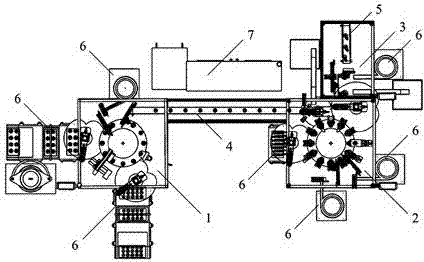

Full-automatic flexible assembly line of light emitting diode (LED) bulb lamp

A technology of LED bulb lamps and assembly lines, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to produce LED bulb lamps, automatic assembly processes and assembly actuators, etc., to improve the degree of automation and reliability, high degree of automation, and compact production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

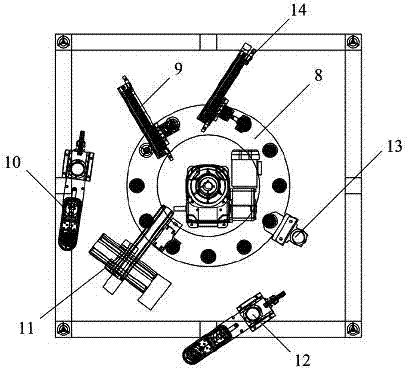

[0098] Taking the assembly of the 7-watt LED bulb lamp with E27 lamp holder as an example, the LED bulb lamp involves 7 parts, including: insulating sleeve, radiator, light source board, power board, connecting ring, lamp holder and lampshade, and its automatic assembly The craft is:

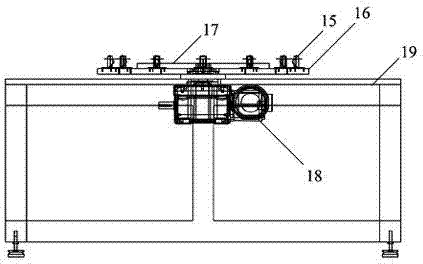

[0099] 1. The insulating sleeve feeding mechanism 40 provides the insulating sleeve, and the feeding mechanism 9 places the insulating sleeve on the tooling fixture 15 of the station turntable 8 to fix it;

[0100] 2. The radiator feeding mechanism 41 provides the radiator, and the radiator plug-in assembly mechanism 10 connects the radiator and the insulating sleeve through the bayonet;

[0101] 3. The glue-applying mechanism 11 coats the heat-conducting silicone grease on the top surface of the radiator, and the coating track is a circle;

[0102] 4. The light source board plug-in assembly mechanism 12 places the light source board on the top surface of the radiator;

[0103] 5. The locking sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com