Diclofenac sodium sustained-release capsule and preparation method thereof

A technology of diclofenac sodium and sustained-release capsules, which is applied in the field of medicine, can solve the problems of many types and components of excipients, and the release degree and stability need to be further improved, and achieve the effects of excellent release curve, maintaining effective concentration and increasing curative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

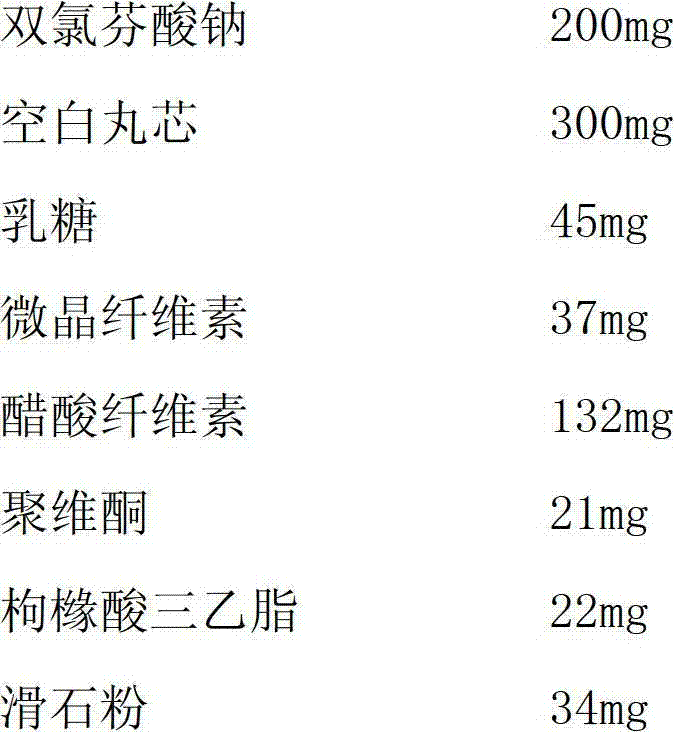

[0025] Example 1 Diclofenac Sodium Sustained Release Capsules Prescription Composition and Preparation Method

[0026]

[0027] The preparation steps are:

[0028] (1) 1g hypromellose K30 is added to 4.5 times the weight of 95% ethanol, stirred and dissolved; the prescription amount of diclofenac sodium is added to the above solution, stirred and dissolved;

[0029] (2) Add 150g blank pellet cores to the granulator, turn on the temperature and compressed air, and slowly spray the medicinal solution (1) onto the blank pellet cores to prepare drug-containing pellet cores;

[0030] (3) dissolving 10g ethyl cellulose and 2g diethyl phthalate, 4.5g talcum powder, 2g hypromellose with 10 times the weight of 95% ethanol solution to make a slow-release coating solution;

[0031] (4) Evenly spray the prepared sustained-release coating solution (3) on the surface of the prepared drug-containing pellets, and then place the obtained sustained-release pellets in a vacuum drying oven at...

Embodiment 2

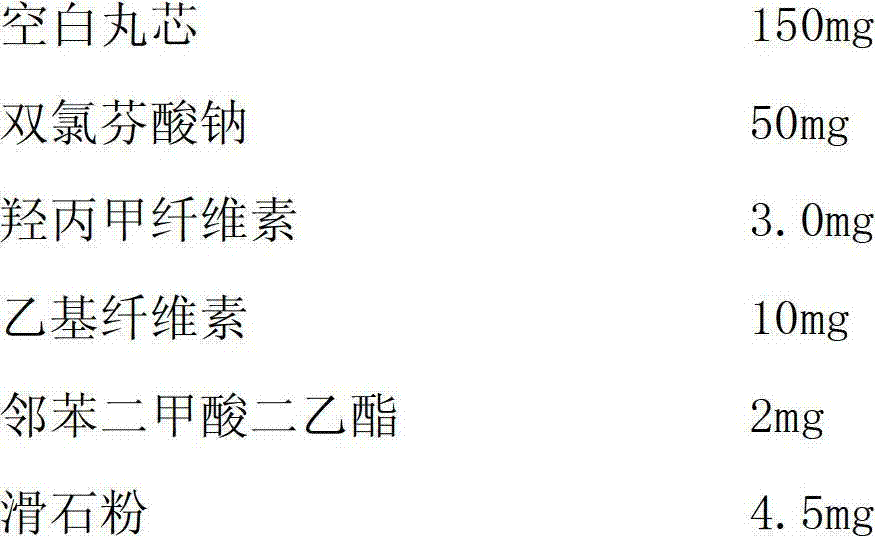

[0033] Example 2 Diclofenac Sodium Sustained Release Capsules Prescription and Preparation Method

[0034]

[0035] The preparation steps are:

[0036] (1) 1.8g hypromellose K30 is added to 4.5 times the weight of 95% ethanol, stirred and dissolved; the prescription amount of diclofenac sodium is added to the above solution, stirred and dissolved;

[0037] (2) Add 150g blank pellet cores to the granulator, turn on the temperature and compressed air, and slowly spray the medicinal solution (1) onto the blank pellet cores to prepare drug-containing pellet cores;

[0038] (3) dissolving 15g cellulose acetate, 3g triethyl citrate, 5g magnesium stearate, 3.6g hypromellose with 11 times the weight of 95% ethanol solution to make a slow-release coating solution;

[0039](4) Sprinkle the prepared sustained-release coating solution (3) evenly on the surface of the prepared drug-containing pellets, and then place the obtained sustained-release pellets in a vacuum drying oven at 70°C...

Embodiment 3

[0041] Example 3 Diclofenac Sodium Sustained Release Capsules Prescription and Preparation Method

[0042]

[0043] The preparation steps are:

[0044] (1) 2g hypromellose is added in 95% ethanol of 3.5 times of weight, stirring and dissolving; Diclofenac sodium of recipe quantity is added in the above-mentioned solution, stirring and dissolving;

[0045] (2) Add 150g blank pellet cores to the granulator, turn on the temperature and compressed air, and slowly spray the medicinal solution (1) onto the blank pellet cores to prepare drug-containing pellet cores;

[0046] (3) Dissolve 15g of cellulose acetate and 3g of triacetin, 5g of micropowdered silica gel, and 6g of hypromellose with 95% ethanol solution of 10 times the weight to make a slow-release coating solution;

[0047] (4) Sprinkle the prepared sustained-release coating solution (3) evenly on the surface of the prepared drug-containing pellets, and then place the obtained sustained-release pellets in a vacuum dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com