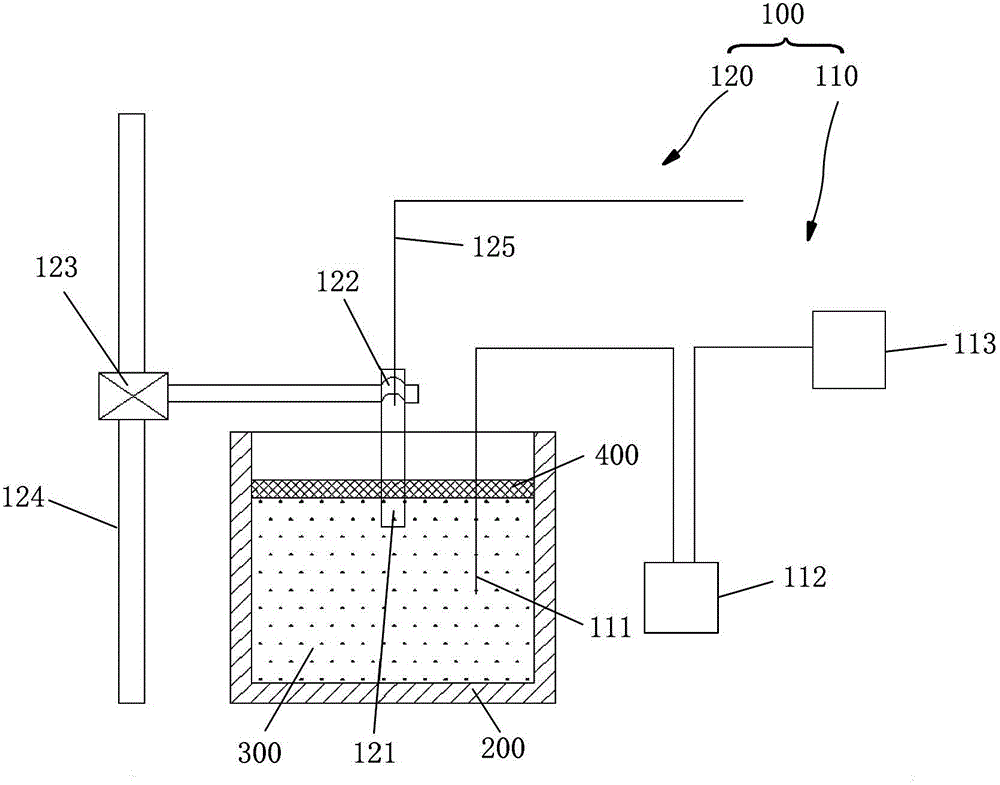

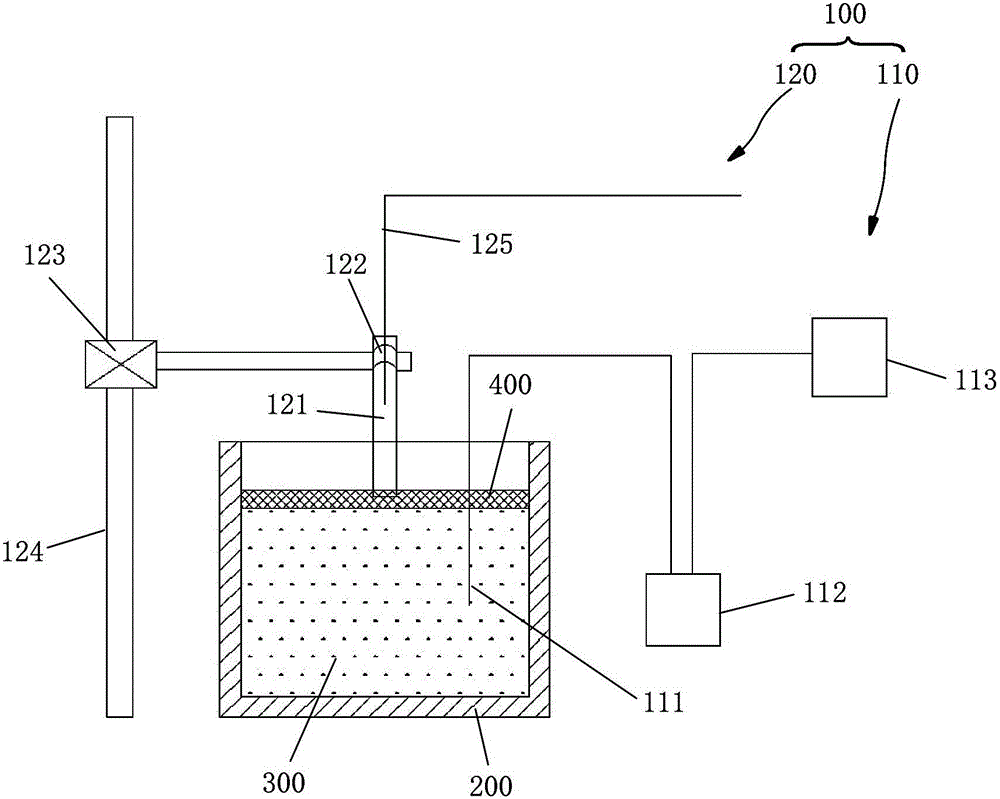

[0016] Hereinafter, an apparatus and method for controlling the degree of superheat of molten steel in a continuous casting ladle or tundish according to the present invention will be described in detail with reference to the accompanying drawings.

[0017] figure 1 is a schematic diagram showing an apparatus for controlling the degree of superheat of molten steel in a continuous casting ladle or tundish according to the present invention. refer to figure 1 , the device 100 for controlling the superheat of molten steel in a continuous casting ladle or tundish according to the present invention includes a temperature measuring device 110 for measuring the temperature of molten steel in a continuous casting ladle or a tundish and a device for controlling the temperature of a continuous casting ladle or a tundish A temperature control device 120 for the temperature of molten steel in the ladle.

[0018] The temperature measuring device 110 is used to measure the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com