Device for growing tellurium-zinc-cadmium crystals by traveling heater method

A cadmium zinc telluride and heater technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem of reducing μτ, reduce contamination, increase crystal single crystal volume and yield, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

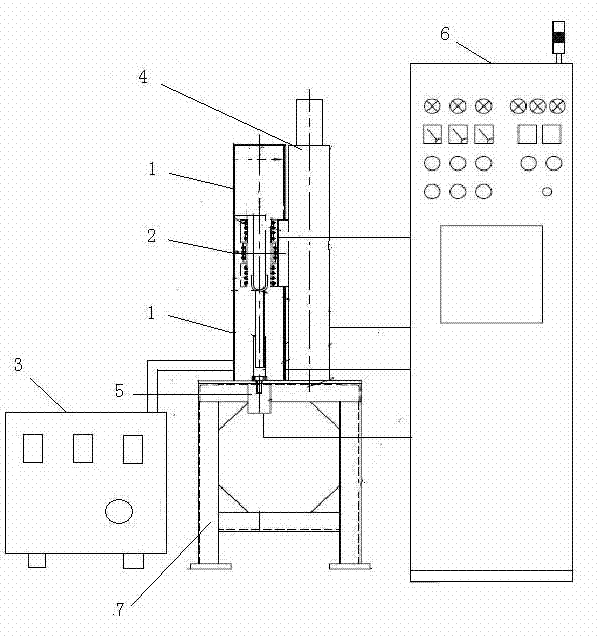

[0015] see figure 1 The device for growing cadmium zinc telluride crystals by moving the heater method in this embodiment includes a furnace frame 7, a growth furnace body arranged above the furnace frame 7, and a quartz material tube loaded with cadmium zinc telluride crystal growth materials is placed on an alumina support rod , the alumina support rod is placed in the growth furnace body, the circulating cooling water system 3 and the Soshu growth furnace body jointly control the temperature of the crystal growth process, the growth furnace body is installed vertically, and the middle heating section of the growth furnace body is equipped with high-frequency electromagnetic induction Heater 2, the upper and lower sections of the growth furnace body are the upper and lower resistance heating furnaces 1, and the upper and lower resistance heating furnaces 1 form the heat preservation area in the middle heating section of the growth furnace body, and the bottom end of the alumi...

Embodiment 2

[0019] The technical solution of this embodiment is basically the same as that of Embodiment 1, especially in that:

[0020] In this embodiment, the temperature of the high-frequency electromagnetic induction heater 2 is set to 800° C., and the cadmium zinc telluride crystal growth material is kept warm in the growth furnace for 24 hours to finally obtain the cadmium zinc telluride crystal.

Embodiment 3

[0022] The technical solutions of this embodiment are basically the same as those of the foregoing embodiments, and the special features are:

[0023] In this embodiment, the growth furnace body is raised at a speed of 0.05mm / h, and at the same time, the quartz material tube loaded with the CdZnTe crystal growth material is rotated at a constant speed by the alumina support rod at a speed of 15r / min, and finally the CdZnTe crystal growth material is obtained. crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com