Organic electroluminescence device and preparation method thereof

An electroluminescent device and luminescent technology, which are applied in the fields of electric solid-state devices, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems such as aging and failure of functional layer materials, shortening the life of organic electroluminescent devices, etc. Achieve the effect of slowing down the progress of aging and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Another object of the present invention is to provide a method for preparing the above-mentioned organic electroluminescent device, the steps of which are as follows:

[0041] S1, cleaning the anode substrate, and then performing activation treatment on the surface of the anode layer of the anode substrate;

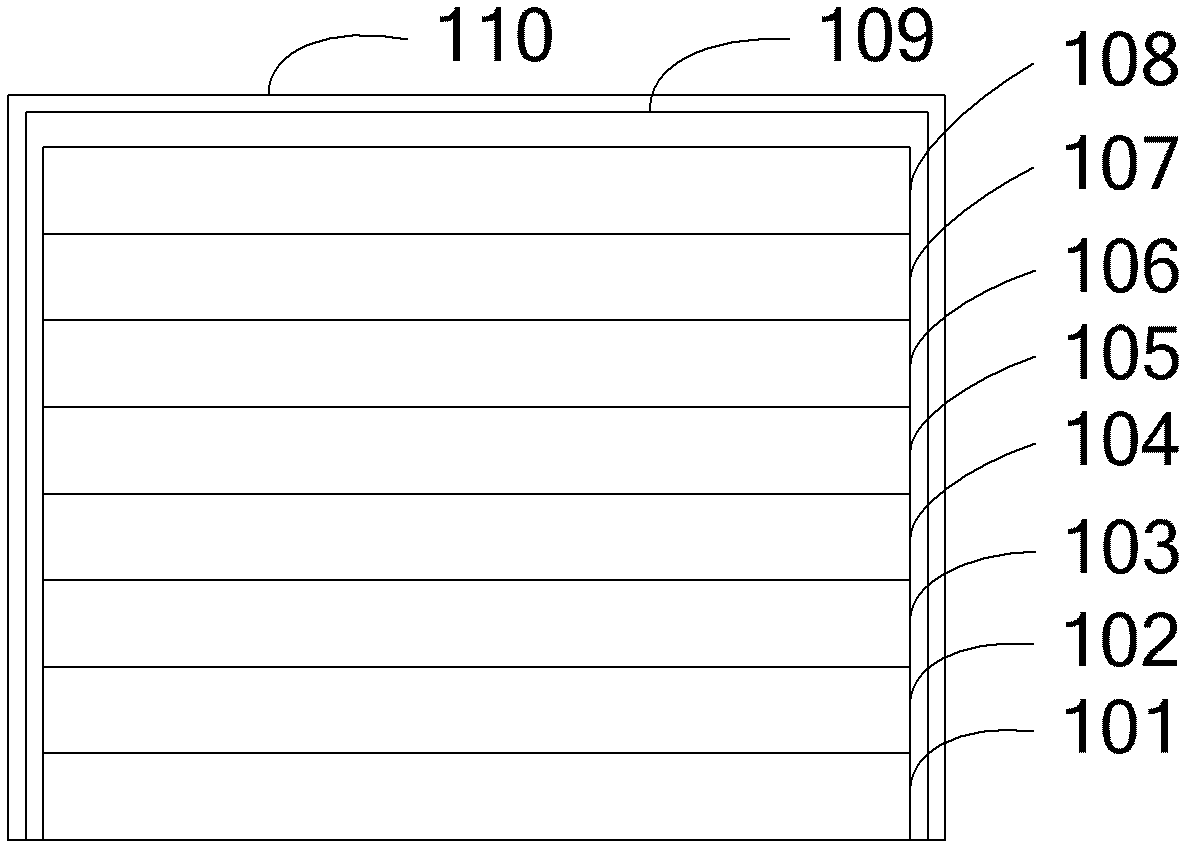

[0042]S2. Using the method of vacuum evaporation or solution coating, sequentially prepare functional layers on the surface of the anode layer of the anode substrate, such as a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron injection layer, a cathode layer, and the thicknesses of the hole injection layer, hole transport layer, light emitting layer, electron transport layer and electron injection layer are 10-15nm, 40-60nm, 10-50nm, 20-80nm, 1-2nm; Wherein, the cathode layer is a sandwich layer structure of ZnS-Ag-ZnS, and the thickness of the ZnS layer is 30nm, the thickness of the Ag layer is 10nm, an...

Embodiment 1

[0052] The organic electroluminescent device of the present embodiment has the following structure:

[0053] ITO glass / MoO 3 / NPB / TPBi:FIrpic / Alq3 / LiF / ZnS-Ag-ZnS / MgF 2 / ZnS / PET.

[0054] 1. Wash the substrate of ITO glass (wherein, ITO, i.e., indium tin oxide, is the anode layer and plays a conductive role; the glass is the substrate; ITO glass is obtained by purchasing) sequentially with detergent, ethanol, acetone, and pure water, and each In the cleaning stage, the ultrasonic cleaning machine is used for cleaning, each cleaning is 5 minutes, and the method is repeated for 5 minutes, respectively, and then dried in an oven for use;

[0055] 2. Perform surface activation treatment on the cleaned ITO glass to increase the oxygen content of the ITO surface layer and improve the work function of the ITO surface; the thickness of ITO is 100nm;

[0056] 3. Using the method of vacuum evaporation or solution coating, sequentially prepare a hole injection layer, a hole transport l...

Embodiment 2

[0063] The organic electroluminescent device of the present embodiment has the following structure:

[0064] ITO glass / WO 3 / TPD / TPBi:Ir(ppy) 3 / Alq3 / LiF / ZnS-Ag-ZnS / Alq3 / ZnSe / PET.

[0065] 1. Wash the substrate of ITO glass (wherein, ITO, i.e., indium tin oxide, is the anode layer and plays a conductive role; the glass is the substrate; ITO glass is obtained by purchasing) sequentially with detergent, ethanol, acetone, and pure water, and each In the cleaning stage, the ultrasonic cleaning machine is used for cleaning, each cleaning is 5 minutes, and the method is repeated for 5 minutes, respectively, and then dried in an oven for use;

[0066] 2. Perform surface activation treatment on the cleaned ITO glass to increase the oxygen content of the ITO surface layer and improve the work function of the ITO surface; the thickness of ITO is 100nm;

[0067] 3. Using the method of solution coating, a hole injection layer, a hole transport layer, a light-emitting layer, an electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com