Model prediction based cut tobacco dryer outlet moisture control method

A technology of export moisture and model prediction, applied in the treatment of tobacco, tobacco, application, etc., can solve the problems of large control fluctuation, reduce tobacco quality, moisture control fluctuation, etc., so as to suppress the export moisture fluctuation, avoid manual intervention, and reduce shredding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, work flow, and use methods of the present invention achieve the purpose and effect easily understood, the present invention will be further described below in conjunction with specific embodiments.

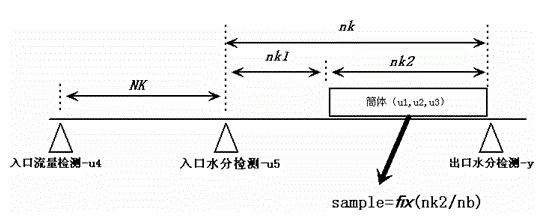

[0022] 1. The timing relationship of the process variables of the silk drying machine is as follows: figure 1 shown. Before the shredded tobacco arrives from the previous process, first detect the instantaneous flow value of the shredded tobacco at the position far from the drum of the shred dryer, that is, u4; after the NK time, come to the position u5 to detect the inlet water at this time Point value; after nk1 time, the shredded tobacco enters the drum, and the process of running in the drum will detect the damp damper, hot air temperature, cylinder temperature and cylinder motor frequency at each sampling moment; finally, after At the time of nk2, the shredded tobacco comes out of the barrel, and the outlet mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com