High-strength plastic floor tile

A high-strength, plastic technology, applied in the field of plastic floor tiles, can solve the problems of affecting performance, weak impact resistance, deformation, etc., and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

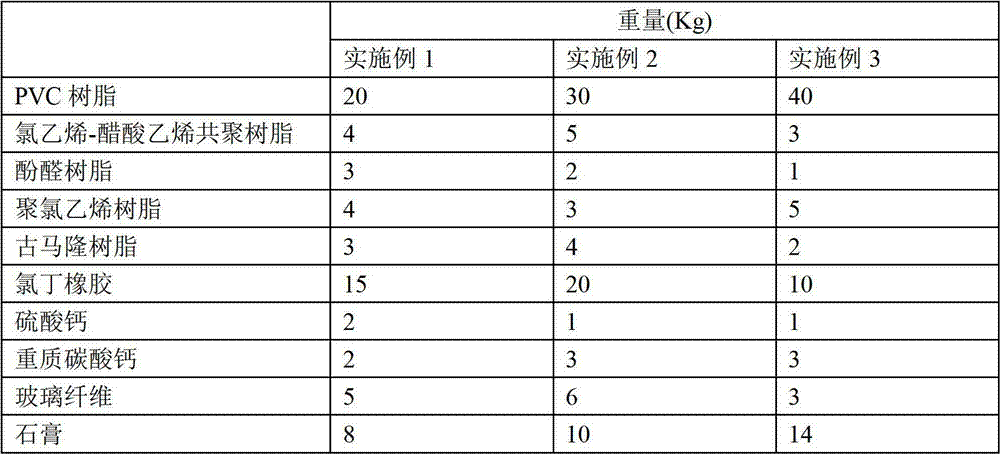

Examples

Embodiment 1

[0030] S1: Put the raw materials of each component in a kneading pot and mix them evenly;

[0031] S2: Mixing is carried out in an internal mixer, and the mixing temperature is 130°C;

[0032] S3: Send the above kneaded material to the kneading roll for pre-calendering, and the roll temperature is 90°C;

[0033] S4: Put the pre-compressed sheet on a calender roll at 80° C. for calendering, cooling, punching and forming.

Embodiment 2

[0035] The difference from Example 1 is: the temperature in step S2 is 135° C.; the temperature in step S3 is 95° C.; the temperature in step S4 is 85° C.

Embodiment 3

[0037] The difference from Example 1 is: the temperature in step S2 is 140° C.; the temperature in step S3 is 100° C.; the temperature in step S4 is 90° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com