Preparation method of porous lithium iron phosphate powder

A technology of lithium iron phosphate and powder, which is applied in the field of preparation of lithium-ion battery cathode materials, can solve problems such as uneven carbon coating, low product purity, and segregation of precursor components, and achieve good electrochemical performance and rate performance , The effect of simple process

Inactive Publication Date: 2013-01-16

LANZHOU UNIVERSITY OF TECHNOLOGY

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the preparation process of lithium iron phosphate described in this patent has the following deficiencies: First, the preparation of Fe(OH) is not removed during the preparation process. 3 SO introduced during colloid 4 2- , NO 3 - , Cl - and other anionic impurities, these anionic impurities have a great impact on the electrochemical performance of the final product; second, the vacuum drying method used is likely to cause segregation of the precursor composition, which eventually leads to uneven carbon coating and low product purity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

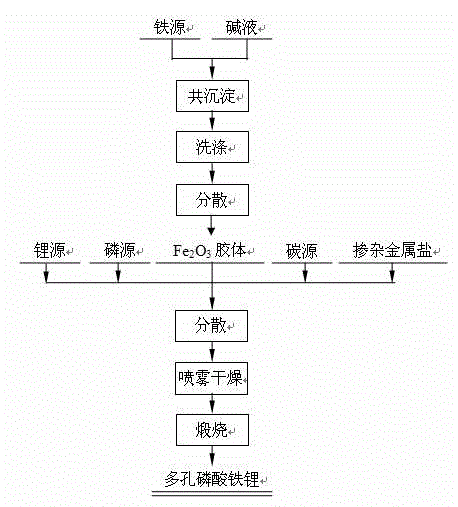

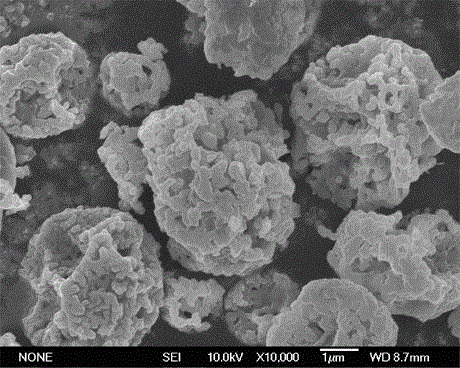

Disclosed is a preparation method of porous lithium iron phosphate powder. The preparation method includes dissolving trivalent iron salt into water and preparing solution; adding alkali liquor in the boiling state to obtain Fe(OH)3 nano particles, dispersing the Fe(OH)3 nano particles in the water after washing, forming iron sesquioxide colloid with stirring intensively; adding a water-soluble lithium source, a phosphorus source, a carbon source and doped ion compound into the iron sesquioxide colloid, intensively stirring to form colloid-shaped mixed pulp uniformly molecularly mixed; drying the pulp by mist and obtaining spherical lithium iron phosphate precursor with average grain diameter ranging from D50=2-3 micrometers; sintering the precursor in the inertia atmosphere at the temperature of 300-500 DEG C for 2-10 hours, and sintering the precursor again at the temperature of 500-800 DEG C for 2-12 hours and obtaining carbon-coated spherical porous lithium iron phosphate powder with average grain diameter of D50=2-3 micrometers.

Description

technical field [0001] The invention relates to lithium iron phosphate powder, a preparation method of a positive electrode material of a lithium ion battery. Background technique Lithium iron phosphate batteries have the advantages of rich raw materials, environmental friendliness, high potential and theoretical specific capacity, stable discharge voltage, good cycle performance, high safety and thermal stability, etc., and are considered to be the most widely used lithium-ion power batteries , has a broad market prospect in the fields of electric vehicles, hybrid electric vehicles, electric tools, energy storage power stations and other fields. However, the ionic conductivity and electronic conductivity of lithium iron phosphate are both low, so it is only suitable for charging and discharging at low current density. application of materials. At home and abroad, a large number of researches on the modification of lithium iron phosphate have been carried out to improve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/58

CPCY02E60/12Y02E60/10

Inventor 朱福良蒙延双

Owner LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com