Para-aramid paper and preparation method thereof

A technology of para-aramid paper and para-aramid fiber, which is applied in the field of papermaking, can solve the problem of affecting the bonding properties of aramid fibers, the insulating strength of aramid paper, the decrease in breaking strength and breaking strength of aramid fibers, and the inability to fully reflect the high fiber strength, High mold and other problems, to achieve the effect of promoting development, reducing paper gaps, and filling paper gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

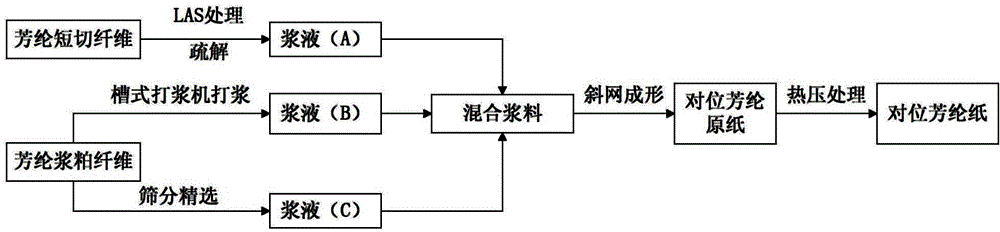

[0022] The preparation method of para-aramid fiber paper of the present invention, as figure 1 As shown, specifically follow the steps below:

[0023] Step 1: Use volume-molar concentration of aramid chopped fiber to be 1.5×10 -3 ~3.0×10 -3 mol / L, the temperature is 40 ~ 90 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water for later use.

[0024] Step 2: Thinning the washed and pretreated para-aramid chopped fibers with a trough beater to make a slurry (A).

[0025] Step 3: The para-aramid pulp fiber is subjected to beating treatment with a trough beater, and the beating degree is controlled at 30-60°SR to prepare a slurry (B).

[0026] Step 4: Sieve and select the para-aramid pulp fiber to obtain a pulp component with a mesh number of 50-100, and mix two kinds of pulp with different mesh numbers to prepare a slurry (C).

[0027] Step 5: Add the slurries (A), (B), and (C) into the slurry mixing tank according to the wei...

Embodiment 1

[0029] The volume-molar concentration of aramid chopped fiber is 2×10 -3mol / L, the temperature is 60 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water for later use; Decompose, make slurry (A); Utilize the para-aramid pulp fiber to carry out beating treatment with the trough beater, beating degree is controlled at 35 ° SR, make slurry (B); Make the para-aramid pulp fiber Sieve and select the slurry components with 50-100 mesh numbers, mix two kinds of slurry with different mesh numbers to make slurry (C); prepare 20 parts by weight of slurry (A) (hereinafter referred to as parts), slurry (B) 70 parts and 10 parts of (C) are added to the slurry mixing kettle: after adding polyethylene oxide equivalent to 0.6% of the weight of para-aramid dry fiber, the slurry is mixed and the slurry concentration is adjusted to 0.10%. The good pulp is formed on the inclined wire paper machine, pressed under the pressure of 2-5MPa for 1-5min...

Embodiment 2

[0031] The volume-molar concentration of aramid chopped fiber is 1.5×10 -3 mol / L, the temperature is 70 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water for later use; Slurry (A) is obtained by thawing; the para-aramid pulp fiber is subjected to beating treatment with a trough beater, and the beating degree is controlled at 45°SR to make a slurry (B); the para-aramid pulp fiber is screened Select the slurry components of 50-100 mesh, mix two kinds of slurry with different mesh to make slurry (C); prepare slurry (A) 30 (parts by weight, hereinafter referred to as part), slurry (B) 50 Parts, (C) 20 parts are added to the pulping kettle: add polyethylene oxide equivalent to 1.0% of the weight of para-aramid absolute dry fiber, mix the pulp and adjust the pulp concentration to 0.08% of the pulp suspension, and prepare the The slurry is formed on the inclined wire paper machine, pressed for 1-5 minutes at a pressure of 2-5 MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com