Electrode for carbon dioxide electroreduction and preparation method thereof

A carbon dioxide, electrode technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., to achieve high electroreduction activity and stability, improve current density, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

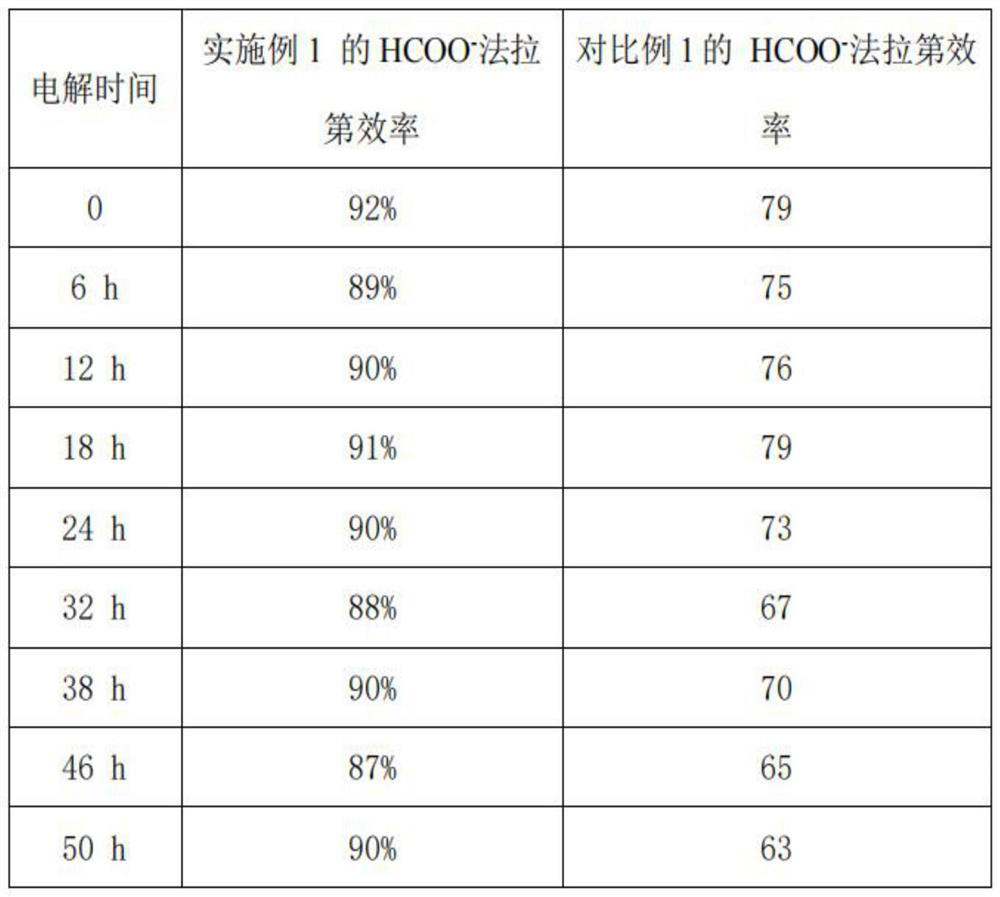

Embodiment 1

[0035] A 200 μm copper mesh was used as the base, cleaned with acetone and hydrochloric acid, and then placed in NH 3 ·H 2 O and (NH 4 ) 2 S 2 O 8 The oxidizing solution with a molar ratio of 8:1 was treated for 8 min. After cleaning, it is used as the base layer; the amino cellulose solution with a concentration of 0.2% is prepared, and diethylamino cellulose is sprayed by spraying method to the surface of the base layer, and the loading amount of the transition layer is 0.3 mg / cm 2 . The electrodes after spraying were placed in a vacuum oven to dry at 100 °C for 6 h. SnCl 2 Mixed with hydrochloric acid and water to prepare SnCl with a concentration of 0.2mol / L 2 The aqueous solution is mixed with 0.6 mol / L NaF and 0.10 mol / L ethylenediaminetetraacetic acid, and then 0.09 mol / L sodium citrate is added to obtain an electroplating solution, and the pH value is adjusted at 4 by using hydrochloric acid. The molar ratio of Sn to EDTA is 8:1 and the molar ratio of NaF to S...

Embodiment 2

[0053] A 200 μm copper mesh was used as the base, cleaned with acetone and hydrochloric acid, and then placed in NH 3 ·H 2 O and (NH 4 ) 2 S 2 O 8 The oxidizing solution with a molar ratio of 8:1 was treated for 8 min. After cleaning, it is used as the base layer; the amino cellulose solution with a concentration of 0.2% is prepared, and p-aminobenzyl cellulose is sprayed on the surface of the base layer, and the loading amount of the transition layer is 0.3 mg / cm 2 . The electrodes after spraying were placed in a vacuum oven to dry at 100 °C for 6 h. SnCl 2 Mixed with hydrochloric acid and water to prepare SnCl with a concentration of 0.2mol / L 2 The aqueous solution is mixed with 0.6 mol / L NaF and 0.10 mol / L iminodiacetic acid evenly, then 0.09 mol / L sodium citrate is added to obtain an electroplating solution, and the pH value is adjusted at 4 with hydrochloric acid. The molar ratio of Sn to iminodiacetic acid is 8:1 and the molar ratio of NaF to Sn is 15:1. Under ...

Embodiment 3

[0055] A 200 μm copper mesh was used as the base, cleaned with acetone and hydrochloric acid, and then placed in NH 3 ·H 2 O and (NH 4 ) 2 S 2 O 8 The oxidizing solution with a molar ratio of 8:1 was treated for 8 min. After cleaning, it is used as the base layer; the amino cellulose solution with a concentration of 0.2% is prepared, and diethylamino cellulose is sprayed by spraying method to the surface of the base layer, and the loading amount of the transition layer is 0.5 mg / cm 2 . The electrodes after spraying were placed in a vacuum oven to dry at 100 °C for 6 h. SnCl 2 Mixed with hydrochloric acid and water to prepare SnCl with a concentration of 0.2mol / L 2 The aqueous solution is mixed with 0.6 mol / L NaF and 0.10 mol / L iminodiacetic acid evenly, then 0.09 mol / L sodium citrate is added to obtain an electroplating solution, and the pH value is adjusted at 4 with hydrochloric acid. The molar ratio of Sn to EDTA was 8:1, and the molar ratio of NaF to Sn was 15:1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com