Encapsulating structure of electronic element

An electronic component and potting technology, which is applied in the field of potting structure of high-power electronic components, can solve the problems of poor thermal conductivity of polymer heat sink parts, difficult processing of metal heat sink parts, high processing temperature of ceramic heat sink parts, etc. , to achieve the effect of improving heat dissipation, good elastic deformation capacity, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

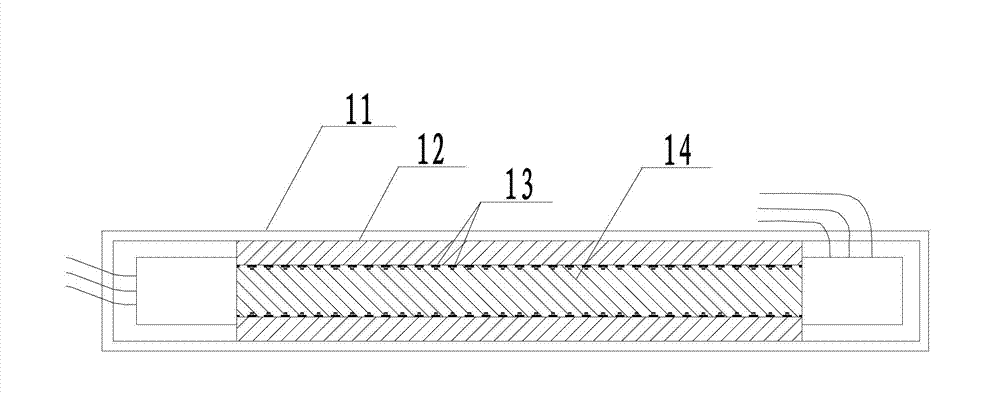

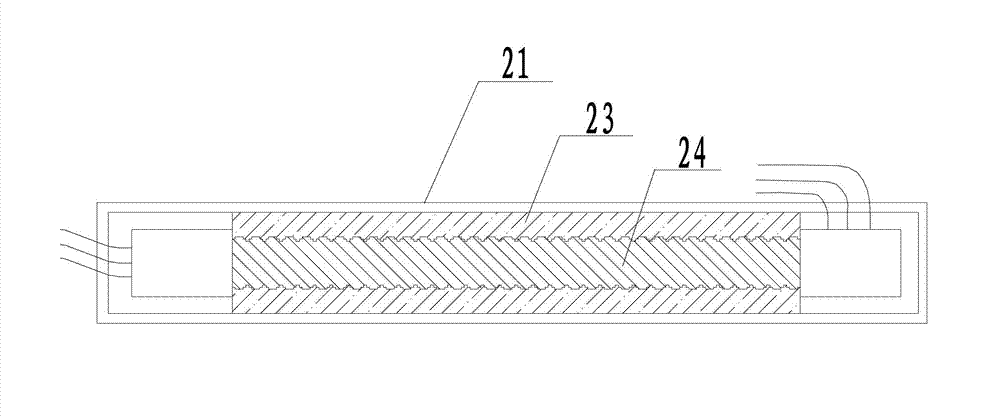

[0092] Such as figure 2 As shown, the potting structure of the traveling wave tube according to the first embodiment of the present invention includes a slow-wave component 24 and a casing 21, and a composite heat-conducting material 23 is potted between the slow-wave component 24 and the casing 21, and the composite heat-conducting material 23 Aluminum particles coated with epoxy resin; the composite thermal conductive material 23 is composed of the following components:

[0093] A, 100 parts by weight of surface galvanized and copper-plated aluminum particles, the particle diameter of the aluminum particles is 0.1mm;

[0094] B, 10 weight parts through the epoxy resin prepolymer of amide curing agent and dodecyl glycidyl ether solidification; The mass ratio of described epoxy resin and curing agent and dodecyl glycidyl ether is 1:0.1 :0.1;

[0095] C, 1 weight part polyether ketone accelerator;

[0096] D. 1 part by weight of polyethersulfone toughening agent.

Embodiment 2

[0098] Such as figure 2 As shown, the potting structure of the traveling wave tube according to the first embodiment of the present invention includes a slow-wave component 24 and a casing 21, and a composite heat-conducting material 23 is potted between the slow-wave component 24 and the casing 21, and the composite heat-conducting material 23 Aluminum particles coated with epoxy resin; the composite thermal conductive material 23 is composed of the following components:

[0099] A, 100 parts by weight of surface galvanized and copper-plated aluminum particles, the particle diameter of the aluminum particles is 10mm;

[0100] B, 10 weight parts through the epoxy resin prepolymer of amide curing agent and dodecyl glycidyl ether solidification; The mass ratio of described epoxy resin and curing agent and dodecyl glycidyl ether is 1:0.1 :0.1;

[0101] C, 1 weight part polyether ketone accelerator;

[0102] D. 1 part by weight of polyethersulfone toughening agent.

Embodiment 3

[0104] Such as figure 2 As shown, the potting structure of the traveling wave tube according to the first embodiment of the present invention includes a slow-wave component 24 and a casing 21, and a composite heat-conducting material 23 is potted between the slow-wave component 24 and the casing 21, and the composite heat-conducting material 23 Aluminum particles coated with epoxy resin; the composite thermal conductive material 23 is composed of the following components:

[0105] A, 100 parts by weight of surface galvanized and copper-plated aluminum particles, the particle diameter of the aluminum particles is 1mm;

[0106] B, 0.1 weight part through the epoxy resin prepolymer solidified by aromatic amine curing agent and n-butyl glycidyl ether; The mass ratio of described epoxy resin and curing agent and n-butyl glycidyl ether is 1:0.1:0.1;

[0107] C, 1 weight part polyether ketone accelerator;

[0108] D. 1 part by weight of polyethersulfone toughening agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com