Polyethylene glycol terephthalate antibacterial composite material and preparation technology thereof

A technology of polyethylene terephthalate and composite material, which is applied in the field of polyethylene terephthalate antibacterial composite material and its preparation technology, can solve the problem of limiting the use range of PET and failing to achieve product packaging requirements, poor antibacterial effect of PET, etc., to achieve the effect of low manufacturing cost, low processing cost and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

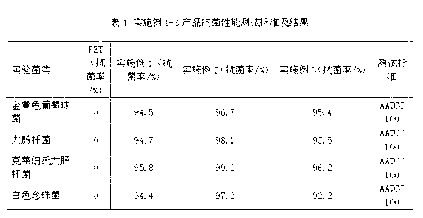

Examples

Embodiment 1

[0024] The polyethylene terephthalate antibacterial composite material of the present embodiment is made from the raw material of following parts by weight: polyethylene terephthalate 62Kg, chitosan 25Kg, silver series inorganic antibacterial agent HN -300 is 10Kg, stearic acid is 2Kg, and antioxidant 1010 is 1Kg.

[0025] Its preparation process comprises the following steps:

[0026] (1) Weigh the raw materials according to the above ratio of parts by weight, then place them in a high-speed mixer and mix them for 10 minutes;

[0027] (2) Melt and extrude the mixed raw materials in step (1) in a co-rotating parallel twin-screw extruder, and granulate. The processing parameters are as follows: the temperature of the first zone is 235°C, the temperature of the second zone is 255°C, and the temperature of the third zone is 260°C ℃, the temperature in the fourth zone is 265 ℃, the temperature in the fifth zone is 270 ℃, the temperature in the sixth zone is 275 ℃, the temperature...

Embodiment 2

[0031] The polyethylene terephthalate antibacterial composite material of the present embodiment is made from the raw material of following parts by weight: polyethylene terephthalate 67Kg, chitosan 20Kg, silver series inorganic antibacterial agent HN -300 is 10Kg, stearic acid is 2Kg, and antioxidant 1010 is 1Kg.

[0032] Its preparation process comprises the following steps:

[0033] (1) Weigh the raw materials according to the above weight ratio, then place them in a high-speed mixer and mix them for 10 minutes;

[0034] (2) The raw materials mixed in step (1) are melted and extruded in the parallel twin-screw extruder, and granulated. The processing parameters are as follows: the temperature of the first zone is 235°C, the temperature of the second zone is 255°C, and the temperature of the third zone 260°C, 265°C in zone 4, 270°C in zone 5, 275°C in zone 6, 260°C in zone 7, 260°C in zone 8, 260°C in zone 9, 255°C melt temperature, 265°C head temperature , residence time ...

Embodiment 3

[0038] The polyethylene terephthalate antibacterial composite material of the present embodiment is made from the raw material of following parts by weight: polyethylene terephthalate 72Kg, chitosan 15Kg, silver series inorganic antibacterial agent HN -300 is 10Kg, polyethylene wax is 2Kg, antioxidant 168 is 1Kg.

[0039] Its preparation process comprises the following steps:

[0040] (1) Weigh the raw materials according to the above weight ratio, then place them in a high-speed mixer and mix them for 10 minutes;

[0041] (2) Melt and extrude the mixed raw materials in step (1) in a co-rotating parallel twin-screw extruder, and granulate. The processing parameters are as follows: the temperature of the first zone is 235°C, the temperature of the second zone is 255°C, and the temperature of the third zone is 260°C ℃, the temperature in the fourth zone is 265 ℃, the temperature in the fifth zone is 270 ℃, the temperature in the sixth zone is 275 ℃, the temperature in the seven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com